You see new technologies in denim factories promising less pollution and lower water use. Many brands highlight eco-friendly denim innovations, but you might wonder how much the industry has truly changed.

Only 27% of global denim production uses waterless dyeing methods.

Trend | Fact |

|---|---|

Consumer Preference | Half of shoppers choose brands with recycled denim or sustainable washes. |

Water-Saving Technologies | Factories can cut water usage by over 80%. |

Organic Cotton Demand | Demand jumped 23% in North America and Europe last year. |

Brand Transparency | Transparent brands grow 15% faster in premium markets. |

Social Media Influence | Online denim sales rose 22% due to eco-fashion buzz. |

You should consider both the benefits and the limits of these changes as you explore the future of denim.

Key Takeaways

Eco-friendly denim production is on the rise, with technologies like ozone and laser finishing cutting water use by up to 96%.

Choosing jeans made from recycled materials can significantly reduce waste and lower your carbon footprint.

Look for certifications like GOTS or Fair Trade to ensure your denim is truly sustainable and ethically produced.

Consumer demand for transparency and sustainable practices is driving brands to adopt eco-friendly innovations in denim production.

You can support a sustainable future by choosing brands that prioritize eco-friendly methods and materials.

Denim’s Environmental Impact

Water and Energy Use

You might not realize how much water goes into making your favorite pair of jeans. On average, manufacturers use about 7,500 liters of water for just one pair. Most of this water irrigates cotton fields. This high demand puts stress on water-scarce regions. Factories also use large amounts of energy to spin, dye, and finish denim. When you add up all the steps, denim production leaves a big environmental footprint.

Did you know? Producing one pair of jeans can require as much water as you drink in seven years.

Here’s a quick look at the main impacts of traditional denim manufacturing:

Environmental Impact | Description |

|---|---|

Water Consumption | Producing one pair of jeans requires around 3,781 liters of water, impacting water-scarce regions. |

Chemical Use | The industry consumes 50,000 tons of synthetic indigo dye and 84,000 tons of sodium hydrosulfite annually, which are hazardous. |

Carbon Emissions | Average jeans emit between 10 and 30 kilograms of CO2, contributing to a total of 1.2 billion tonnes from the textile industry. |

Waste Management | A billion pairs of jeans end up in landfills, as retailers prefer disposal over recycling. |

Effluent Release | Denim production releases 40 to 65 liters of colored wastewater per kilogram, polluting waterways. |

Chemical Pollution

You face another problem with denim: chemical pollution. Factories use synthetic dyes and bleaching agents to get the right color and finish. Each year, the industry uses about 50,000 tons of synthetic indigo dye and 84,000 tons of sodium hydrosulfite. These chemicals can leak into rivers and soil, harming plants, animals, and people. Eco-friendly practices aim to reduce this pollution by using safer dyes and better wastewater treatment.

Waste and Emissions

Denim production creates a lot of waste. The global textile industry generates about 92 million tonnes of textile waste every year. That is like throwing away a garbage truck full of clothes every second. Most of these clothes end up in landfills or get burned. The fashion industry also produces huge amounts of greenhouse gases—between 2% and 8% of all global emissions. Eco-friendly practices help by recycling old denim and cutting down on waste and emissions.

Eco-Friendly Denim Innovations

Ozone and Laser Technology

You see a big shift in denim finishing with ozone and laser technology. These eco-friendly denim innovations help you reduce the environmental impact of your jeans. Ozone technology uses ozone gas to bleach and fade denim, while laser technology creates patterns and worn effects without water or harsh chemicals.

Ozone and laser methods reduce chemical dependency, so you see less pollution in rivers and soil.

These processes conserve water and energy. Ozone finishing can cut water use by up to 96% and energy by 25%. Laser washing reduces water use by up to 90% compared to traditional methods.

Ozone breaks down into oxygen, leaving no harmful residues behind.

Jeanologia’s G2 ozone technology lets you create vintage looks without using water or toxic chemicals. You get the same style with a much smaller environmental footprint.

