Picture yourself in a denim factory. Machines hum while workers focus on each design detail. You see bolts of denim stacked high and hear scissors snip through thick fabric. Every design choice matters because the world loves jeans. In fact, experts say:

Over 6 billion pairs of jeans will be sold each year by 2029.

You notice how design meets tradition, technology, and sustainability. Each pair of jeans starts with creative design ideas. You wonder how every design step shapes what you wear.

Key Takeaways

Denim production starts with high-quality cotton, which is essential for strong and durable jeans.

Sustainable practices in denim manufacturing, like water-saving technologies, significantly reduce environmental impact.

Skilled workers play a crucial role in every step of the jeans production process, ensuring quality and craftsmanship.

Innovative techniques, such as laser finishing, enhance denim styles while conserving resources and protecting workers.

Recycling and upcycling initiatives help reduce waste and promote a circular economy in the fashion industry.

Raw Materials in Denim Factory

Cotton to Yarn

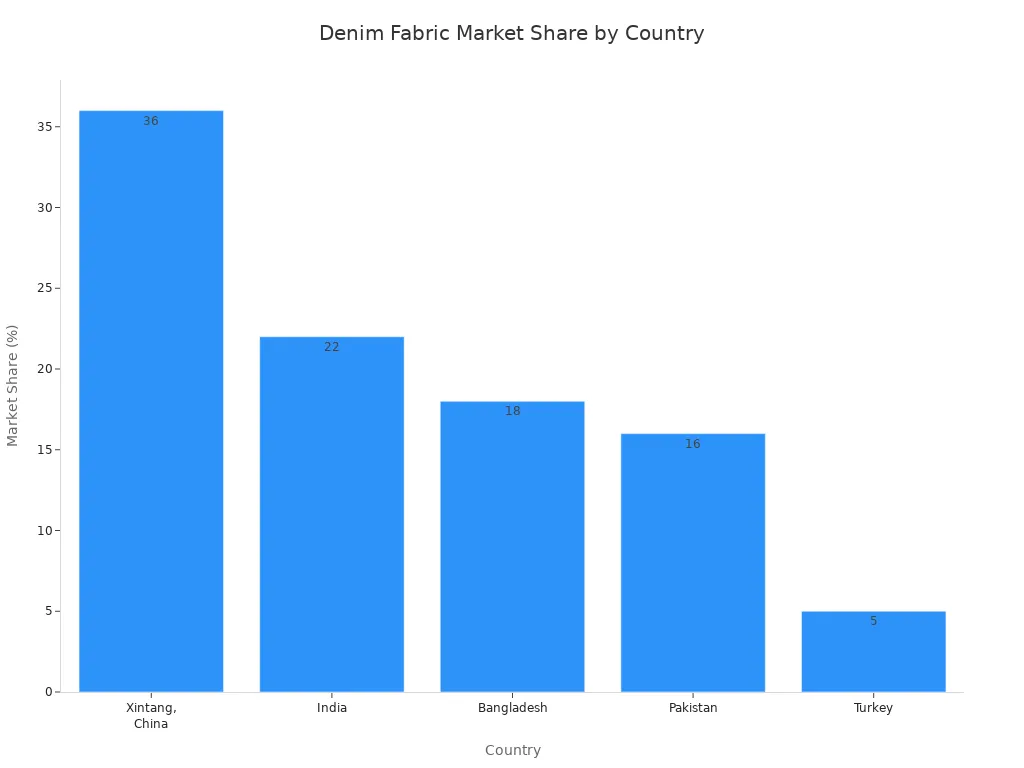

You probably know that every pair of jeans starts with cotton. Cotton is the backbone of denim. Factories source cotton from all over the world, but some countries stand out. Take a look at this table to see which places lead the market:

Country | Share of Global Fabric Production | |

|---|---|---|

Xintang, China | 800 million | 36% |

India | 480 million | 22% |

Bangladesh | 400 million | 18% |

Pakistan | 350 million | 16% |

Turkey | 120 million | 5% |

You see cotton farming in action, where farmers grow and harvest the raw material. After picking, the cotton goes through ginning, which removes seeds and cleans the fibers. Spinning mills then turn these fibers into yarn. You might notice that ring spinning creates a compact, strong yarn, while open-end spinning works faster for mass production. The quality of cotton matters a lot. Long staple cotton gives you stronger yarn, which means your selvedge denim lasts longer and feels better. If you want the best selvedge denim, look for high-quality denim fabrics made from premium cotton.

