You can expect custom denim production lead times to range from 8 to 12 weeks for most orders. Small-batch or Fast-Track Denim Production Timelines may reduce this period, while large or complex jeans orders often take longer. Understanding each step and its duration helps you plan ahead and avoid delays. The table below shows typical lead times for different denim types:

Type of Denim | Average Lead Time |

|---|---|

Raw Denim | 8–12 weeks |

Selvedge Denim | 12–16 weeks |

Pre-Washed Denim | 12–18 weeks |

Seasonal Delays | Additional 2–4 weeks |

You should always consider your own brand’s needs when planning for custom denim projects.

Key Takeaways

Custom denim production typically takes 8 to 12 weeks. Plan ahead to avoid delays.

Each production phase has its own duration. Understanding these helps you manage your timeline effectively.

Choose your fabric wisely. Heavier fabrics take longer to source and process.

Build buffer periods into your schedule. Extra time helps manage unexpected delays.

Select the right manufacturing partner. Strong relationships can improve pricing and lead times.

Custom Denim Production Timeline Overview

Typical Lead Times

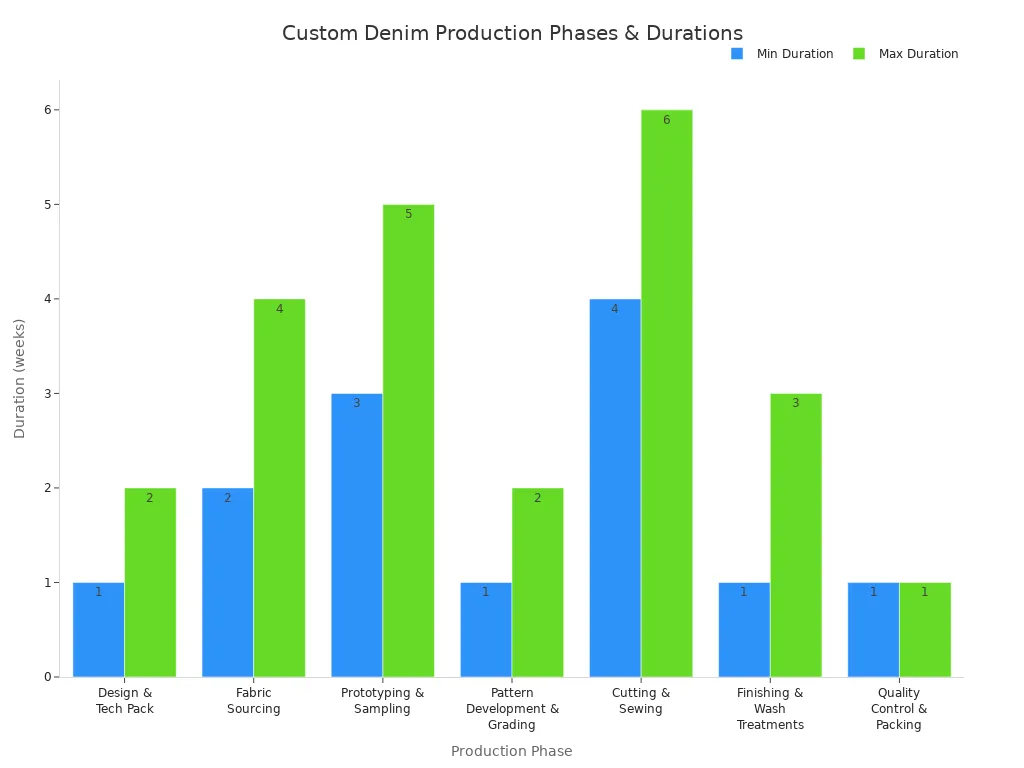

You need to understand how each phase fits into your production calendar. Custom denim projects follow a fashion production calendar that includes several steps. Each step has its own duration and risks if rushed. The table below shows the main phases and how long each usually takes:

