You might notice more brands talking about the small-batch revolution. Small businesses now have a real shot at building unique identities and reaching new customers. Lean 4.0 practices in small-batch manufacturing help boost sustainability by saving resources and cutting waste, which lines up with global goals. Take a look at the new opportunities opening up for niche brands:

Opportunity Type | Description |

|---|---|

Authenticity and Storytelling | Younger consumers value personal narratives and connections to the origin of products. |

Demand for Health-Conscious Ingredients | Strong preference for clean-label products and transparency. |

Environmental and Social Responsibility | Consumers favor brands that show sustainability and ethical sourcing. |

Adventurous Flavor Exploration | Interest is growing in bold, innovative flavors beyond traditional options. |

Still, finding the right factory can feel tough. Micro-brands often face pushback from communities and must navigate new rules and infrastructure needs. You can overcome these hurdles with education and open communication.

Key Takeaways

Small-batch production allows brands to create unique products while reducing waste, supporting sustainability.

Younger consumers value authenticity; sharing your brand’s story can help you connect with them.

Focus on quality and sustainability to stand out in a crowded market and build customer trust.

Overcome sourcing challenges by selecting suitable suppliers and maintaining open communication.

Use online platforms to find small-batch factories that align with your values and production needs.

The Small-Batch Revolution Explained

What Is Small-Batch Production?