Here’s a quick rundown of the steps:

Cotton farming

Ginning

Spinning

Weaving

Dyeing

Finishing

You can spot the difference in selvedge denim right away. Yarn from high-quality cotton is dense and less likely to pill. The yarn count affects how thick or fine your denim feels. If you want jeans that hold up, you need strong cotton and careful spinning.

Warp and Weft Preparation

Now, let’s talk about how factories prepare yarn for weaving. You hear about warp and weft all the time in denim. Warp yarns get dyed with indigo, giving selvedge denim its famous blue look. Weft yarns stay undyed or white, which is why the inside of your jeans looks lighter. Indigo dye on the warp creates that cool fading effect you love in selvedge denim.

Machines play a big role here. Slasher warping machines make sure warp yarns stay consistent, so your selvedge jeans feel smooth and strong. Looms weave the yarns tightly, giving you dense, durable denim. Singeing machines remove fuzz, making your selvedge denim last longer. Sanforising machines control shrinkage, so your jeans fit after washing. Inspection machines check for flaws, making sure only the best selvedge denim reaches you.

If you want jeans that stand out, pay attention to the warp and weft. The best selvedge denim uses premium cotton, careful dyeing, and precise weaving. That’s how you get jeans with character and strength.

Denim Fabric Production Process

Spinning and Weaving Denim

You see the journey of denim begin with the spinning process. Workers take cleaned cotton and card it into soft slivers. Machines twist these slivers into yarn, using ring spinning for strength and durability. This step matters because it decides how tough your denim will feel.

Here’s how the process usually goes:

Cotton preparation: Clean and card the cotton.

Spinning: Twist the slivers into yarn.

Dyeing: Color the warp yarns with indigo.

Weaving: Combine dyed warp and undyed weft yarns.

You notice that weaving gives denim its famous look. Factories use twill looms to cross the yarns at an angle. This creates the diagonal lines you see on your jeans. The twill weave does more than look cool. It makes denim flexible and strong.

Tip: The diagonal pattern helps your jeans last longer and stretch without tearing.

Check out this table to see why the twill weave stands out:

Benefit | Explanation |

|---|---|

Diagonal Pattern | Reduces the risk of tear and increases durability by spreading stress. |

Flexibility | Lets the fabric bend and stretch without damage. |

Durability | Prevents wear and tear, perfect for workwear and outdoor use. |

Indigo Dyeing Techniques

Factories use special dyeing techniques to give denim its deep blue color. You might hear about rope dyeing, where workers twist yarn into ropes and dip them in indigo baths many times. This process creates rich color and beautiful fading over time. Slasher dyeing is another method. It runs sheets of yarn through indigo baths, making the process faster and more efficient.

Modern dyeing methods help the environment. Some factories use less energy and fewer chemicals. Others get dye from onion peels or avocado seeds. New techniques like enzymatic extraction and microbial fermentation make the process safer and greener. You get denim that looks great and supports a cleaner planet.

Jeans Production Process in Factory

Cutting and Sewing Jeans

You step into the heart of the denim factory and see the real action begin. This is where the jeans production process gets hands-on. Every pair of jeans starts as a design sketch. Designers create tech packs that show every detail, from pocket shape to stitching style. You watch as workers select the right denim for each style. They check for color, weight, and texture to match the vision.

Here’s a look at the main steps you’ll find in the jeans production process:

Stage | Description | Key Deliverable |

|---|---|---|

Design & Tech Packs | Initial design and technical specifications for the jeans. | Concept sketches |

Fabric Sourcing | Selecting appropriate materials for production. | Fabric selection |

Prototyping & Sampling | Creating initial samples to evaluate design and fit. | Sample garments |

Pattern Development | Developing patterns and grading for different sizes. | Size patterns |

Cutting & Sewing | Actual cutting of fabric and sewing pieces together. | Bulk production run |

Finishing & Wash Treatments | Final touches and washing processes to enhance the product. | Finished jeans |

Quality Control | Ensuring the final product meets quality standards. | Quality assurance report |

You see machines spread out layers of denim, ready for cutting. Workers use automated cutting machines for speed and accuracy. Sometimes, they use manual cutters for special shapes. The cut pieces move to the sewing area. Here, skilled workers use different machines to assemble the jeans. You notice single-needle lockstitch machines for zippers, double-needle chainstitch machines for strong seams, and bartack machines for stress points. Pocket setters make sure every back pocket sits just right.