Phase | Typical Duration | Risks if Rushed |

|---|---|---|

Design & Tech Pack | 1–2 weeks | Miscommunications, re-sampling |

Fabric Sourcing | 2–4 weeks | Wrong weight, delayed start |

Prototyping & Sampling | 3–5 weeks | Poor fit, styling inconsistencies |

Pattern Development & Grading | 1–2 weeks | Sizing errors across range |

Cutting & Sewing | 4–6 weeks | Production delays, waste |

Finishing & Wash Treatments | 1–3 weeks | Color inconsistency, damage |

Quality Control & Packing | 1 week | Returns, brand reputation risk |

You can see that the production calendar for denim covers several weeks. If you want to produce jeans quickly, you must plan each phase carefully. The fashion production calendar helps you track progress and avoid delays.

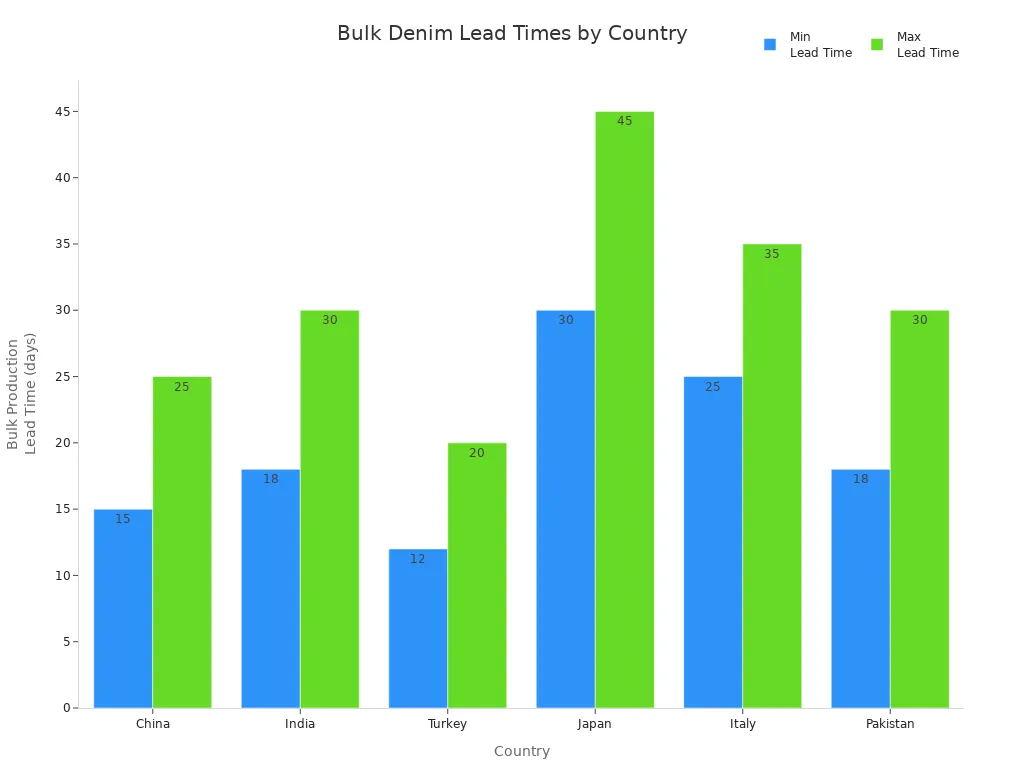

Lead times also depend on where you manufacture your denim. The table below compares sample and bulk production calendar durations in different countries:

Country | MOQ (Standard Denim) | Sample Lead Time | Bulk Production Lead Time |

|---|---|---|---|

China | 300–500 meters | 5–7 business days | 15–25 business days |

India | 200–400 meters | 6–8 business days | 18–30 business days |

Turkey | 200–300 meters | 5–7 business days | 12–20 business days |

Japan | 100–300 meters | 10–15 business days | 30–45 business days |

Italy | 300–600 meters | 7–10 business days | 25–35 business days |

Pakistan | 400–800 meters | 5–8 business days | 18–30 business days |

If you work with a factory in Turkey, you may finish bulk denim production in as little as 12 business days. Japan usually takes longer, so you must adjust your production calendar if you want Japanese denim.

