Is your supply chain ready for 2026? You face increasing risks in your supply chain every year. Disruptions threaten your supply chain and demand proactive solutions. Many leaders now turn to ai-powered fit libraries to strengthen their supply chain. You see ai-powered fit libraries transform how your supply chain adapts and responds. If you want resilience, ai-powered fit libraries can help your supply chain overcome new challenges.

Key Takeaways

AI-powered fit libraries enhance supply chain resilience by predicting risks and improving decision-making.

Proactive demand forecasting with AI reduces inventory errors by 20-50%, helping you avoid stockouts and overstocking.

Investing in AI technology now prepares your supply chain for future disruptions, ensuring smoother operations.

Real-time monitoring with AI allows for quick responses to changes, minimizing downtime and enhancing efficiency.

Building a strong data governance framework is essential for successful AI integration in your supply chain.

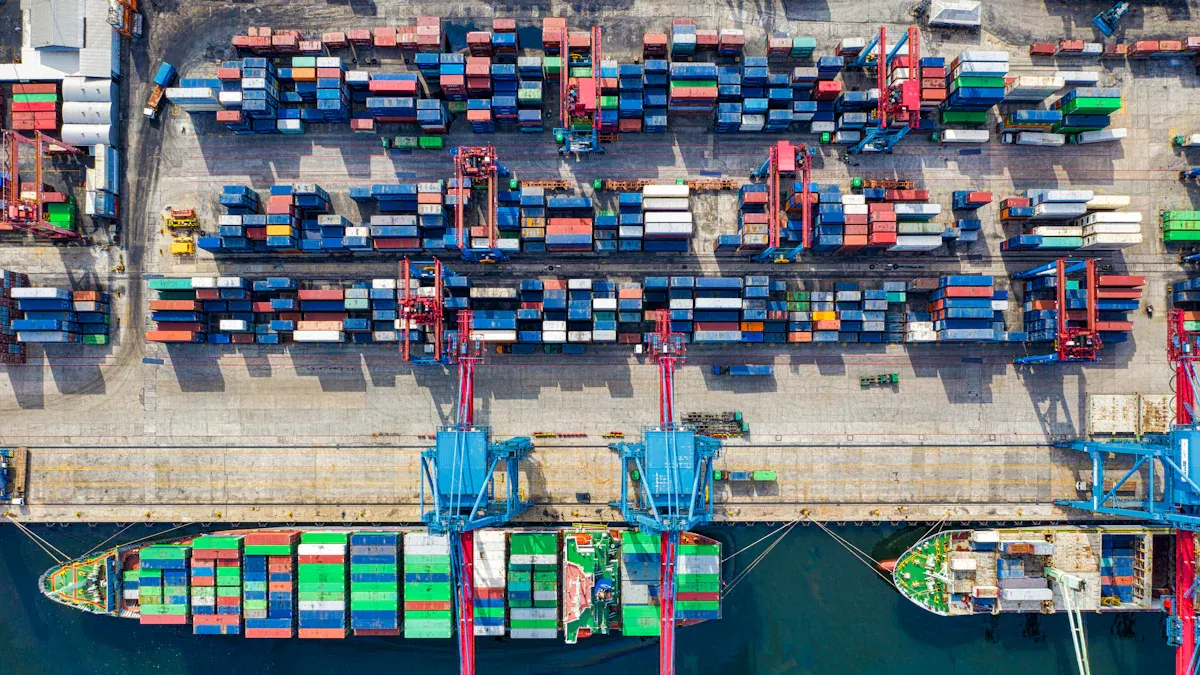

Supply Chain Disruption in 2026

Rising Risks and Volatility

You face a new era of supply chain disruption as 2026 approaches. The risks you manage today will only grow more complex. You must watch for several sources of volatility that can impact your operations:

Elevated tariffs now create cost spikes and unpredictable pricing. You see tariffs as a permanent part of your business landscape.

Derivative exposure increases your risk. Changes in how components are classified can lead to sudden cost increases.

