You want to launch your startup with standout denim products, but finding small-batch denim order solutions can feel overwhelming. You need low MOQs to test the market, flexibility for your designs, and top-notch quality. Online platforms like Maker’s Row and Alibaba help you connect with manufacturers, while trade shows such as Texworld USA and Denim Première Vision open doors to global sourcing and networking. Many startups also seek sustainability and premium fabrics to build a trusted brand.

Type | Name | Region |

|---|---|---|

Trade Show | Denim Première Vision | Global |

Trade Show | Canton Fair | China |

Trade Show | Texworld USA | USA |

Online Platform | Maker’s Row | U.S. |

Online Platform | Alibaba | Asia |

Online Platform | Intertex | Latin America |

Key Takeaways

Define your brand vision and product goals. This clarity helps guide your decisions and keeps you focused.

Start with small order quantities to test the market. This approach reduces financial risk and allows for quick adjustments.

Utilize online platforms and trade shows to connect with manufacturers. These resources provide valuable networking opportunities and options.

Request samples to assess quality before committing. Checking for defects ensures you maintain high standards for your products.

Build strong relationships with suppliers. Good communication and trust lead to better results and smoother production processes.

Define Your Denim Product Needs

Clarify Brand Vision and Product Goals

You want your denim brand to stand out. Start by asking yourself what story you want your brand to tell. Do you want to focus on sustainability, bold designs, or classic fits? Your vision will shape every decision you make, from fabric selection to marketing. Write down your goals. Maybe you want to launch with three styles or test a limited run. Clear goals help you stay focused when you start talking to manufacturers about small batch denim production.

Set Order Quantities and Budget

Now, let’s talk numbers. You don’t need to order thousands of pairs to get started. Many startups choose small batches to test the market and reduce risk. For your first collection, fabric costs usually range from $2,000 to $7,000. Production costs for small batch denim production often fall between $18 and $45 per pair. You’ll also need to budget for product development, which can run from $2,550 to $9,800. Make a simple table to track your costs and keep your spending on target.

Cost Type | Typical Range |

|---|---|

Fabric | $2,000 – $7,000 |

Production (per pair) | $18 – $45 |

Product Development | $2,550 – $9,800 |

Validate Your Denim Product Idea

Before you commit to large batches, test your concept with small batches. Share samples with friends, family, or potential customers. Gather feedback on fit, style, and comfort. You can use online surveys or pop-up events to see what people love. This step helps you avoid costly mistakes and gives you confidence before you scale up. Remember, small batches let you pivot quickly if you need to tweak your designs or try something new.

Research Small-Batch Denim Order Solutions

Online Directories and Platforms

You have more options than ever when it comes to finding small-batch denim order solutions. Online directories and platforms make it easy to connect with manufacturers and suppliers who understand the needs of startups. These resources help you compare options, check reviews, and find the right fit for your brand.

Maker’s Row and Alibaba are popular starting points for sourcing denim. You can browse profiles, see past projects, and even message manufacturers directly.

Wholesale Fashion Trends stands out for its boutique-friendly minimum order requirements, making it ideal for small-batch denim order solutions.

FashionGo offers a huge variety, but you might feel overwhelmed by the choices. Take your time and use filters to narrow down your search.

LA Showroom has higher minimum order requirements, so it works best if you plan to scale up soon.

Faire gives you unique net 60 payment terms, which can help reduce upfront costs and ease cash flow.

Here’s a quick look at how some top platforms compare:

Platform | Minimum Order Quantity Description |

|---|---|

Wholesale Fashion Trends | Boutique-friendly minimum order requirements |

FashionGo | Offers a wide variety, but may be overwhelming |

LA Showroom | Higher minimum order requirements compared to others |

Faire | Unique net 60 payment terms, reducing upfront costs |

When you use these platforms, always check the supplier’s reputation. Look for feedback from previous customers. This step helps you avoid surprises and ensures you get quality denim for your collection.

Trade Shows and Networking

Trade shows are a goldmine for anyone searching for small-batch denim order solutions. You get to meet manufacturers face-to-face, see fabric samples, and build real relationships. Events like Texworld, Magic, and Denim Première Vision bring together the best in the industry. You can ask questions, compare suppliers, and even negotiate better terms on the spot.