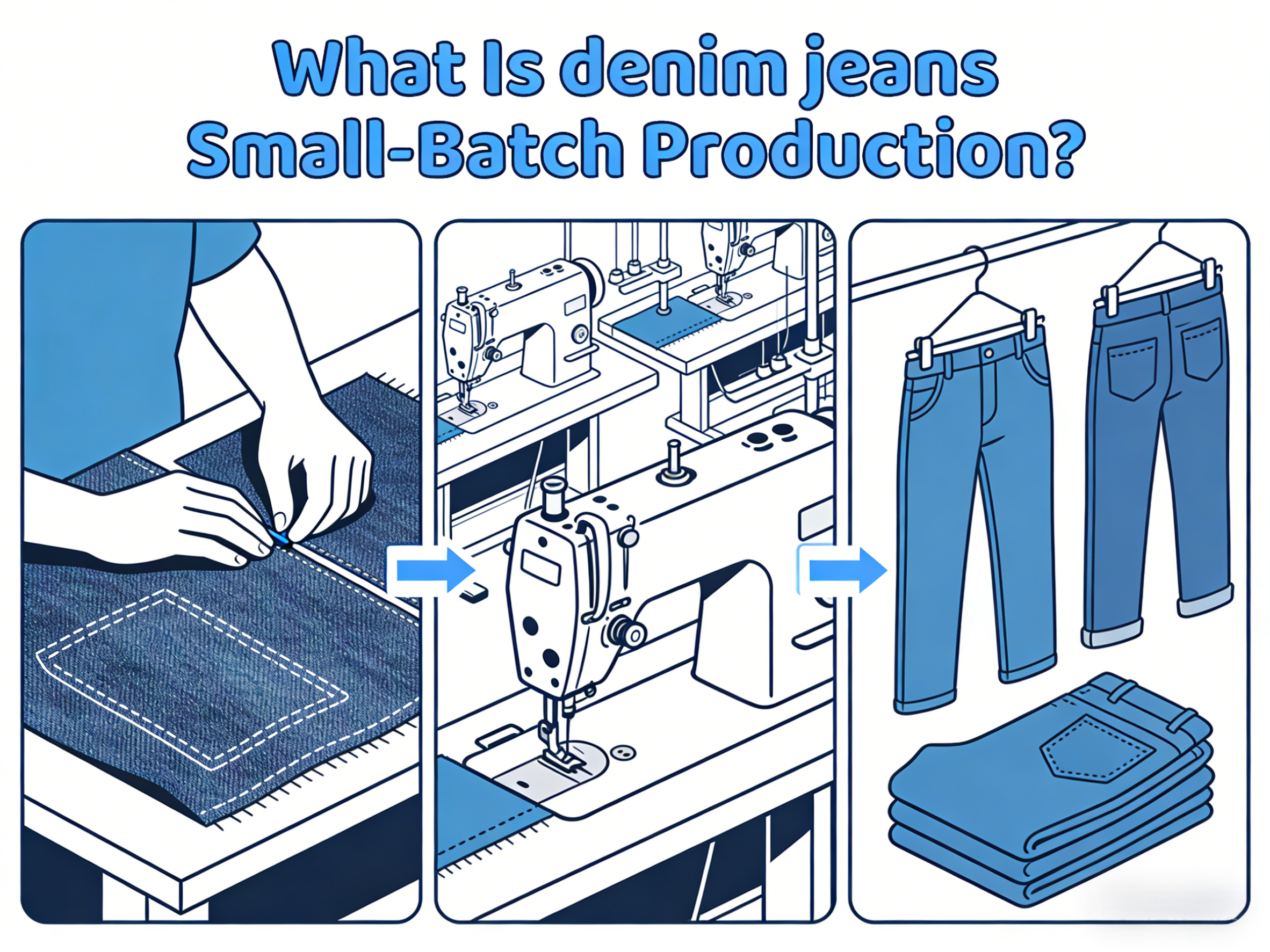

You might wonder what the small-batch revolution really means. In simple terms, small-batch production is when companies make products in limited quantities instead of huge numbers. This approach sits between mass production and custom, one-off items. Here’s what makes it stand out:

You get products made in groups or batches, not on a never-ending line.

Companies can quickly change what they make to match what customers want.

Brands can offer personalized designs and keep up with trends.

It helps reduce waste, which supports sustainability.

Small-batch production gives you more control and flexibility. You can test new ideas without risking a lot of money or ending up with piles of unsold goods.

Why the Revolution Matters for Small Businesses

The small-batch revolution has changed the game for small businesses. You can now build a brand that feels real and personal. Here’s how it impacts branding:

You can share your story and connect with customers who care about where things come from.

Your marketing can focus on the people and values behind your products.

You can engage with your local community and show your commitment to quality.

Let’s look at some trends that have shaped this movement:

Trend | Description |

|---|---|

You can offer unique products that show off your style. | |

You cut down on waste and support eco-friendly practices. | |

Engagement with Local Markets | You support your region and adapt to what local shoppers want. |

Faster Innovation | You can try new ideas and bring them to market quickly. |

Micro-exporters and B2B companies have also helped push the small-batch revolution forward. They use their agility to respond fast to changes and focus on niche products. B2B platforms make it easier to place bulk orders, which helps keep costs down and profits up.

You can see why the small-batch revolution is more than just a trend. It gives you the tools to stand out, connect with your audience, and grow your business in a smart way.

Sustainability and Small-Batch Manufacturing

Sustainable Practices in Production

You might wonder how the small-batch revolution helps the planet. When you work with small-batch factories, you only make what you need. This means you avoid piles of extra stock and cut down on waste. You also get to choose materials that are better for the environment. Many small-batch producers use recycled inputs or renewable materials. For example, some use recycled metals or plant-based fibers like bamboo.

Here’s a quick look at common sustainable practices in small-batch production:

Practice | Description |

|---|---|

Recycled Inputs | Using recycled metals, plastics, or fibers saves resources and keeps waste out of landfills. |

Renewable Materials | Choosing plant-based or fast-growing materials like bamboo helps protect natural ecosystems. |

You can see how these choices support environmental sustainability. Small-batch production also means you can test new ideas without wasting resources. You get to focus on quality, not just quantity.

Benefits for Niche and Micro Brands

If you run a niche or micro brand, you get some big advantages from sustainable practices. Boutique manufacturers and cottage industries often lead the way. They pay close attention to waste management and recycling. They also design products that last longer and can be repaired. This gives you a real edge over brands that make fast fashion or short-life products.

Key Takeaways | Implications for Boutique Manufacturers and Cottage Industries |

|---|---|

Producers must fund waste management and recycling costs. | Encourages responsible production practices among small-scale manufacturers. |

Fast fashion and short-life products will pay higher fees. | Provides a competitive advantage to sustainable small-batch producers. |

Durable, repairable, traceable designs will gain cost and compliance advantages. | Incentivizes boutique manufacturers to focus on quality and longevity in their products. |

Micro-enterprises get 12 extra months, but compliance planning must start now. | Allows cottage industries time to adapt to new regulations, promoting sustainable practices. |

Modernization in Asian manufacturing hubs also helps you. New technology like AI and IoT sensors makes it easier to control quality and reduce downtime. You can respond quickly to what your customers want. This keeps your brand fresh and helps you grow while staying true to sustainability.

Tip: Start small and focus on quality. You can build trust with your customers and show your commitment to sustainable practices.

