You see artificial intelligence changing how manufacturers deliver products. Mass production once focused on cost and scale, but now mass personalization brings flexibility and individual value. The market for AI in manufacturing will reach $155.04 billion by 2030, growing at 35.3% CAGR. Generative AI, robotics, and physical AI let you create products that fit each customer. These advances help you lower costs, improve efficiency, and rethink your business models.

Statistic Description | Value |

|---|---|

Projected market size by 2030 | 155.04 billion USD |

CAGR (Compound Annual Growth Rate) | 35.3% |

Percentage of manufacturers adopting AI tools for scheduling by 2030 | 65% |

Key Takeaways

AI transforms manufacturing by enabling mass personalization, allowing businesses to meet individual customer needs while maintaining efficiency.

Implementing AI can lead to significant cost savings, with automation reducing labor costs by up to 40% and increasing productivity.

Using machine learning for demand forecasting helps businesses reduce waste and optimize production, leading to better resource management.

Personalization strategies driven by AI enhance customer engagement, resulting in higher loyalty and reduced customer acquisition costs.

To successfully adopt AI, businesses should define clear goals, prepare their teams for change, and ensure data quality for effective implementation.

AI Transforms Mass Production

Economic Impact of AI

You see mass production changing rapidly as ai in manufacturing becomes more advanced. Artificial intelligence helps you unlock new economic value by using data to improve every step of the process. Recent industry reports estimate that ai adds between $1.5 trillion and $2.2 trillion to the global manufacturing economy each year. This impact comes from smarter decision-making, reduced waste, and optimized resource usage.

You can use machine learning to analyze data from your production lines. This technology finds patterns that you might miss, helping you minimize waste and use resources more efficiently. Ai-driven automation also lowers labor costs by about 25% on average, with projections showing savings could reach 40% in the coming decades. These changes boost productivity and help your business grow faster. In fact, ai could increase labor productivity in the United States by 1.8% each year, nearly doubling the long-term growth rate.

Here is a table showing how ai-powered systems improve supply chain efficiency in mass production environments:

Application Area | Impact on Efficiency |

|---|---|

Route Optimization | Reduces fuel costs by up to 25% and increases on-time deliveries by 30% |

Warehouse Operations | Increases efficiency and accuracy through intelligent automation |

Production Planning | Boosts overall equipment efficiency by 10% to 15% |

You can see that ai in manufacturing helps your business save money, increase output, and deliver products faster. These improvements make mass personalization possible, allowing you to meet individual customer needs without losing the benefits of scale.

Operational Shifts in Manufacturing

When you use ai in manufacturing, you change how your business operates. Machine learning lets you use data from sensors, machines, and production lines to make real-time decisions. You can optimize schedules, manage energy use, and respond quickly to changes in demand.

Many sectors have seen major shifts. The chemical industry uses ai for workflow automation. The pulp and paper sector improves product processes with machine learning. Oil and gas companies gain operational efficiencies, while food and beverage businesses make better decisions in real time.

You can experience several operational benefits:

Ai helps you create predictable schedules, improving work-life balance for your employees.

Machine learning analyzes shift patterns to prevent fatigue, especially in safety-critical roles.

Ai ensures fair distribution of shifts, promoting justice in your workplace.

You can use data to schedule training and cross-training, helping workers develop new skills.

Real-time production data lets you adjust staffing and resources instantly.

Ai synchronizes order management and workforce schedules, so you meet customer commitments.

Equipment maintenance becomes more efficient with predictive scheduling.

Quality control staffing matches production volumes and product complexity.

Supply chain responsiveness improves, reducing idle time and maximizing productivity.

Your business benefits from these operational shifts. Ai in manufacturing uses both historical and real-time data to refine its understanding of your unique environment. This ongoing learning process helps you anticipate challenges and make smarter decisions. You can optimize logistics by planning routes and loads, reduce travel distance for workers in warehouses, and improve production planning by allocating resources more effectively.