Tip: Networking at trade shows often leads to partnerships that last for years. Many industry leaders say that collaboration is the secret to success in the denim world.

Kingpins, for example, has teamed up with Messe Frankfurt to create even better trade show experiences. Seminars like Kingpins Denim Talks at Texworld LA bring experts together and show how important networking is for building your brand. These events help you connect with suppliers who offer low MOQs and premium fabric sourcing, both of which are crucial for startups.

Leveraging Online Communities and Reviews

Don’t underestimate the power of online communities and reviews when searching for small-batch denim order solutions. Forums, Facebook groups, and LinkedIn communities are full of people who have been in your shoes. They share honest feedback about manufacturers and suppliers, so you can learn from their experiences.

Join groups focused on denim production or small-batch manufacturing.

Ask questions about sourcing, quality, and customer service.

Read reviews and look for patterns—if several people mention the same issue, take note.

You can also find recommendations for suppliers who specialize in small-batch orders and premium fabrics. This feedback helps you avoid common pitfalls and find partners who care about quality as much as you do.

By using online directories, attending trade shows, and tapping into online communities, you set yourself up for success. You’ll find small-batch denim order solutions that match your vision, budget, and growth plans.

Evaluate and Select Manufacturers

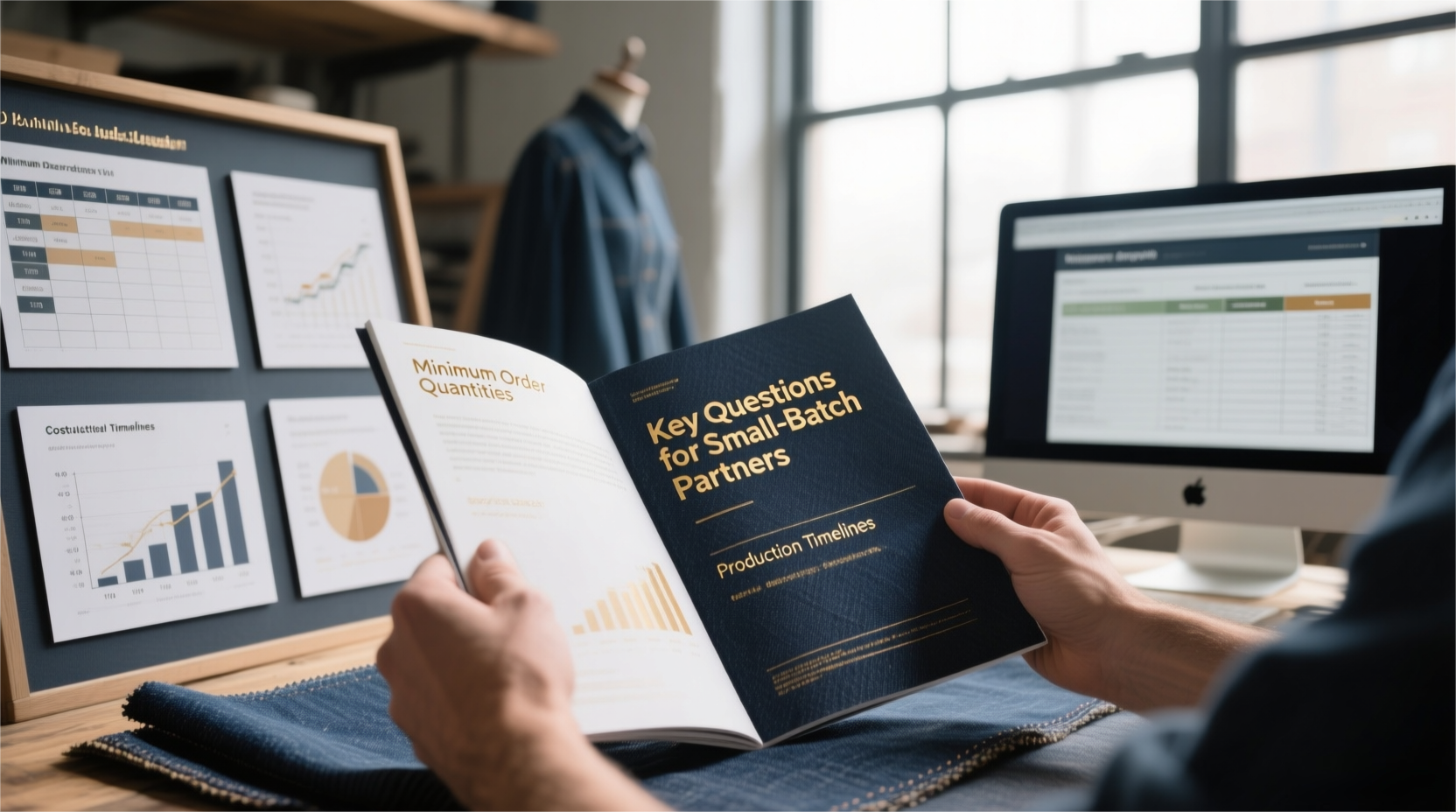

Key Questions for Small-Batch Partners

When you talk to potential manufacturers, you want to make sure they fit your needs as a startup. Ask about their minimum order quantities, production timelines, and experience with custom manufacturing. Find out if they have worked with other clothing manufacturers for startups or apparel manufacturers for startups. You should also ask about their sourcing process and how they handle quality control. Reliable suppliers will answer your questions clearly and provide references.

Here’s a quick table to help you compare important criteria:

Criteria | Description |

|---|---|

Quality Assurance and Certifications | Look for certifications like ISO 9001 or WRAP, and request samples to ensure quality consistency. |

Production Capacity and MOQ Flexibility | Ensure the factory can meet your production needs and has options for scaling. |

Cost-Effectiveness and Pricing Structure | Balance quality with affordability; analyze costs to maintain profit margins. |

Ethical Practices and Sustainability | Choose factories with Fair Trade or B Corp certifications and eco-friendly materials. |

Communication and Reliability | Prioritize responsive factories; check reviews to confirm reliability and timely problem-solving. |