Established brands and startups experience different lead times. The table below shows how quickly some brands complete their denim production calendar:

Brand | Lead Time |

|---|---|

Bless Denim | Fast (2-4 weeks) |

Levi’s | Slow (4-6 weeks) |

Diesel | Slow (4-6 weeks) |

True Religion | Slow (4-6 weeks) |

G-Star RAW | Moderate (3-5 weeks) |

If you run a startup, you may finish your production calendar faster than a large brand. You can use specialized production lines to speed up your denim orders.

Key Influencing Factors

Many factors shape your denim production calendar. You need to consider these when planning your fashion production calendar:

Fabric Choice: Heavier selvedge denim with custom hardware takes longer to source and finish. Simpler blends move faster through the production calendar.

Design Complexity: More pattern pieces and special finishes add time to your production calendar. Simple jeans designs reduce delays.

Order Volume: Large orders may streamline your production calendar, but they can also complicate scheduling.

Factory Location: Domestic factories shorten your production calendar, but they cost more. Overseas options extend your production calendar due to shipping.

Compliance Requirements: Meeting regulations adds steps to your production calendar.

The table below summarizes these factors:

Factor | Description |

|---|---|

Fabric Choice | Heavier selvedge denim with custom hardware increases costs and lead times; simpler blends reduce them. |

Design Complexity | More pattern pieces and special finishes increase labor and time required for production. |

Order Volume | Larger orders can streamline production but may also complicate scheduling. |

Factory Location | Domestic production reduces shipping time but is more expensive; overseas options take longer. |

Compliance Requirements | Meeting specific regulations can add time to the production process. |

You also need to think about minimum order quantities (MOQs) and sampling. Here are some key points:

Low MOQ gives you flexibility. You can produce custom denim from as few as 30 pieces, which lowers your upfront costs.

Rapid sample-to-bulk turnaround helps you move quickly through your production calendar. Specialized lines let you go from design to finished denim in weeks.

Accelerated cash-flow cycles mean you get your denim faster, sell it sooner, and see returns on investment earlier.

If your denim design is complex or you have many SKUs, your production calendar will stretch. The table below shows how each stage affects your timeline:

Stage | Timeline |

|---|---|

Fabric and trims sourcing | 10–15 days |

Sampling | 7–10 days |

Bulk manufacturing | 25–40 days |

Final inspection and shipping | 7 days |

Tip: You should always build extra time into your production calendar for revisions and unexpected delays. This keeps your denim project on track and helps you deliver on time.

You can manage your fashion production calendar by tracking each phase and adjusting for key factors. This helps you avoid delays and keeps your denim orders moving smoothly.

Design & Tech Pack

Design Brief & Approval

You start your custom denim journey by creating a clear design brief. This document outlines your vision for the jeans, including style, fit, washes, and special details. You describe your target customer and the purpose of the collection. You also specify the number of styles and any unique features, such as embroidery or custom hardware.

You share your design brief with your production partner. They review your ideas and ask questions to clarify details. You approve the final version before moving forward. This step sets the foundation for the entire project. If you skip details or rush approval, you risk miscommunication and costly changes later.

Tip: You should include reference images, sketches, and notes about your brand’s identity. These visuals help your factory understand your expectations.

Tech Pack Preparation

Once you approve the design brief, you prepare the tech pack. This document acts as the blueprint for your denim. It includes every measurement, material, trim, and construction detail. You list the stitching type, pocket placement, and wash instructions. You also add technical drawings and size charts.

A complete tech pack speeds up production and reduces errors. Factories rely on this information to plan resources and avoid guesswork. You minimize revisions and resampling, which often delay your timeline. You also ensure fit consistency and prevent costly returns.

A complete tech pack minimizes revisions and resampling, which can delay production.

It provides clear specifications that help factories calculate necessary resources accurately, reducing guesswork and potential delays.

By defining every measurement point, it ensures fit consistency, which prevents production failures and returns.