Traditional denim finishing uses hundreds of liters of water and many chemicals for each pair of jeans. Ozone and laser technologies let you achieve the same effects with a fraction of the resources. You help keep waterways cleaner and save energy at the same time.

Waterless Dyeing and Recycling

You might wonder how denim can be dyed without water. Supercritical CO2 dyeing is one of the most impressive eco-friendly denim innovations. This process uses pressurized carbon dioxide instead of water to apply color to fabric.

Technology | Water Consumption | Energy Consumption | Chemical Usage |

|---|---|---|---|

Supercritical CO2 Dyeing | None | Reduced | Lowered |

With supercritical CO2 dyeing, you eliminate water use and lower energy needs. The process also allows you to recycle both CO2 and unused dyes, making it a sustainable innovation in the denim industry. These innovative dyeing techniques help you cut down on pollution and resource use.

Recycling plays a huge role in reducing denim waste. Many mills now use recycled cotton fibers to make new fabrics. If you reuse fibers even once or twice, you can lower global fiber consumption by 40-60%. Using 50% recycled fibers in denim garments can also reduce global warming impacts and save resources. When you choose jeans made from recycled materials, you help keep waste out of landfills and support a circular fashion system.

Sustainable Fibers and Natural Dyes

You can make denim even more eco-friendly by choosing sustainable fibers and natural dyes. Organic cotton uses up to 91% less water when rain-fed compared to regular cotton. It also helps soil stay healthy and stores more carbon, which is good for the planet. Recycled polyester (rPET) gives new life to plastic bottles—one rPET garment can reuse 15–20 bottles. Producing rPET uses 59% less energy and creates 32% fewer carbon emissions than making new polyester from oil.

Natural dyes offer another sustainable innovation. They are biodegradable and non-toxic, so they do not harm the environment or your health. Natural dyes also use less water—about half as much as synthetic dyes. When you pick denim colored with natural dyes, you support cleaner rivers and safer working conditions for factory workers.

Tip: Look for denim labeled with organic cotton, recycled polyester, or natural dyes. These choices help you support eco-friendly denim and reduce your environmental footprint.

Eco-friendly denim innovations like water recycling, ozone and laser finishing, innovative dyeing techniques, and sustainable fibers are changing the industry. When you choose these options, you help drive sustainable innovation and protect the planet for future generations.

Comparing Sustainable Denim to Traditional Methods

Environmental Benefits

You can see clear differences when you compare sustainable denim production to traditional methods. New technologies help you save water, energy, and chemicals. The table below shows how these improvements look in practice:

Metric | Sustainable Denim Production | Traditional Methods |

|---|---|---|

Water Usage | Reductions of 50%-60% with innovative technologies | High water usage in cotton cultivation and dyeing |

Energy Usage | Optimized machinery and processes | Generally higher energy consumption |

Chemical Usage | Fewer chemicals needed due to advanced techniques | More chemicals used in traditional processes |

You help the planet when you choose jeans made with these new methods. For example, MUD Jeans emits 66% less CO₂ compared to similar products from Levi’s. The water footprint drops by 80%. Land occupation falls by 48%. These numbers show that sustainable denim can make a big difference for the environment.

You reduce your carbon footprint by choosing brands that use recycled fibers.

You support cleaner rivers and healthier soil when you pick jeans made with water recycling and fewer chemicals.

You help lower greenhouse gas emissions by supporting companies that use renewable energy.