Finding the Right Factory

Overcoming Sourcing Challenges

Finding the right small-batch factories can feel like searching for a needle in a haystack. You want a partner who understands your needs, but you might run into a few roadblocks along the way. Many small businesses and micro-exporters face similar challenges when they start looking for a factory that fits their vision.

Here’s a quick look at the most common sourcing challenges you might face:

Challenge | Description |

|---|---|

You may need to order much more material than you actually need. For example, a factory might require you to buy 300kg of fabric, even if you only need 30kg. | |

Over-Complication | Using too many different fabrics or components in one product can drive up costs, making small runs expensive. |

Ignoring Lead Times | Even small orders need time for sourcing and production. You should plan for 4–8 weeks, so you don’t get caught off guard. |

Under-Pricing | Limited edition goods cost more to make. You should price them higher to reflect their exclusivity and ethical production. |

You can tackle these challenges with a few smart strategies. Take a look at some proven ways to overcome sourcing obstacles:

Strategy | Description |

|---|---|

Look for suppliers who specialize in small-batch manufacturing and offer low minimum order quantities. Platforms like Alibaba can help you find them. | |

Establish Communication and Collaboration | Keep open lines of communication with your factory. This helps you manage the production process and solve problems quickly. |

Reduce Extensive Customization | Try to use standard materials and modular designs. This keeps costs down and makes production smoother. |

Tip: Start by building a relationship with your supplier. When you communicate clearly and set expectations early, you avoid surprises later.

Navigating Minimum Orders and Quality

Minimum order requirements can trip you up if you’re not careful. Many factories set high minimums, which can lead to extra costs and unwanted inventory. You might end up with more stock than you can sell, which ties up your cash and storage space. If you understand and manage these minimums, you can keep your business lean and profitable.

Minimum order requirements often mean higher holding costs for you.

You might struggle to meet these requirements, which can lead to overstocking.

If you plan ahead and negotiate, you can optimize your orders and improve your bottom line.

Quality control is another big concern in the small-batch revolution. You want every product to meet your standards, but small runs can make this tricky. Many small-batch factories now use AI systems to spot defects in fabric or stitching. These tools help you catch problems early and keep your quality high. However, if you rely too much on manual checks, you might miss out on the benefits of automation. Ignoring real-time data can also lead to mistakes and wasted resources.

Here are a few things to keep in mind:

AI can help you maintain quality by catching defects before products leave the factory.

Trust the data and let technology do its job. Too many manual overrides can slow you down.

Make sure your factory uses real-time data validation. This keeps your production efficient and your products consistent.

Note: Don’t be afraid to ask your factory about their quality control process. A good partner will be happy to show you how they keep standards high.

If you take the time to understand these challenges and use the right strategies, you’ll find a factory that fits your needs. The small-batch revolution gives you more options than ever, so you can build a brand that stands out.

How to Vet Small-Batch Partners

Where to Search for Factories

You have more options than ever when searching for small-batch factories. Start by thinking about what you want to make. Some countries stand out for certain products. For example:

Vietnam offers strong options for consumer goods.

India is a top choice for textiles.

Mexico gives you quick access to the U.S. market.

Portugal is known for quality in textiles, shoes, and furniture.

Online platforms and trade shows can help you connect with the right partners. These tools give you faster access to suppliers, lower your marketing costs, and offer built-in trust features like verified sellers and secure payments.

Benefit | Description |

|---|---|

Faster Access to Buyers | Online marketplaces connect buyers and sellers instantly. |

Lower Marketing Costs | Sellers gain visibility through marketplace SEO and sponsored listings. |

Built-in Trust and Verification | Platforms verify sellers and offer secure payment gateways. |

Global Reach, Local Presence | B2B marketplaces support international transactions. |

Optimized Logistics | Many platforms integrate logistics services. |

Ease of Scaling Operations | Businesses can test new categories and regions easily. |

Key Questions to Ask

Before you commit, ask the right questions. This helps you avoid surprises and find a partner who fits your needs. Here are some important things to cover:

Key Consideration | Description |

|---|---|

Small Batch Test/Prototype | Ask for a test run to check quality and responsiveness. |

Feedback Gathering | Involve your team to see how well the factory communicates. |

Collaboration Capacities | Learn about their project management and problem-solving tools. |