Supplier stability becomes less reliable. Tariffs force suppliers to change their behavior, making relationships unpredictable.

You also experience the impact of these risks in real time. For example:

Tariffs have forced US manufacturers to source parts from countries like Vietnam or Mexico. You deal with new shipping routes and longer transit times.

Increased costs for imported goods affect your warehouse operations. You may need to pass these costs to your customers, which can reduce demand.

Inventory stockpiling to avoid tariff hikes pushes your warehouses to operate near capacity. This strains your storage space and complicates inventory turnover.

Extreme weather events, such as record-breaking temperatures, floods, and wildfires, disrupt global supply chains. You may see delivery delays, shipment reductions, and even major shipping channels slowed by droughts.

Note: Flash flooding in Dubai once submerged an international airport, impacting global shipping routes. Wildfires in Canada caused delivery delays of up to two days and reduced shipments by as much as 75%.

The Cost of Unpreparedness

If you do not prepare for disruptions, you face hidden costs that go beyond immediate penalties. You must divert resources from strategic planning to address urgent issues. This shift impacts your long-term growth and competitiveness. A risk-averse mindset can prevent you from expanding your business and lead to missed opportunities.

You can learn from recent examples:

Nike lost $100 million in revenue and saw a 20% drop in stock value after a supply chain planning glitch.

Cisco faced a $2.2 billion inventory write-down due to poor demand visibility.

Prepared supply chains recover faster because you invest in resilience strategies like supplier diversification and inventory buffering. You can reroute shipments and use backup suppliers, which reduces downtime. If you remain unprepared, you experience longer recovery times and higher costs from emergency measures and operational losses. Hidden costs, such as lost sales and damage to your brand reputation, can exceed the initial investment in resilience.

AI-Powered Fit Libraries Explained

How AI Transforms Supply Chain

You see ai technology changing the way you manage your supply chain. Instead of reacting to problems, you now use ai supply chain management to make proactive decisions. Machine learning and natural language processing help you improve forecasting and logistics. You can anticipate demand surges before they happen and balance inventory with greater accuracy. Logistics providers use ai supply chain management to reroute fleets instantly when facing congestion or risks. Warehouses automate picking and fulfillment, which removes bottlenecks and reduces errors.

Note: Companies using ai supply chain management report fewer manual errors and faster adaptation to real-world changes. By 2026, most chief supply chain officers expect agents to improve process efficiency.

You also support sustainability by using ai technology to optimize carbon emissions and reduce waste. As you adopt these tools, you upskill your workforce to handle new technologies and workflows.

Key Features and Benefits

You build an ai-powered fit library with several core components:

Data Layer: You use datasets for training models, data pipelines, and labeling services. These shape how your models learn and respond to supply chain challenges.

Development Layer: You design and train models using frameworks like PyTorch or TensorFlow. You track experiments to improve forecasting and performance.

Model Artifact Layer: You manage trained models, weights, and configuration files. You protect and version these assets for reliability.

Deployment and Inference Layer: You package models and use orchestration platforms and API gateways. You focus on security controls to keep your supply chain safe.

Third-party Components: You integrate pre-trained models, open-source libraries, and commercial AI APIs to enhance your supply chain workflows.

You see measurable improvements in efficiency and accuracy. Deep learning algorithms outperform traditional models, reducing errors by up to 87%. Trax’s AI models reach 98% accuracy in extracting data from freight documents. Pattern detection tools cut exception handling time by 70%. You create a supply chain that adapts quickly and delivers better results with ai supply chain management.

AI Fabric Forecasting and Inventory Optimization

Data-Driven Demand Planning

You need to predict what your customers want and when they want it. AI-powered demand forecasting gives you the tools to do this with much greater accuracy. Traditional forecasting methods often rely on simple statistical models. These models struggle to keep up with rapid changes in the market. AI-powered demand forecasting uses machine learning to analyze large amounts of data from many sources. This approach helps you spot patterns and trends that older methods miss.