The jeans production process moves fast, but every step matters. Workers attach waistbands, sew buttonholes, and check every seam. You can feel the energy as the factory brings each pair of jeans to life. The focus on quality never stops. Inspectors check for even stitching, smooth seams, and perfect fits. Only the best jeans move on to the next stage.

Tip: If you want jeans that last, look for brands that invest in quality control at every step.

Artisan Finishing and Detailing

Now, you reach the most creative part of the jeans production process. This is where jeans get their unique look and feel. The finishing stage transforms plain denim into distressed, faded, and pre-faded jeans that stand out in your closet.

Artisans use many techniques to create different effects. Here’s a table that shows some of the most popular methods:

Technique | Description |

|---|---|

Stone Wash | Uses pumice stones for mechanical abrasion, giving jeans a rugged, distressed look. |

Enzyme Wash | Uses cellulase enzymes to fade denim gently, making the process eco-friendlier and giving a soft handfeel. |

Potassium Permanganate Spray | Applied locally for highlights, often with whiskering and hand sanding. Needs special treatment after. |

You see workers hand-sanding the thighs and knees to create natural wear marks. They use sand wash for a soft, textured surface. Hand brushing adds faded spots and whiskers, making each pair of jeans unique. The washing process includes stone washing, enzyme washing, and sand washing. These steps give you the distressed and pre distressed jeans you love.

Modern technology has changed the game. Laser treatments now create high-definition patterns, fading, and distressed effects without using much water or chemicals. Factories use lasers to add whiskers, rips, and even custom designs. This method saves water, cuts down on chemicals, and keeps workers safe. Lasers can process up to 200 pairs of jeans per hour, making production faster and more efficient.

Here’s a quick look at how laser finishing helps:

Benefit | Description |

|---|---|

Water Conservation | Reduces water usage by up to 67%, making the washing process greener. |

Reduction in Chemical Usage | Cuts down on harmful chemicals, making the jeans production process safer and more sustainable. |

Energy Efficiency | Uses 62% less energy than old methods, lowering production costs. |

Increased Production Efficiency | Processes up to 200 pairs of jeans per hour, boosting output. |

Worker Safety | Removes risks from traditional washing and distressing methods. |

You also see new eco-friendly methods in action. Factories use bio-based enzymes and ozone treatments to create faded and distressed looks. These methods give you soft, pre-faded jeans with less impact on the planet. The washing process now uses less water and energy, but still delivers the faded, vintage styles you want.

The final step in the jeans production process is quality control. Inspectors check every detail, from the evenness of the faded areas to the strength of the distressed spots. Only jeans that pass strict quality checks reach the store. When you pick up a pair of pre distressed jeans or pre-faded jeans, you hold the result of careful work, creative finishing, and advanced technology.

Note: The next time you wear your favorite distressed jeans, remember the skill and innovation behind every faded line and worn patch.

Sustainability in Denim Manufacturing

Water and Chemical Reduction

You might not realize how much denim manufacturing impacts the planet. Traditional production uses a lot of water and chemicals. In fact, about 24% of denim finishing relies on hazardous chemicals, which can harm both the environment and workers. Each pair of jeans can use up to 30 liters of water during finishing, much higher than the recommended 22.5 liters. Denim manufacturing stands out for its heavy water and chemical use compared to other clothing.

Factories now focus on eco-friendly solutions. Sustainable denim manufacturing uses new technologies to cut water and chemical use. Some washing methods save up to 95% of water and reduce harmful chemicals. Waterless dyeing has changed the game, lowering environmental impact by as much as 95%. You see more factories using laser technology, ozone washing, and nanotechnology. These methods not only save water but also make the process safer for workers.

Here’s a quick look at how different technologies help:

Technology | Water Savings | Chemical Discharge |

|---|---|---|

Enzyme Wash | –35% | Biodegradable |

Ozone Wash | –70% | Zero residue |

Laser Fading | –100% | None |

When you choose eco-friendly jeans, you support factories that use less water and fewer chemicals. Some best practices now use less than 0.5 liters of water per pair, compared to older methods that used over 1.5 liters.