Location | Think about how the factory’s location affects costs and delivery. |

Equipment | Check if their machines are reliable and up to date. |

Scalability | Make sure they can handle bigger orders if you grow. |

Quality | Ask about their quality control process and request proof. |

Certifications | Look for industry certifications that show high standards. |

Compliance | Confirm they meet all rules for your market. |

Technology | See if their systems work with yours. |

Evaluating Fit and Red Flags

You want a partner you can trust. Look for clear communication and quick responses. Reliable factories often have certifications like ISO 9001 or SMETA audits. They should also show proof of compliance, such as REACH for textiles. Watch out for these warning signs:

Vague or missing headquarters details

Incomplete paperwork or missing documents

Odd or repetitive reviews

Sudden spikes in five-star ratings

Lack of transparency in communication

Tip: Always check business registration records and official documents. If something feels off, dig deeper before making a decision.

Success Stories and Tips for Small Businesses

Micro-Brand Case Studies

You can find inspiration from brands that started small and made a big impact with small-batch production. Here are a few examples:

HelloFresh works with micro-influencers to show how easy their meal kits are. This approach brings in new customers and keeps current ones engaged.

Glossier builds a strong community by teaming up with micro-influencers. They share honest reviews, which helps the brand grow among younger shoppers.

You can learn a lot from other niche businesses, too. Check out these lessons:

Business Type | Key Lesson | Source |

|---|---|---|

Unique Manufacturing | Case Studies of Successful Manufacturing Businesses Lessons Learned | |

Craft Business | Balance personal values with profitability while pursuing mastery. | |

Coffee Roasting | Ensure ambition does not compromise ethical sourcing. |

Actionable Advice for Growth

You want to grow your brand and keep things running smoothly. Here are some steps you can take:

Focus on your customers. Build strong relationships, keep them coming back, and encourage referrals.

Expand your marketing. Use social media, email, and search to get your name out there.

Drive product growth. Listen to feedback, improve quality, and look for ways to cut costs.

Invest in your team. Recognize their hard work and help them grow with your business.

Scale your systems. Automate tasks, create clear processes, and plan for bigger operations.

Dr. Amrutkar says, “Modular process design lets you change things quickly and scale up with less downtime. You can test ideas virtually and keep improving your setup.” Microfactories also help you produce on demand, lower inventory costs, and adjust quickly to market needs.

You can see how small businesses use these strategies to thrive with small-batch production. Try these tips to set your brand up for long-term success.

You now have the tools to join the small-batch revolution. This movement lets small businesses and micro-exporters try new ideas and grow in a sustainable way. When you build strong manufacturing partnerships, you gain real advantages:

You work with local partners to boost sustainability.

You build local skills and connect with regulators.

You share responsibility, which brings economic and environmental rewards.

Take the next step and put these tips into action for your brand’s future.

FAQ

What makes small-batch manufacturing different from mass production?

You get more flexibility with small-batch manufacturing. You can test unique products, adjust quickly, and reduce textile waste. Many factories focus on quality and responsible sourcing. This approach supports micro-exporters and b2b brands that want to stand out in the fashion and apparel markets.

How do I find factories that support ethical production and transparency?

Start with b2b platforms. Look for factories that share details about their processes and use eco-friendly fabrics. Radical transparency means you see every step, from sourcing to production. Ask about certifications and visit factories if you can. This helps you trust their ethical production claims.

Why do micro-exporters choose vietnam apparel manufacturing?

Vietnam apparel manufacturing offers high quality, low minimums, and strong b2b connections. You find factories skilled in fashion and apparel. They use modern technology and focus on transparency. Micro-exporters love the balance of cost, speed, and responsible sourcing. You can scale up as your consumer base grows.

How can I make sure my apparel brand uses eco-friendly and handcrafted materials?

You should ask factories about their sourcing. Many vietnam apparel manufacturing partners offer handcrafted options and eco-friendly materials. Check for certifications and request samples. This ensures your apparel line meets consumer demand for unique products and supports ethical production.

What are the main benefits of working with niche factories for fashion brands?

Niche factories give you more control over quality and design. You can create unique products, use eco-friendly materials, and reduce waste. These factories often support micro-exporters and b2b brands. You get better transparency, faster production, and a stronger connection with your consumer.

Tip: Always ask for a sample batch before full production. This helps you check quality and transparency.

Benefit | Why It Matters for You |

|---|---|

Quality | You deliver better apparel and fashion |

Transparency | You build consumer trust |

Flexibility | You adapt to trends fast |

Responsible Sourcing | You support ethical production |

Lower Waste | You help the environment |