According to a McKinsey study, AI-driven forecasting can reduce errors by 20-50% compared to traditional methods. This improvement in forecast accuracy means you can avoid both stockouts and overstocking. You keep your shelves full without wasting money on excess inventory. AI-powered demand forecasting also helps you respond quickly to changes in demand, such as sudden spikes or drops.

Many companies have already seen strong results. For example, Whirlpool used an AI-powered procurement system and achieved a 15% reduction in inventory levels. Walmart improved its inventory management and reduced stockouts with AI-powered inventory systems. Amazon increased its revenue by 10-15% through dynamic pricing powered by AI algorithms.

Company | Industry | AI Application | Outcome |

|---|---|---|---|

Whirlpool | Manufacturing | AI-powered procurement system | 15% reduction in inventory levels, 10% increase in supply chain efficiency |

Walmart | Retail | AI-powered inventory system | Efficient inventory management, reduced stockouts |

Amazon | Retail | Dynamic pricing using AI algorithms | 10-15% increase in revenue |

When you use AI-powered demand forecasting, you can expect a 10-20% reduction in inventory levels and a 5-10% increase in service levels. These improvements lead to better inventory optimization and lower costs. You also gain better inventory allocation, which means you put products where they are needed most.

Real-Time Monitoring and Response

You need to react fast when something changes in your supply chain. AI-powered demand forecasting gives you real-time monitoring and response tools. These systems collect data every second, so you always know what is happening. You get early warnings if conditions go outside safe limits. This allows you to act before small problems become big ones.

AI systems collect data in real-time, enabling quick decision-making to address delays or temperature issues.

Early warnings are generated when conditions exceed safe thresholds, allowing for immediate corrective actions.

Predictive analytics anticipate future risks based on historical data, enhancing proactive management.

AI integration with ERP systems allows for real-time data analysis and demand forecasting.

AI combined with TMS optimizes logistics operations by analyzing real-time data for route planning and delivery schedules.

AI connects disparate data sources to identify patterns that signal potential disruptions.

It reduces manual reconciliation work and expedites logistics processes, enhancing overall efficiency.

Wiliot’s platform provides real-time movement data for workflow optimization.

It generates proactive alerts for anomalies in conditions, enhancing monitoring capabilities.

AI-powered demand forecasting also helps you monitor equipment health. You use predictive analytics to spot signs of wear or failure before breakdowns happen. This reduces downtime and keeps your supply chain running smoothly.

Real-time AI monitoring significantly reduces equipment downtime and enhances supply chain reliability through predictive maintenance strategies. By leveraging advanced sensors, machine vision, and AI algorithms, businesses can continuously monitor equipment health, identify potential issues before they escalate, and optimize maintenance schedules, ultimately leading to improved operational efficiency and reduced costs.

You see real results when you use AI for inventory optimization. A next-generation aerospace sensor manufacturer saved $10 million each year, reduced processing time by 10%, and increased productivity by 20%. A European retail giant boosted profit margins by €30 million and saved €3.5 million per year in logistics costs. A coffee retail chain achieved a 15% reduction in inventory. These results show how AI-powered demand forecasting and inventory optimization can transform your supply chain.

You also lower carrying costs by minimizing unnecessary holding expenses. You reduce write-offs by identifying slow-moving SKUs early. You get better ROI from your assets by redirecting resources to high-value activities. A leading shoe retailer improved on-shelf availability by 8.8%, reduced lost sales by 11.95%, and boosted cash flow. Optimized transfers led to a 4% increase in additional sales rep unit ratio, adding $21.4 million in extra sales revenue. Automated processes improved workforce efficiency and strengthened the company’s bottom line.

When you use AI-powered demand forecasting, you gain a supply chain that adapts to change, predicts demand with high accuracy, and keeps your business ahead of the competition.