Cost and Scalability

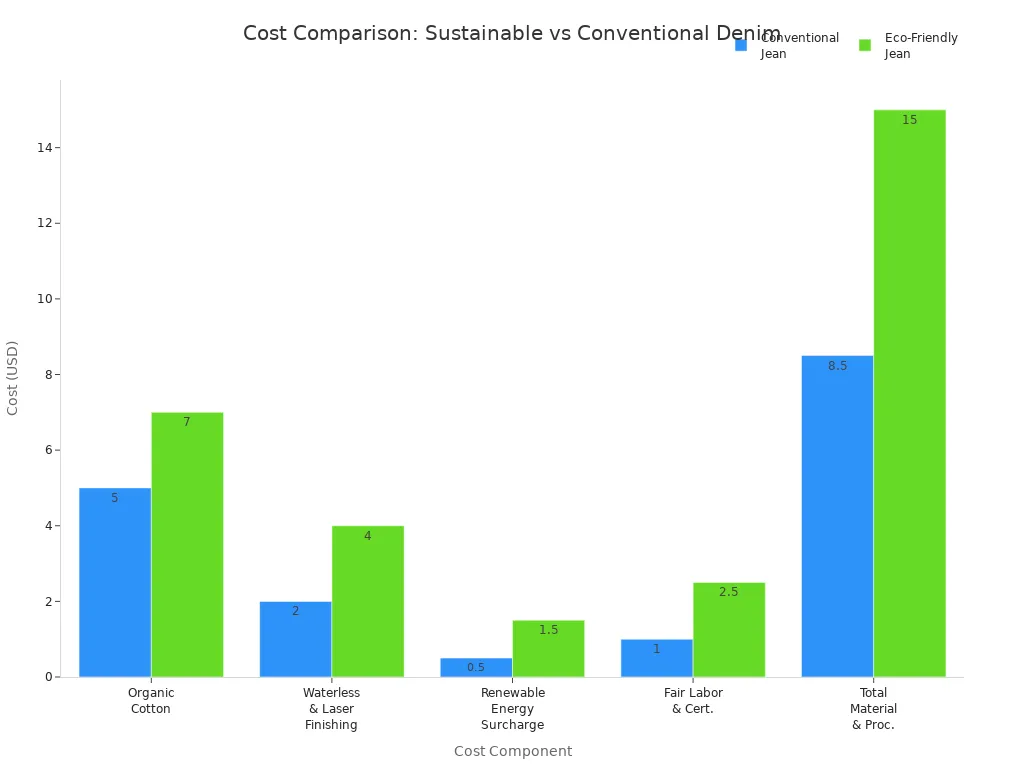

You might wonder if sustainable denim costs more. The answer is yes, but you should know why. The table below compares the cost of making a conventional jean with an eco-friendly one:

Cost Component | Conventional Jean | Eco-Friendly Jean | Δ (%) |

|---|---|---|---|

Organic Cotton | $5 | $7 | +40% |

Waterless & Laser Finishing | $2 | $4 | +100% |

Renewable Energy Surcharge | $0.50 | $1.50 | +200% |

Fair Labor & Certification | $1 | $2.50 | +150% |

Total Material & Processing | $8.50 | $15.00 | +76% |

You pay more for sustainable denim because organic cotton, waterless finishing, and fair labor cost extra. These costs can make eco-friendly jeans almost twice as expensive. Large manufacturers can scale up these innovations, but they need to invest in new machines and train workers. You see companies like Isko leading the way by meeting strict environmental standards and using recycled fibers. When big brands adopt these methods, they can cut carbon emissions by 50–60% and reduce water and energy use by up to 50%.

Companies use AI forecasting and micro-factory partnerships to lower waste and inventory risk.

High upfront costs mean brands must work together to get a good return on investment.

Ongoing Challenges

You still face many challenges with sustainable denim. Old habits in the industry make change slow. Some factories do not want to spend money on new technology. Global supply chains are complex, so switching to eco-friendly methods takes time.

Many companies stick to traditional practices, which slows progress.

High costs stop some brands from investing in sustainable denim production.

Complicated supply chains make logistics harder.

Factories need new ideas to improve production methods.

Environmental rules can raise costs for eco-friendly alternatives.

Water-intensive processes remain a concern in some regions.

Prices for raw materials change often, making planning difficult.

Political tensions can disrupt supply chains.

You also see limits in durability and consumer acceptance. Upcycled denim can cost more, which may turn away price-sensitive shoppers. Quality can vary, so some people do not trust upcycled jeans. Many consumers do not know enough about the durability or style of sustainable denim, which slows adoption.