Check Certifications and Sustainability

Certifications show that manufacturers care about quality and sustainability. Ask your sourcing partner about certifications like GOTS, Bluesign, or OEKO-TEX®: STANDARD 100. These prove that the denim meets high standards for safety and environmental impact. Some suppliers also hold MADE IN GREEN or Global Recycled Standard certifications, which means they use recycled materials and follow strict sustainability rules. If you want a high-quality denim collection, choose vetted clothing manufacturers who can show these credentials.

Certification Name | Purpose | Key Benefits |

|---|---|---|

GOTS | Ensures organic cotton and ethical production processes | Monitors 1.4 million workers in 4,600 factories, ensuring ethical and sustainable practices. |

Bluesign Standard | Focuses on safe working conditions and ecological footprint | Ensures high safety standards for workers and minimizes environmental impact. |

OEKO-TEX®: STANDARD 100 | Ensures textiles are free from harmful substances | Guarantees consumer safety by monitoring dyes and chemicals used in textiles. |

MADE IN GREEN | Addresses environmental sustainability and social responsibility | Allows traceability of products to verify compliance with sustainability standards. |

Global Recycled Standard (GRS) | Tracks recycled materials in the supply chain | Provides assurance that products contain recycled materials. |

Request Samples and Assess Quality

You should always request samples before making a final decision. Most domestic manufacturing partners can deliver samples in 1 to 2 weeks. Use this time to check for quality control issues. Look for even stitching, smooth seams, and consistent color. Watch out for common problems like uneven washing, finishing residues, or misaligned pockets. Here’s a table of issues to check:

Defect Type | Description | Impact on Product Appearance |

|---|---|---|

Uneven Washing / Abrasion Marks | Inconsistent results from washing processes. | Inconsistent product appearance within a batch. |

Finishing Residues | Lingering chemical smells or stains from incomplete rinsing. | Can cause skin irritation and indicates poor practices. |

Skipped Stitches / Broken Stitches | Gaps in the sewing line due to needle failure or broken thread. | Weakens the seam, leading to garment failure. |

Seam Puckering | Rippling along a seam line caused by uneven fabric feeding. | Aesthetic defect, may affect fit if severe. |

Misaligned Pockets | Crooked or unevenly spaced pockets and components. | Major aesthetic flaw indicating careless construction. |

Incorrect Stitch Count | Low or inconsistent stitches per inch. | Results in weaker seams and unprofessional appearance. |

Tip: If you spot any of these issues, ask your suppliers how they plan to fix them. Good quality control means fewer headaches down the road.