AI for Supply Chain Resilience

Risk Assessment and Orchestration

You need strong risk assessment to build true supply chain resilience. AI for supply chain resilience gives you predictive supplier risk management that goes far beyond traditional methods. You can use AI to score suppliers based on performance, incidents, and even weather disruptions. AI for supply chain resilience exposes new risks by analyzing geolocation, news, and weather data. You can map your supplier network and spot dependencies that might threaten your operations. AI for supply chain resilience also uses predictive tools to send you alerts based on historical data patterns.

AI for supply chain resilience provides objective scoring of supplier performance.

It identifies alternate suppliers for diversification and mitigating risk.

AI for supply chain resilience simulates the impact of disruptions on inventory and costs.

It uses natural language processing to scan news for early signs of instability.

AI for supply chain resilience maps your supplier network and gives you predictive alerts.

AI-powered risk management helps you orchestrate responses in real time. You can analyze data from many sources to predict delays and optimize inventory. AI for supply chain resilience automates responses to disruptions through specialized agents. These agents detect exceptions, analyze the situation, and recommend actions. You can address issues before they escalate. This shift from manual to automated decision-making systems improves your supply chain reliability and efficiency. You gain customized scenario planning and material resource planning that adapts to changing conditions.

Tip: Use AI for supply chain resilience to anticipate risks and recommend mitigation strategies. This approach keeps your supply chain agile and ready for any challenge.

Integrating Supply Chain Artificial Intelligence

You face challenges when you bring supply chain artificial intelligence into your business. High startup costs for hardware, software, and skilled staff can slow your progress. You may worry about system downtime during integration or updates. Data quality and integration issues require clean, well-structured data. You need ongoing maintenance and updates to keep your AI for supply chain resilience effective. Scalability can become a problem as your supply chain grows more complex.

Transitioning to supply chain artificial intelligence also means changing your company culture. Employees may feel uncertain about their roles. You can help by offering clear communication and training programs. Start with small projects to build comfort with AI-driven automation. Address resistance by showing proven results and building trust.

Regulatory requirements and bias risks are important. Algorithmic bias can lead to unfair outcomes if your data is flawed. You must follow new laws like the EU Artificial Intelligence Act and other global standards. These rules demand transparency, accountability, and fairness in your AI for supply chain resilience. Compliance shows your customers and partners that you govern AI with care.

To integrate AI for supply chain resilience with your existing systems, follow best practices:

Plan your resources and budget for smooth implementation.

Standardize data formats for compatibility.

Create APIs or connectors for data sharing.

Validate and verify your data to maintain quality.

Build a strong data governance framework.

You can build trust in supply chain artificial intelligence by forming governance boards, using automated bias detection, and conducting ethical risk assessments. Make AI decisions transparent and let users control how much autonomy they give to AI. These steps help you create an agile fashion supply chain that is ready for the future while mitigating supply chain risk and mitigating risk at every level.

You can future-proof your supply chain by using AI-powered fit libraries. These tools give you early warnings, consistent assessments, and greater efficiency.

You spot risks before they grow.

You free your team to focus on strategy.

You keep your supply chain running smoothly.

Start by benchmarking your current supply chain systems and building an improvement roadmap. The urgency is real—2026 will bring new disruptions. Companies that invest in data quality and agentic AI now will lead in supply chain agility. Explore modern ERP software and platforms like Arena SCI to boost your supply chain resilience.

FAQ

What is an AI-powered fit library in the supply chain?

An AI-powered fit library uses machine learning to analyze data and improve your supply chain decisions. You can use it to match products, predict demand, and optimize inventory. This technology helps you respond faster to changes in your supply chain.

How does AI improve supply chain forecasting?

AI studies large amounts of data to find patterns and trends. You get more accurate forecasts for your supply chain. This means you can plan better, reduce waste, and keep the right products in stock.

Can AI help reduce supply chain disruptions?

Yes, AI can spot risks early and send you alerts. You can act before problems grow. AI helps you keep your supply chain running smoothly, even when unexpected events happen.

What challenges might you face when adding AI to your supply chain?

You may need to update your systems and train your team. Data quality matters. You must also follow new rules and watch for bias. Start small and build trust as you add AI to your supply chain.