Recycling and Upcycling Denim

Sustainability in denim manufacturing goes beyond saving water. Recycling and upcycling play a huge role in eco-conscious manufacturing. Many brands now collect old jeans and turn them into new products. Programs like Blue Jeans Go Green™ encourage you to recycle denim instead of throwing it away. This keeps denim out of landfills and gives it a second life.

Check out some of the most effective recycling and upcycling initiatives:

Initiative | Description |

|---|---|

Patagonia’s Worn Wear | Lets you trade in used denim for store credit. The company repairs or recycles the material. |

American Eagle & Give Back Box | Offers free shipping for old jeans, making recycling easy for everyone. |

Bonded Logic | Turns old jeans into insulation for buildings. |

New Textiles | Uses recycled denim in new clothing, cutting down on new cotton use. |

Accessories | Upcycles denim into bags, shoes, and more, giving the fabric a longer life. |

You can also try zero waste fashion, where every scrap of denim gets used. Upcycled denim becomes unique designs, and DIY projects let you create your own eco-friendly style. These sustainable practices help reduce waste and inspire creativity.

Tip: When you recycle or upcycle your old jeans, you help build a more sustainable future for denim manufacturing.

People and Craftsmanship in Denim Factory

Roles of Skilled Workers

When you walk through a denim factory, you see teamwork in action. Every skilled worker brings something special to the table. You notice how each stage of denim production relies on people who know their craft. Machine operators keep yarn spinning smoothly. Technicians adjust weaving tension to make sure the fabric stays strong and even. In the cutting room, workers handle sharp tools with care, making sure every piece fits the pattern. Sewing experts stitch seams, attach pockets, and add zippers or buttons. In the finishing area, workers check every detail before jeans reach the store.

Here’s a quick look at how skilled workers shape each stage:

Stage | Role of Skilled Workers |

|---|---|

Yarn Production | Skilled operators monitor machines to adjust thread tension and ensure consistency. |

Weaving | Technicians adjust tension to achieve balanced fabric and reduce defects. |

Cutting | Skilled workers prepare and cut fabric pieces accurately for assembly. |

Sewing | Workers stitch seams, attach pockets, and add zippers or buttons to garments. |

Finishing | Skilled workers ensure quality control and finalize the garment for sale. |

You can see that denim production is more than machines. It’s about people who care about every detail.

Quality Control and Attention to Detail

You want your jeans to look great and last long. That’s why quality matters at every step. In a denim factory, workers check for weaving defects, shade differences, and stains during fabric inspection. They test trims like zippers and buttons to make sure they work well. When cutting, they match each panel to the pattern and check for flaws. Sewing teams inspect stitching for strength and evenness. During washing and finishing, they look for color consistency and the right faded effect.

Quality control doesn’t stop there. Workers measure every pair of jeans to match size charts. They classify defects as major, minor, or critical. Before shipping, inspectors use AQL-based checks to make sure each batch meets standards for wash, color, fit, and finish. If they find problems, they fix them or send them back for repair. Factories also use safer dyes and keep clients updated with clear reports.

Tip: When you choose denim made with care, you support skilled workers and get jeans that stand the test of time.

You’ve seen how a denim factory transforms cotton into your favorite jeans. Each stage matters:

Cotton becomes yarn, then denim fabric.

Skilled hands and new technology shape every pair.

Sustainable steps protect the planet.

Sustainability Efforts | Impact |

|---|---|

Water-saving technologies | |

Non-toxic dyeing | Lower water pollution |

Recycling and circular economy | Cut down on waste |

Next time you wear jeans, remember the care, skill, and innovation behind every stitch.

FAQ

How long does it take to make a pair of jeans?

You can expect a pair of jeans to take anywhere from 6 to 12 hours to complete. The time depends on the design, finishing techniques, and factory workflow.

What makes selvedge denim different from regular denim?

Selvedge denim uses a tighter weave and premium cotton. You get a cleaner edge and stronger fabric. Many people love selvedge for its durability and classic look.

Can you explain the step-by-step guide for faded jeans?

You start with raw denim. Workers use washing, sanding, and sometimes lasers to create fading. Each step adds character and helps shape how faded jeans look over time.

Are sustainable jeans really better for the environment?

You help the planet when you choose sustainable jeans. Factories use less water, fewer chemicals, and recycled materials. These steps reduce pollution and waste.

How do I care for my jeans to keep them looking great?

You should wash jeans inside out in cold water. Air dry them to prevent shrinking. Avoid harsh detergents. This helps your jeans keep their color and shape.