Mass production now supports mass personalization because you can use data and ai to customize products at scale. Machine learning and artificial intelligence give your business the flexibility to meet individual customer needs while maintaining efficiency and cost savings.

Tip: Start by collecting and organizing your production data. The more accurate your data, the better your ai systems will perform.

From Mass Customization to Mass Personalization

Defining the Shift

You have seen mass production shape the way companies deliver goods for decades. Mass customization allowed you to choose from a set of options, but mass personalization takes this further. Now, you can expect products and experiences tailored to your unique preferences. Artificial intelligence drives this change by using data from your interactions, purchases, and feedback. You benefit from ai in manufacturing because it adapts quickly to your needs.

Personalization has evolved with the rise of ai. Today, you see companies using artificial intelligence to customize experiences based on your behaviors. This approach increases engagement and helps businesses build loyalty. By 2025, experts predict that 95% of customer interactions will be ai-driven. You will notice more relevant and timely information, making your experience smoother. Conversational ai technologies focus on hyper-personalization of products, so you get solutions that fit your lifestyle.

Note: Mass personalization creates a “market of one,” where every customer receives products designed just for them.

Hyper-Personalization Strategies

You can use several strategies to achieve mass personalization in your business. Ai in manufacturing relies on data to analyze customer preferences and deliver tailored solutions. Machine learning helps you predict what customers want before they ask. You can use data to optimize product recommendations, emails, and website experiences.

Here is a table showing effective hyper-personalization strategies enabled by ai:

Strategy/Tool | Description |

|---|---|

Personalized Customer Experiences | Ai analyzes data to deliver tailored emails, website experiences, and product recommendations. |

Predictive Analytics | Anticipates market shifts and customer behavior to improve product development and inventory planning. |

Chatbots | Qualify leads, schedule demos, and provide technical information, enhancing customer engagement. |

Voice Search Optimization | Ensures content is discoverable via voice search by analyzing trends and restructuring content. |

Automated Content Creation | Generates optimized material quickly, increasing productivity and maintaining a consistent publishing cadence. |

A/B Testing | Compares different personalized experiences to measure their impact on customer engagement. |

You can use these strategies to create mass personalization at scale. Your business gains a competitive edge by using data and ai to deliver products that match each customer’s needs. You move beyond mass customization and embrace a future where every experience feels personal.

Artificial Intelligence in Manufacturing

Machine Learning and Demand Forecasting

You use machine learning to improve demand forecasting in your business. This technology analyzes large amounts of data from sales, market trends, and customer feedback. Predictive analytics techniques, such as time series analysis and neural networks, help you reduce forecasting errors by up to 50%. As new data arrives, machine learning models adapt quickly, allowing you to respond to market changes. You benefit from reduced excess inventory, lower waste from expired products, and optimized production scheduling. These improvements support mass personalization by helping you anticipate what customers want and adjust your operations for greater flexibility.

Machine learning models use data to predict demand more accurately.

You optimize production scheduling and resource use, lowering costs.

Your business avoids overstocking and reduces waste.

Robotics and Physical AI Integration

You see robotics and physical AI transforming your smart factory. Context-based robotics use perception tools to interpret environments in real time, making tasks more adaptable. AI foundation models allow industrial robots to make decisions and plan with human-like intuition. Companies like Amazon and Foxconn use AI-driven robots to boost efficiency and cut operational costs. Amazon employs over a million robots, improving efficiency by 25% and creating more skilled jobs. Foxconn uses digital twin technology to automate complex tasks, reducing deployment times and error rates. Physical AI bridges digital intelligence and manufacturing by using digital twins and IoT sensors for real-time analysis and production optimization. Autonomous systems control robots and optimize processes, helping your business achieve mass personalization at scale.