Negotiate Terms and Confirm Capabilities

When you negotiate with manufacturers, start by understanding their cost structure. Ask for a breakdown of production costs, including installation, training, and maintenance if you’re considering local manufacturing. If you can increase your order size, you might get better pricing. Building a long-term relationship with your sourcing partner can also lead to more favorable terms. Many manufacturers show their capabilities by providing physical samples, offering on-site demonstrations, or running pilot installations. Domestic manufacturing partners often highlight improvements like faster cycle times and higher throughput, which help you scale up smoothly.

If you follow these steps, you’ll find apparel manufacturers for startups who deliver consistent quality and support your growth. The right suppliers make sourcing and custom manufacturing easier, so you can focus on building your brand.

Recommended Clothing Manufacturers in the USA and Beyond

Clothing Manufacturers in the USA

You have great options when you look for clothing manufacturers in the usa that focus on small-batch denim. Baagh Enterprises stands out for startups. They offer everything from pattern making to customizations. You can pick your denim wash and fit, so your collection feels unique. Many made in usa manufacturers keep their minimum order quantities low—sometimes as few as 10 pieces per style. Most clothing manufacturers in the usa set MOQs between 50 and 500 units, but you can often negotiate. This flexibility helps you test the market without a huge investment. American-made denim also means you get top quality and craftsmanship. Many made in usa factories use small-batch production to boost quality and support sustainable practices. You can build your brand with confidence when you choose these partners.

Europe-Based Denim Manufacturers

Europe offers some excellent choices for sustainable and small-batch denim. You can find clothing manufacturers in the usa, but Europe brings its own strengths. Many European manufacturers focus on eco-friendly materials and ethical sourcing. Here are two top picks:

Manufacturer | Location | MOQ (pieces) | Specialty |

|---|---|---|---|

Zeria Textile | Porto, Portugal | 30-50 | Sustainable and organic clothing |

Prood | Barcelona, Spain | 75-200 | Sustainable streetwear and casual fashion |

Both Zeria Textile and Prood keep their MOQs low, so you can start small. They also use sustainable fabrics, which helps your brand stand out in a crowded market.

Asia-Based Denim Manufacturers

Asia remains a powerhouse for denim production. You get a wide range of options, from quick-turnaround custom jeans to high-volume runs. Many Asian manufacturers now offer low MOQs, starting at 100 pieces per design. Some, like DiZNEWJeans, go as low as 30 pieces. You can find made in usa quality and innovation in many Asian factories. Here’s a quick look at some leading names:

Manufacturer Name | Location | MOQ | Main Products |

|---|---|---|---|

DiZNEWJeans | Guangzhou, Guangdong Province | 30 pieces | Fashion-forward, quick-turnaround custom jeans |

Foshan Fly Jeans Garment Co., Ltd. | Foshan, Guangdong Province | 100-300 pieces | Women’s, men’s, kids’ denim jeans & products |

Maya Garment Co., Ltd. | Guangzhou, Guangdong Province | 100 pieces | High-end jeans |

Qingdao Ruian Industry and Trade Co., Ltd. | Qingdao, Shandong Province | No MOQ | Jeans (limited variety) |

You can see that Asian manufacturers give you flexibility and speed. Many now focus on sustainable sourcing and premium quality, making them a smart choice for startups.

