The world has a lot of plastic. It floats in our oceans, killing sea life. It sits in our landfills, resolutely refusing to break down. We are drowning in the stuff… and we keep making more of it.

Typically, fiber manufacturers use non-recycled plastic to create polyester. Polyester starts as a fossil fuel.

But things are starting to change. Mills all over the world are taking post-consumer plastic — the stuff in your recycling bin right now — and transforming it into the high-quality, durable, functional fiber.

Plastic’s durability can be its greatest liability. Or, if we give existing plastics new life, durability can be its greatest strength.

You’ve probably seen tons of products made from recycled plastic — perhaps leggings, or shoes, or puffy coats.

What is Repreve?

Repreve, made by Unifi, is a family of synthetic fibers containing recycled materials. It is a polyester fiber. Unifi’s U Trust™ verification program ensures that Repreve recycled fibers are traceable, transparent, and most importantly, certifiably sustainable. With Unifi’s Fiberprint™ technology, products made from fabrics with Repreve are tested and certified before the Repreve brand name can be used. So, if you see the Repreve name, you have assurance that it’s recycled.

The Process of Creating Recycled Fiber:

Going from the contents of your recycling bin to a high-quality fiber is a lengthy process.

Cleaning and Sorting:

Plastic bottles come to recycling facilities in “bales” – large compressed cubes that are sort of like hay bales, but… plastic. The bales are loaded onto a machine and taken apart. The plastic is first sorted into different colours. Coloured Plastic, Clear plastic is more versatile and can be repurposed as fabric. Once the plastic is sorted by colour, the labels and bottle caps are removed, and the plastic goes through the first round of cleaning.

Flaking:

Once clean, the individual bottles are shredded into flakes – 1cm wide chips of plastic. Flaking allows for a quicker and more even melting process, reducing energy expended via heat and improving consistency (and therefore quality). You know how you chop a bar of chocolate before melting it for baking because melting the entire bar takes longer and the result would be clumpy and inconsistent? Same idea.

Melting and Chipping:

The flakes are washed and dried, then heated to a liquid state. The liquid plastic is pressed through a machine. The strands are cooled and cut into small pieces called “chips”. The chipping process removes all the air bubbles and moisture from the plastic to ensure a higher level of strength and durability at the fiber level. Moisture or air bubbles can mean yarn breakage. And we don’t want that.

Extrusion:

The short strands of plastic are melted down and formed again, this time into ultra-fine strands called filaments. The filaments are formed via a machine that looks like a showerhead and cooled on the way down.

Spinning:

The filaments are spun into yarn, texturized, and wound onto spools. The spools are then shipped to a mill that weaves the fiber into a finished fabric.

The Environmental Impact:

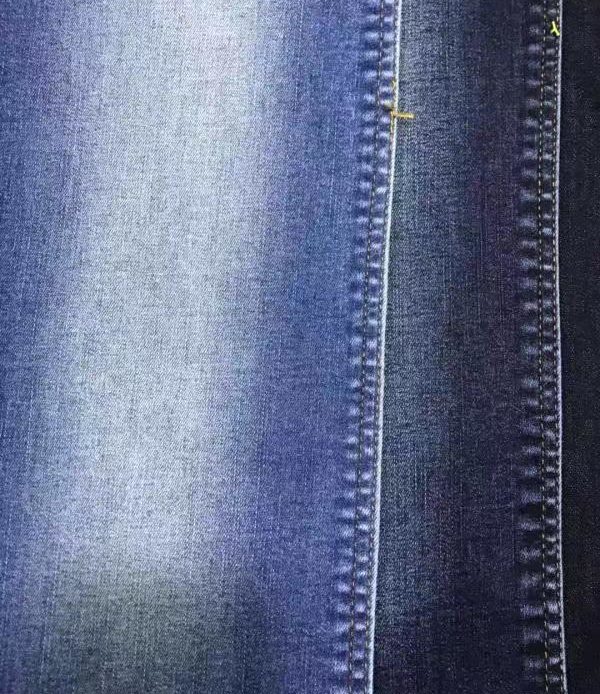

Obviously, using recycled plastic to make polyester reduces the amount of non-recyle plastic in the world. Below are some of the denim fabric that we made using reprieve. It looks like just normal denim, so you do not sacrifice any aesthetic look of the garment and you can be more environment-friendly too.

Producing one pound of Repreve…

Saves enough energy to run a compact fluorescent light bulb for nearly 22 days

Saves enough water to provide more than the daily drinking water for one person

Saves the amount of greenhouse gas (GHG) emitted while driving a hybrid car almost 3 miles

Recycled polyester versus virgin polyester:

Reduces energy consumption by 45%

Reduces water consumption by nearly 20%

Reduces greenhouse gas emissions by over 30%

All of that without sacrificing quality, durability, or performance.