Generative AI for Product Innovation

You use generative AI to accelerate innovation in your business. This technology automates complex design tasks, enabling rapid prototyping and experimentation with new concepts. You customize products by analyzing detailed customer data, meeting unique needs and supporting mass personalization. Generative AI reduces research and development time and costs by generating product concepts and engineering drawings. You optimize product designs for sustainability and performance, creating efficient solutions. AI supports predictive maintenance by analyzing data, helping you anticipate issues and minimize disruptions. These advancements allow your business to adapt quickly, deliver personalized products, and stay competitive in the ai native internet era.

Tip: Integrate data from all sources to unlock the full potential of artificial intelligence in your business model.

Benefits of Mass Personalization with AI

Efficiency and Cost Savings

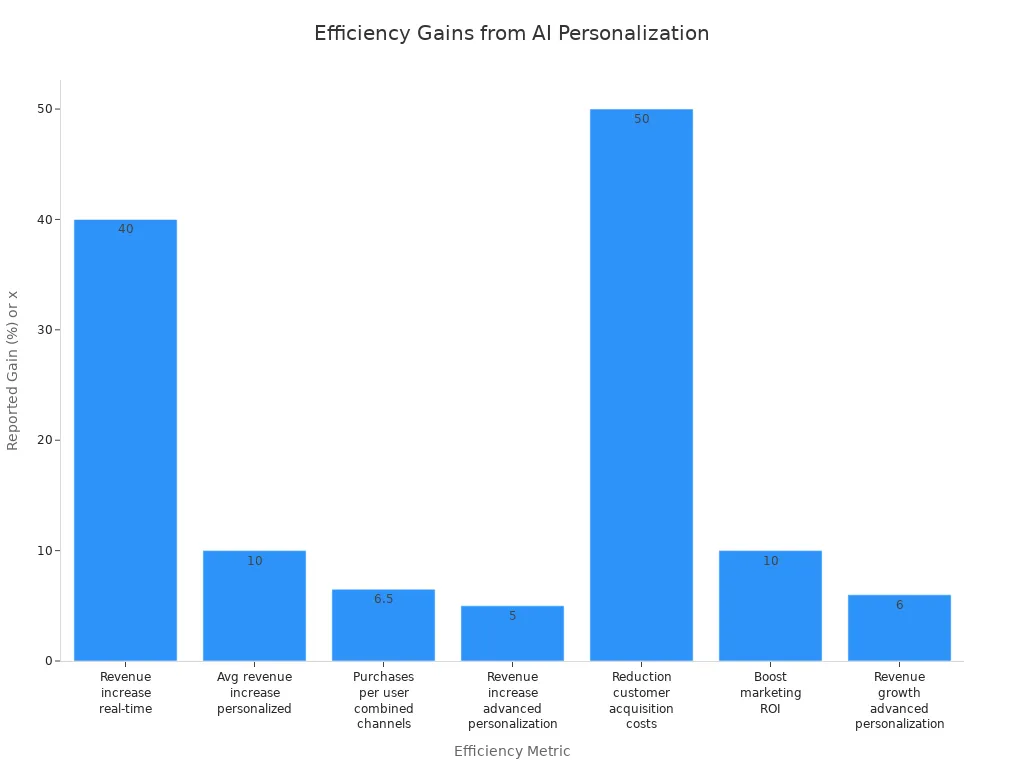

You can see major efficiency gains when you use mass personalization in your business. Companies that excel in real-time personalization report up to a 40% increase in revenue. Personalized production helps you streamline processes and reduce waste. You tailor products to customer needs, which minimizes overengineering and cuts costs. Predictive personalization lets you optimize inventory and logistics, so you avoid excess stock and lower shipping expenses. The table below shows how businesses benefit from these changes:

Metric | Efficiency Gain |

|---|---|

Revenue increase for companies excelling in real-time personalization | 40% revenue increase |

Average revenue increase from personalized experiences | 10-20% average revenue increase |