Tech Pack Essentials | Why It Matters |

|---|---|

Measurements | Ensures accurate fit |

Materials & Trims | Guides sourcing and costing |

Construction Details | Prevents miscommunication |

Wash Instructions | Achieves desired finish |

You should double-check every detail before sending your tech pack. This step saves time and money throughout the denim production process.

Fabric Sourcing & MOQ

Sourcing Options

You have many choices when it comes to sourcing fabric for your denim project. You can select from local mills, international suppliers, or work directly with a premium denim manufacturer. Each option offers different benefits. Local mills often provide faster turnaround and easier communication. International suppliers, such as a jeans manufacturer in china, may offer a wider range of fabrics and lower costs. If you want to focus on sustainable manufacturing, look for mills that use eco-friendly processes and recycled fibers.

When you choose your fabric, consider the weight, weave, and finish. Heavier fabrics usually take longer to source and process. Custom developments under 200 meters often require extra sampling and setup charges. You should also check if your supplier can meet your minimum order quantity (MOQ) needs. Standard factory MOQs range from 30 to 50 units per style, but some mills require fabric MOQs of 300–500 meters.

Tip: Ask your supplier about lead times for both in-stock and custom fabrics. This helps you plan your premium jeans production schedule more accurately.

MOQ Impact on Timelines

MOQs play a big role in your production timeline and costs. If you order below the standard MOQ, you may face higher prices and longer waits. MOQs of 300–500 meters can add 15–25% to the base price. Larger orders often benefit from tiered pricing, such as a 5% discount at 100 pieces and a 10% discount at 300 pieces. When you order more, you spread setup costs across more units, which lowers your per-unit price.

Here is a quick overview of how different factors affect your costs and lead times:

Factor | Impact on Costs and Lead Times |

|---|---|

Fabric choice | Heavier fabrics increase costs and lead times. |

Complexity of design | More complex designs lead to higher costs and longer lead times. |

Order volume | Larger orders reduce per-unit costs and setup fees. |

Factory location | Proximity can affect lead times and shipping costs. |

Compliance requirements | Additional compliance can increase lead times and costs. |

You should always balance your order size with your budget and timeline. Planning your fabric sourcing early helps you avoid delays and keeps your denim project on track.

Sampling & Prototyping

Sample Development

You move into the sampling stage after you finish your tech pack and source your fabric. This step lets you see your design come to life for the first time. You work closely with your manufacturer to create a physical sample of your denim product. The sample shows the fit, construction, and finishing details. You use it to check if the design matches your vision.

The average duration for sample development in custom denim manufacturing is:

You should expect this process to take about two to three weeks. During this time, your factory cuts, sews, and finishes the sample using your chosen materials and trims. You can request photos or videos of the process to stay updated. If you want to speed up this stage, provide clear feedback and respond quickly to questions from your production partner.

Tip: Always review your sample in person if possible. Photos may not show color, texture, or fit accurately.

Revision Cycles

You may need to go through several revision cycles before you approve the final sample. Each cycle gives you a chance to adjust measurements, change details, or improve the fit. You should give clear, specific feedback after each round. This helps your manufacturer understand what you want and reduces the number of revisions needed.

Most brands go through two or three sample rounds. Each revision can add 7 to 10 days to your timeline. You should plan for these extra days when you set your production schedule. Fast communication and detailed notes help you move through revision cycles quickly.

You set yourself up for a smooth bulk production run when you take the time to perfect your sample. This step ensures your denim meets your quality standards and matches your brand’s style.

Pattern & Grading

Pattern Creation

You begin the next stage of custom denim production by creating patterns for your designs. A pattern acts as the template for each piece of your jeans. You work with a pattern maker who translates your tech pack into physical or digital shapes. These shapes guide the cutting and sewing process. You must ensure every detail matches your design brief, from pocket placement to seam allowances.

Pattern creation usually takes one to two weeks. You review the first draft and check for accuracy. If you spot errors, you request adjustments before moving forward. A precise pattern helps you avoid costly mistakes during bulk production. You should always double-check measurements and construction details at this stage.