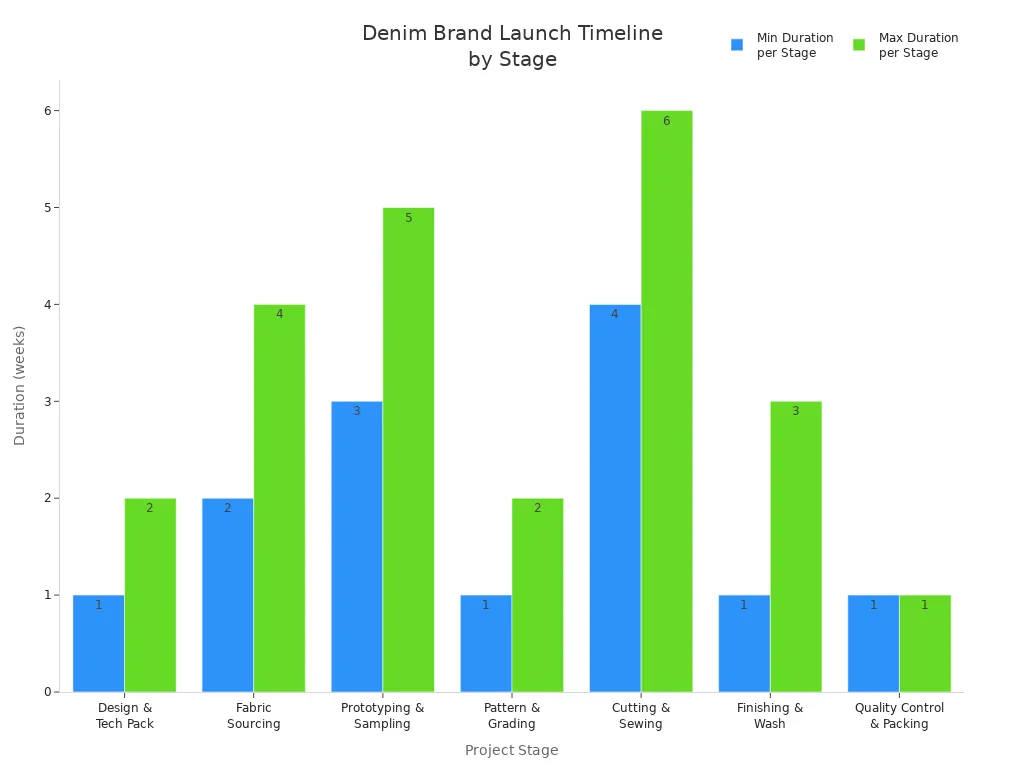

You can launch your denim brand by following a clear process. Start by sharing your designs, approve samples, confirm your order, and keep quality checks in place. Here’s a quick look at the steps:

Share your design ideas.

Approve the prototype.

Confirm order size and timing.

Oversee production and quality.

Arrange shipping.

Feature | Why It Matters |

|---|---|

Low MOQ | Reduces financial risk |

Custom Wash & Fit Options | Makes your brand unique |

Quality Denim Fabric | Keeps customers happy |

In-House Sampling | Speeds up design approval |

Private Label Service | Builds your brand identity |

Remember, due diligence helps you spot red flags and build trust. Strong relationships with your partners lead to better results. Use sustainable methods like waterless dyeing and eco-friendly machines to stand out. Take action now—your denim brand’s success starts with the first step!

FAQ

What is a typical minimum order quantity (MOQ) for small-batch denim?

You can find MOQs as low as 10 to 100 pieces per style. Some manufacturers offer even lower MOQs for sample runs. Always ask about flexibility before you commit.

How long does small-batch denim production take?

Production usually takes 4 to 8 weeks after you approve your samples. Timelines depend on the factory’s schedule and your order size. Ask for updates to stay on track.

Can I customize denim washes and fits in small batches?

Yes! Many manufacturers let you choose custom washes, fits, and finishes. You can create a unique look for your brand, even with small orders.

Are there sustainable options for small-batch denim?

Absolutely. Many suppliers now offer organic cotton, recycled materials, and water-saving processes. Look for certifications like GOTS or Bluesign to make your collection eco-friendly.

Is small-batch denim a good choice for startups?

Small-batch denim lets you test the market, control costs, and adjust your designs quickly. This approach helps startups reduce risk and build a strong brand foundation.