Purchases per user from combined channel messaging | 6.5x more purchases per user |

Revenue increase from advanced personalization | 5–15% increase |

Reduction in customer acquisition costs | Up to 50% reduction |

Boost in marketing ROI | 10–30% boost |

Revenue growth captured by retailers using advanced personalization | 6–10% revenue growth |

Enhanced Customer Experience

You deliver a better customer experience when you use mass personalization. Customers receive products and services that match their unique preferences. This approach helps you build strong relationships and increase loyalty. Customers who find relevant information stay longer and are more likely to buy. You can reduce customer acquisition costs by up to 50 percent with effective personalization. Your business benefits from higher engagement and conversion rates. You meet customer needs faster and more accurately, which boosts customer satisfaction.

Tailored experiences foster lasting relationships.

Relevant content increases engagement and sales.

Personalization reduces the cost of finding new customers.

Sustainability Gains

You support sustainability goals with mass personalization. AI helps you optimize energy use and reduce waste in your production process. You minimize costs and lower your carbon footprint. Generative AI creates designs that fit customer needs, which leads to less material waste and more efficient production cycles. You can adapt quickly to changes in demand, supporting a circular economy and moving toward a net-zero future. Your business becomes more resilient and environmentally responsible.

Tip: Use generative AI to create efficient designs and meet customer needs while supporting your sustainability goals.

Real-World Use Cases and ROI

Industry Examples

You can find many real-world examples where mass personalization changes how companies operate. Manufacturers use advanced tools to deliver products that fit each customer’s needs. Here are some notable cases:

The Mass Customization Agent helps manufacturers respond to the demand for unique products. This AI-driven tool lets you offer custom options without slowing down your production line.

Leading sportswear brands use digital platforms to let customers design their own shoes. You can select colors, materials, and even add your name. The factory then produces your custom order quickly.

Automotive companies now let you build your own car online. You choose features, and the factory uses flexible systems to create your vehicle just for you.

These examples show how mass personalization can help your business stand out. You meet customer needs while keeping your operations efficient.

Measuring Economic Returns

You want to know if your investment in mass personalization pays off. Companies measure the return on investment in several ways. The table below shows three main categories:

ROI Category | Description |

|---|---|

Direct impacts like cost savings and higher revenue. | |

Strategic ROI | Progress toward long-term goals, such as digital transformation. |

Capability ROI | Growth in skills, new job roles, and readiness for future AI projects. |

You can see measurable ROI when your business reduces inventory costs and avoids lost sales. Strategic ROI appears as your business becomes more efficient and delivers better service. Capability ROI grows as your team learns to use new tools and adapts to change. When you track these returns, you make smarter decisions and build a stronger business for the future.

Tip: Track both short-term gains and long-term growth to see the full value of mass personalization in your business.

Overcoming Challenges in AI Adoption

Implementation Steps

You can succeed with AI in manufacturing by following a clear plan. Start by defining your goals. Set specific objectives for your AI projects. This helps you avoid confusion and keeps your team focused. Next, address cultural factors. Make sure your team is ready to learn new skills and embrace change. Focus on collecting the right data. Good data helps your AI systems work better. Check your machines and systems for connectivity. Legacy equipment may need upgrades or special connections. Finally, use AI tools that give you real-time results. Quick insights help you solve production problems as they happen.

Here is a checklist to guide your implementation:

Define clear goals for your AI projects.

Prepare your team for change and skill development.

Collect and organize relevant data.

Ensure your systems can connect and share information.

Choose AI solutions that provide real-time feedback.

Tip: Start small with pilot projects. Learn from early results before scaling up.

Addressing Barriers

You may face several barriers when adopting AI. Many manufacturers struggle with data fragmentation. Almost half see scattered data as a major obstacle. High-quality data is essential for accurate AI predictions. Skills gaps also create challenges. Most organizations either face skill shortages now or expect them soon. By 2026, almost all companies will feel the impact of IT skill shortages.