Tip: Ask your pattern maker to provide digital files. Digital patterns make it easier to share updates and speed up communication with your manufacturer.

Grading Process

Once you approve the base pattern, you move on to grading. Grading means adjusting the pattern for different sizes. You want your denim to fit a range of body types, so grading is essential. The process involves analyzing the base pattern, developing grading rules, and using digital tools to create size variations.

Grading impacts your production timeline in several ways. You save time and money by using digital grading instead of making separate patterns for each size. Quality checks ensure every size fits well and meets your standards. The table below shows how each grading step affects your timeline:

Step | Impact on Production Timeline |

|---|---|

Analysis | Ensures designs fit various body types |

Rule Development | Establishes grading standards for consistency |

Digital Grading | Streamlines the grading process for efficiency |

Quality Checks | Maintains accuracy and fit across sizes |

Format Preparation | Prepares patterns for production, reducing delays |

Overall Efficiency | Leads to reduced time and costs compared to individual patterns |

You should prepare all graded patterns before bulk production begins. This step keeps your denim project on schedule and helps you deliver consistent quality across every size.

Cutting & Sewing

Production Scheduling

You enter the cutting and sewing phase after finalizing patterns and grading. This stage transforms your denim designs into actual garments. Production scheduling plays a key role in keeping your project on track. You must consider several factors before starting the process. The location of your manufacturing facility, labor practices, and shipping costs all influence your timeline and budget.

Here is a table that highlights the main factors affecting production scheduling in denim manufacturing:

Factor | Description |

|---|---|

Production Costs | Asian factories offer lower costs per unit due to efficient production methods and lower labor costs. |

Shipping Costs | Shipping costs and tariffs can significantly affect the total price of denim products. |

Hidden Expenses | Unexpected costs such as quality control checks and currency exchange rates can arise when manufacturing overseas. |

Labor Practices | Ethical labor practices are crucial for brand reputation and compliance with safety regulations. |

Modern consumers prefer ethically produced denim that minimizes environmental impact. Ethical compliance is becoming a significant factor in production scheduling. You must adapt to these trends to meet customer expectations and maintain your brand’s reputation.

Note: The globalization of denim value chains allows you to achieve cost savings and reach new markets. Sourcing raw materials and production from low-cost regions helps you lower operational costs and meet global demand.

Batch Processing

Batch processing helps you optimize production runs and improve efficiency. You group similar denim styles and sizes together, which reduces setup times and allows for simultaneous production of multiple units. This method leads to cost savings and quicker turnaround times.

Batch processing optimizes production runs, enhancing efficiency.

It reduces setup times, allowing for simultaneous production of multiple units.

This method can lead to cost savings and quicker turnaround times.

However, you need careful planning and coordination to ensure all components are ready before starting batch processing. This may require extra time at the beginning, but it pays off with smoother operations and faster delivery.

Tip: You should work closely with your manufacturer to organize batches based on style, size, and wash treatments. This approach helps you avoid bottlenecks and keeps your denim production moving forward.

Finishing & Wash

Wash Treatments

You reach the wash treatments stage after sewing and assembling your jeans. This step gives your denim its final look and feel. Wash treatments can change the color, texture, and softness of the fabric. You can choose from light, standard, or heavy washes. Each type creates a different effect and takes a different amount of time.

Here is a table that shows how long each wash treatment usually takes:

Wash Type | Duration |

|---|---|

Light Normal | 5 minutes |

Standard Normal | 15 minutes |

Heavy Normal | 30 minutes |

Light washes use less water and chemicals. They keep the fabric close to its original state. Standard washes create a balanced look with some fading and softness. Heavy washes take the longest. They give the jeans a worn-in appearance and a softer feel. You should choose the wash type that matches your brand’s style and your customer’s preferences.

Tip: Always test your chosen wash on a sample before starting bulk production. This helps you avoid surprises and ensures you get the results you want.

Final Finishing

After washing, your jeans go through final finishing steps. These steps include pressing, trimming loose threads, and attaching any last details like buttons or labels. You also inspect each pair to make sure they meet your quality standards. Final finishing gives your denim a polished look and prepares it for packing.