Tip: You can help by learning more about sustainable denim and asking brands about their production methods. Your choices push the industry to improve.

Industry Adoption and Barriers

Leading Brands and Early Adopters

You see many brands leading the way in sustainable fashion. These companies use new materials and eco-friendly processes to reduce their impact on the planet.

Reformation uses organic cotton, Tencel, and elastane in its denim. The company produces jeans in Turkey and saves thousands of gallons of water with its eco-friendly methods.

You can also learn from early adopters who have made big changes in their production. The table below shows how some companies have used innovation to make denim more sustainable:

Company | Innovation | Impact |

|---|---|---|

Levi’s | Waterless Technologies | Reduced water usage by up to 96%, saving over 3.5 billion liters since 2011. |

Recover | Essential Denim Collection | Offers denim staples that balance performance, style, and sustainability through recycled fibers. |

Collaborative Study | Circular Economy | Explores co-creation in the denim industry, enabling circular product innovation and fostering new business connections. |

Barriers to Full-Scale Change

You still face many barriers when trying to make denim production fully sustainable. Some of the biggest challenges include:

Many factories lack the technical knowledge needed for new eco-friendly methods. Without this knowledge, progress is slow.

High import taxes on equipment like ozone and laser systems make it hard for companies to invest in better technology.

High interest rates on loans create uncertainty and make financial planning difficult.

Global supply chains are complex and fragmented. This makes it hard to ensure quality and follow environmental rules.

Regulators and consumers now watch brands more closely, so companies must rethink how they source materials.

Balancing costs with compliance is important to keep consumer trust and protect brand reputation.

Note: Overcoming these barriers will require teamwork between brands, suppliers, and governments.

Consumer Awareness

You play a big role in the shift toward sustainable fashion. Today, more people care about how their clothes are made and want brands to be transparent.

You and other shoppers expect brands to use sustainable practices.

There is strong demand for transparency and ethical choices.

Gen Z and millennials lead the way, making sustainability a top priority in their fashion decisions.

Recycling denim fibers and using organic cotton drive eco-friendly innovation.

The use of recycled denim has grown by 20%, showing the power of consumer demand.

Brands that focus on sustainability gain more support, especially in premium and mid-range markets.

The rise of circular fashion encourages recycling and upcycling, giving brands new ways to innovate.

You help shape the future of denim by choosing products that support sustainable fashion. Your choices push brands to improve and adopt better practices.

You have seen major progress in eco-friendly denim, such as Shein’s Cool Transfer Denim Printing, which increased sustainable output by 90% and cut water use by 70.5%. However, water-intensive processes, chemical pollution, and labor practices still challenge the industry.

Year | Eco-Friendly Output | Water Usage Reduction (%) |

|---|---|---|

2024 | 380,000 pairs | 70.5 |

You can support change by choosing ethical denim. Brands should invest in new technologies, partner with certification bodies, and focus on long-term savings. Your choices and industry innovation will shape a truly sustainable future for denim.

FAQ

What makes denim eco-friendly?

You can call denim eco-friendly when brands use less water, fewer chemicals, and recycled or organic materials. Factories that use renewable energy and safe dyes also help protect the environment.

How can you tell if your jeans are sustainable?

Look for certifications like GOTS, OEKO-TEX, or Fair Trade. You can also check if brands share details about water use, recycled fibers, or natural dyes. Transparency signals true sustainability.

Do eco-friendly jeans last as long as regular jeans?

Yes, you can expect eco-friendly jeans to last just as long as traditional ones. Many brands focus on quality and durability, so you get strong, long-lasting denim.

Are recycled denim jeans comfortable?

You will find recycled denim jeans comfortable. Brands blend recycled fibers with new materials to keep the fabric soft and flexible. You get comfort without sacrificing sustainability.

Can you recycle your old jeans?

Yes! Many brands and stores offer denim recycling programs. You can drop off your old jeans, and they will turn them into new products or insulation materials.