The table below shows common barriers and solutions:

Barrier | Solution |

|---|---|

Lack of strategic vision | Create a clear AI roadmap that matches your business goals. |

Data quality, availability, and complexity | Build a strong data governance plan to keep data clean and organized. |

Skills shortage | Offer training programs to help your team learn new skills. |

Cultural resistance to change | Share the benefits of AI and support ongoing learning. |

Ethical concerns and trust issues | Set up ethical guidelines and protect privacy. |

Integration with legacy systems | Use custom APIs to connect AI with your current equipment. |

Mountains of data | Centralize your data storage and use it for predictive analysis. |

You can overcome these challenges with the right strategies. Focus on people, data, and technology to unlock the full value of AI in your manufacturing business.

Future Trends in AI and Manufacturing

Evolving Business Models

You will see new business models change how factories operate. AI-driven mass personalization lets you move away from large, rigid factories. You can now use micro-factories. These are small, flexible, and highly automated. Micro-factories help you produce many different products in small batches. You get high returns because you only make what customers want.

Another model is the dim factory. You do not need to automate everything at once. Dim factories let you automate certain processes or shifts. This approach works well for small and mid-sized businesses. You save money and boost efficiency without a full overhaul.

Business Model | Description |

|---|---|

Micro-factories | Smaller, agile, and highly automated factories that provide high-mix, low-volume customized products with a high return on investment. |

Dim factories | A model that automates specific processes or shifts, enhancing efficiency and reducing costs without full autonomy, suitable for small to mid-sized enterprises. |

Tip: Start with one process. Test automation in a small area before expanding across your factory.

The Next Decade

You will face big changes in the next ten years. Manufacturers in the U.S. may need 3.8 million new workers by 2033. Skills gaps could leave half of these jobs unfilled. You should focus on training and upskilling your team.

Most manufacturers plan to invest at least 20% of their budgets in smart manufacturing. You will see more digital tools and AI systems in factories. Agentic AI will become common. This type of AI can make decisions and manage tasks on its own. Experts predict agentic AI could add up to $650 billion in revenue by 2030. Automation may also cut costs by as much as 50%.

Trend | Description |

|---|---|

Workforce Transformation | U.S. manufacturers may need 3.8 million new workers by 2033, with 1.9 million jobs potentially unfilled due to skills gaps. |

AI and Digital Tool Adoption | Majority of manufacturers plan to invest 20% or more of their budgets on smart manufacturing initiatives. |

Emergence of Agentic AI | Expected to generate up to $650 billion in additional revenue by 2030, with automation yielding up to 50% cost savings. |

Note: You can prepare for the future by investing in your people and technology today.

You see AI changing manufacturing from mass production to true mass personalization.

72% of consumers want businesses to treat them as individuals.

AI gives you 40% faster response times and real-time customization.

Intelligent automation lets you personalize at scale and keep costs low.

AI helps you adapt quickly to customer needs and streamline your supply chain. Over half of manufacturers now use AI tools. As you invest in training and flexible systems, you prepare your business for the future of Industry 5.0.

FAQ

What is mass personalization in manufacturing?

You use mass personalization to create products that match each customer’s needs. AI helps you analyze data and adjust production quickly. You deliver unique items at scale, not just standard options.

How does AI improve efficiency in factories?

You see AI automate tasks and optimize schedules. Machine learning finds patterns in your data. You reduce waste and save time.

Tip: Start with small automation projects to see quick results.

What skills do you need for AI adoption?

You need basic data analysis skills and a willingness to learn new technology. Training programs help you build confidence.

Data literacy

Problem-solving

Adaptability

Can small businesses use AI for personalization?

You can use AI tools even in small factories. Many solutions offer easy setup and low costs.

Benefit | Description |

|---|---|

Affordable | Fits small budgets |

Scalable | Grows with your business |

User-friendly | Simple to operate |