You should pay close attention during this stage. Small mistakes can affect the overall quality of your product. Good finishing helps your jeans stand out and builds trust with your customers. When you follow a careful process, you deliver denim that looks great and lasts longer.

Quality Control & Packing

Inspection Steps

You need to follow a strict inspection process to make sure your denim meets high standards. Quality control starts with fabric inspection. You check for weaving defects, shade differences, and stains. You also test the fabric’s weight and color fastness. Next, you inspect trims and accessories. You look at zippers, buttons, and labels to confirm they work well and match your approved samples.

Cutting inspection comes next. You compare cut panels to the pattern and check for the right shape and size. Sewing quality checks help you spot problems with stitching, thread color, and seam strength. During sewing, you also do in-process inspections. These random checks help you catch errors early and keep measurements on track.

After sewing, you review the washing and finishing. You make sure the wash effect looks even and the denim feels soft. You measure key points and compare them to your size chart. You classify any defects as major, minor, or critical. The final inspection uses the AQL standard. You check the packed jeans, labels, and cartons before shipping.

Inspection Step | Description |

|---|---|

Fabric Inspection | Check for weaving defects, shade variation, slubs, stains, or holes. Verify GSM, shrinkage, and color fastness. |

Trims and Accessories Check | Inspect zippers, buttons, rivets, and labels for functionality and durability. Ensure trims match approved samples. |

Cutting Inspection | Verify cut panels against pattern for correct shape, size, and grain line. Ensure no fabric defects are visible. |

Sewing Quality Check | Inspect stitching for uniformity, tension balance, and seam strength. Confirm correct thread color and stitch density. |

In-Process Inspection | Randomly inspect during sewing to catch errors early. Ensure compliance with measurement charts. |

Washing and Finishing Check | Verify wash effects for consistency. Check for shade variation and ensure softness and safety standards. |

Final Measurement Check | Measure key dimensions and compare with buyer’s size chart. |

Defects Classification | Identify and classify defects as Major, Minor, or Critical. |

Final Inspection | Inspect packed jeans using AQL standard. Check packaging, labeling, and carton condition. |

Tip: Careful inspection at every step helps you avoid costly returns and keeps your customers happy.

Packing & Shipping

After inspection, you move to packing and shipping. You pack each pair of jeans with care to protect them during transport. You use strong cartons and clear labels to make sure the right products reach the right place. For sample orders, packing and shipping usually take 7 to 10 days. Bulk production orders need more time, often 20 to 35 days.

Order Type | Lead Time |

|---|---|

Sample Orders | 7-10 days |

Bulk Production | 20-35 days |

You should plan for these lead times when you schedule your denim launch. Good packing and shipping practices help you deliver products on time and in perfect condition.

Fast-Track Denim Production Timelines

You may need to speed up your custom denim project to meet tight deadlines or launch dates. Fast-track denim production timelines help you deliver products quickly without sacrificing quality. You can use special strategies to move through each phase faster and avoid common bottlenecks.

Expedited Sampling

You can accelerate the sampling process by planning for multiple feedback loops with your suppliers. You should expect at least two or three sample iterations, since your first sample often needs changes. You can save time by giving clear feedback and staying flexible with your calendar. Treat your timeline as a living document and adjust as needed.

You can use project management tools to visualize and track progress in real time. These tools help you spot delays early and keep everyone on the same page. You should also integrate quality checkpoints throughout the sampling phase. Catching mistakes early prevents costly errors later.

Key strategies for expedited sampling:

Plan for several sample iterations and quick approvals.

Use project management tools for real-time tracking.

Stay flexible and adjust your timeline as needed.

Add quality checkpoints to catch mistakes early.

Delays in sample approval can push back your planned cut date. This affects the start of bulk production and may require overtime or extra resources.

Shortened Bulk Production

You can shorten bulk production by preparing all materials and patterns before the cut date. Fast-track denim production timelines rely on tight scheduling and strong communication with your factory. You should group similar styles and sizes for batch processing. This method reduces setup times and speeds up production.

You must watch for delays in finishing. Rushed finishing can lead to defects and lower quality. You should keep quality control steps in place, even when working quickly. Fast-track denim production timelines also depend on quick shipment. If you approve samples on time, you avoid missed delivery dates and unhappy customers.

Fast-Track Step | Benefit |

|---|---|

Early material prep | Faster production start |

Batch processing | Reduced setup time |

Real-time tracking | Immediate problem solving |

On-time sample approval | Timely shipment |

You can use fast-track denim production timelines to launch your jeans collection quickly and stay ahead in the market.

Tips for Managing Custom Denim Lead Times

Planning & Communication

You can reduce delays in custom jeans production by focusing on strong planning and clear communication. Start with a structured production calendar. This calendar acts as your roadmap, helping you track each step and avoid last-minute problems. Use dynamic resource allocation tools, such as AI, to analyze production data and create optimized schedules. These tools help you spot bottlenecks and keep your jeans project moving smoothly. Communicate your expectations with your factory and suppliers. Share updates often and respond quickly to questions. When you use real-time quality control and automated processes, you help small factories deliver high-quality jeans on time.

Tip: Set clear deadlines for each phase and confirm them with your team. This keeps everyone focused and prevents confusion.

Buffer Periods

You should always build buffer periods into your jeans production timeline. If your factory quotes four weeks for production, schedule five or six weeks instead. Add a contingency week after major phases like sampling. This extra time helps you handle unexpected changes or delays. Create a financial buffer for rush fees or expedited shipping if needed. Plan for known risks, such as international holidays, when you source jeans overseas. Buffer periods give you peace of mind and help you deliver your denim collection on schedule.

Schedule extra weeks beyond factory estimates.

Include contingency time after sampling.

Prepare for rush fees or shipping costs.

Account for holidays and other risks.

Choosing the Right Partner

Selecting the right manufacturing partner is key to managing your jeans production lead times. Define your sourcing strategies to stay within budget and avoid delays. Understand lead times by working backward from your delivery date. Evaluate supplier capabilities, comparing local and offshore options for cost and transit times. Build strong relationships with your suppliers. Open communication builds trust and can improve pricing and lead times for your jeans orders.

Criteria | Why It Matters |

|---|---|

Sourcing strategies | Keeps your jeans project on budget |

Lead time awareness | Ensures on-time delivery |

Supplier capabilities | Matches your production needs |

Relationship building | Improves pricing and timelines |

Note: A reliable partner helps you launch your jeans collection without delays and keeps your brand reputation strong.

You now have a clear roadmap for managing your custom denim production timeline. Key factors like production costs, delivery delays, and quality consistency can impact your schedule:

Factor | Description |

|---|---|

High Production Costs | Denim production involves expensive processes and tight margins. |

Handling Production Delays | Factory capacity and material shortages can affect deadlines. |

Quality Consistency | Inconsistent sizing leads to returns and customer dissatisfaction. |

Meeting Consumer Demand | Customization and sustainability are crucial for modern denim buyers. |

To ensure on-time delivery, you should create a structured calendar, keep your team informed, and partner with reliable suppliers. Use this guide as a checklist for each milestone, from design freeze to launch, to keep your denim project on track.

FAQ

How can you speed up your custom denim production timeline?

You can speed up your timeline by preparing a complete tech pack, choosing in-stock fabrics, and responding quickly to sample approvals. Clear communication with your factory also helps avoid delays.

What is the minimum order quantity (MOQ) for custom denim?

Most factories require an MOQ of 30–50 pieces per style. Some mills set fabric MOQs at 300–500 meters. Always check with your supplier before placing an order.

Can you make changes after bulk production starts?

You cannot make major changes after bulk production begins. Small adjustments may be possible, but they often cause delays and extra costs. Approve all details before production.

What happens if your denim order fails quality control?

The factory may fix or replace defective items.

You might face shipping delays.

Poor quality can hurt your brand’s reputation.

Always inspect samples and set clear quality standards before production.