Choosing reliable jeans manufacturers in China plays a key role in your business success. You need to focus on quality, cost, and trust. Many brands face risks like scams and poor workmanship. China produces more than half of the world’s jeans:

Strong production capacity

Wide range of suppliers

Smart sourcing helps you avoid common mistakes and reach your goals.

Key Takeaways

Define your product specifications clearly. Consider fabric, fit, and style to avoid misunderstandings with manufacturers.

Research manufacturers thoroughly. Use online platforms and sourcing agents to find reliable suppliers and verify their credentials.

Request samples before placing bulk orders. Evaluate the quality and ensure the denim meets your brand’s standards.

Understand pricing structures and minimum order quantities. Larger orders often reduce costs, while customization may increase them.

Establish strong communication and build trust with your manufacturer. Regular updates and respect foster long-term partnerships.

Define Product and Quality Needs

Set Specifications and Target Market

You need to start by defining what kind of jeans you want to produce. Think about your target market. Are you aiming for youth fashion, workwear, or premium denim? Each segment has different expectations for style, fit, and durability. When you work with china jeans manufacturers, clear specifications help you avoid misunderstandings and ensure consistent results.

Here are key factors to consider when setting your product specifications:

Fabric selection: Choose denim that matches your brand’s comfort and durability goals.

Pattern making: Accurate patterns guarantee the right fit and style for your jeans.

Cutting precision: Precise cutting improves the overall quality and fit.

Seam types: Select seam types that enhance strength and appearance.

Measurement points for fit: Focus on waist, hips, and inseam to achieve a proper fit.

Tip: Create a detailed tech pack with all measurements, materials, and finishing details. This document helps manufacturers understand your expectations and reduces errors.

Determine Quality Standards and Compliance

You must set clear quality standards before you begin production. Quality standards guide manufacturers and help you maintain consistency. International certifications show that your products meet global requirements and reassure your customers about safety and ethical practices.

Below is a table of important certifications for jeans manufacturing in China:

Certification Standard | Description |

|---|---|

BSCI | Ensures ethical manufacturing practices |

ISO | Focuses on quality management systems |

OEKO-TEX® Standard 100 | Confirms product safety |

Ask your supplier for proof of these certifications. Reliable manufacturers will share documentation and explain their compliance processes. You should also check if they follow local regulations for denim production.

Note: Regular audits and sample testing help you maintain high quality throughout your supply chain.

Research China Jeans Manufacturers

Use Online Platforms and Sourcing Agents

You can start your search for china jeans manufacturers by exploring online platforms like Alibaba, Made-in-China, and Global Sources. These directories let you filter suppliers by product type, location, and certifications. Sourcing agents also play a key role in finding reliable jeans manufacturers in China. They use their industry knowledge and networks to connect you with trustworthy suppliers. Sourcing agents save you time by handling vetting and negotiations. They help bridge language gaps and verify manufacturer credentials. You gain access to a wider range of denim suppliers, which increases your options.

Sourcing agents leverage industry connections to find reliable manufacturers.

They handle negotiations and vetting, saving you time.

They help overcome language barriers.

They verify credentials for trustworthiness.

They provide access to many suppliers.

Tip: Always check if the sourcing agent has experience with denim and jeans production. This ensures they understand your quality standards.

Check Location, Specialization, and Scale

You should look at where the manufacturer operates. Many leading china jeans manufacturers are based in Guangdong, Zhejiang, and Jiangsu provinces. These regions have strong denim production hubs. You need to check if the manufacturer specializes in jeans or offers a wide range of denim products. Specialization often means better quality and consistency. You should also consider the scale of operation. Large factories can handle big orders, while smaller specialized factories offer flexibility for custom jeans.

Manufacturer Type | Minimum Order Size |

|---|---|

Large Factories | 1000+ pieces |

Smaller Specialized Factories | 100-500 pieces |

Note: Choose a manufacturer whose scale matches your business needs. This helps you avoid delays and ensures reliable supply.

Review Client Testimonials and Case Studies

You need to review client testimonials and case studies before making a decision. Testimonials show how other brands rate the reliability and quality of the manufacturer. Case studies reveal how manufacturers solve problems and adapt to global trends. They also highlight strengths like innovation and technical depth.

Insight Type | Description |

|---|---|

Quality | Successful manufacturers showcase high-quality production standards. |

Innovation | They adopt modern practices to enhance product offerings. |

Adaptability | Manufacturers demonstrate flexibility in meeting global demands. |

Cultural Relevance | Manufacturers align their products with consumer trends. |

Technical Depth | They possess the expertise needed for complex production processes. |

Manufacturer | Key Strengths |

|---|---|

China Jeans Co. | Blends traditional techniques with modern practices, achieving international acclaim for quality. |

Tip: Look for case studies that show how the manufacturer meets quality standards and adapts to new denim trends. This helps you judge their reliability.

Evaluate Jeans Manufacturers in China

Assess Production Capacity and Technology

You need to check the production capacity of jeans manufacturers in China before you make any decisions. Reliable suppliers can handle your order size, meet deadlines, and offer flexibility for custom designs. When you evaluate production capacity, look for these benchmarks:

Minimum order quantity (MOQ)

Customization capabilities

Turnaround time for samples and bulk orders

Sustainability practices

Scale of production

OEM/ODM flexibility

Advanced technology plays a big role in quality and efficiency. Top factories use high-tech looms and modern equipment to produce denim. You should ask about their machinery and digital systems. The table below shows common technologies used by leading manufacturers:

Technology | Description |

|---|---|

Digital Pattern Management | Ensures consistency in fit and finish across large production runs. |

Laser Cutting | Provides precision in cutting denim, reducing waste and improving efficiency. |

Automatic Defect Detection | Utilizes automation to identify defects in fabric, enhancing quality control. |

Enzyme Washing Systems | Reduces water and chemical usage while achieving soft, vintage textures. |

Ozone Treatments | Creates faded effects without harsh chemicals, aligning with environmental standards. |

AI-Powered Fabric Inspection | Enhances quality assurance by inspecting fabric for defects before production. |

ERP-Integrated Production Tracking | Allows for real-time tracking of production processes, improving efficiency and transparency. |

On-Site Water Recycling Plants | Supports sustainable manufacturing practices by recycling water used in production. |

Tip: Ask for a factory tour or video demonstration. This helps you see their technology and workflow in action.

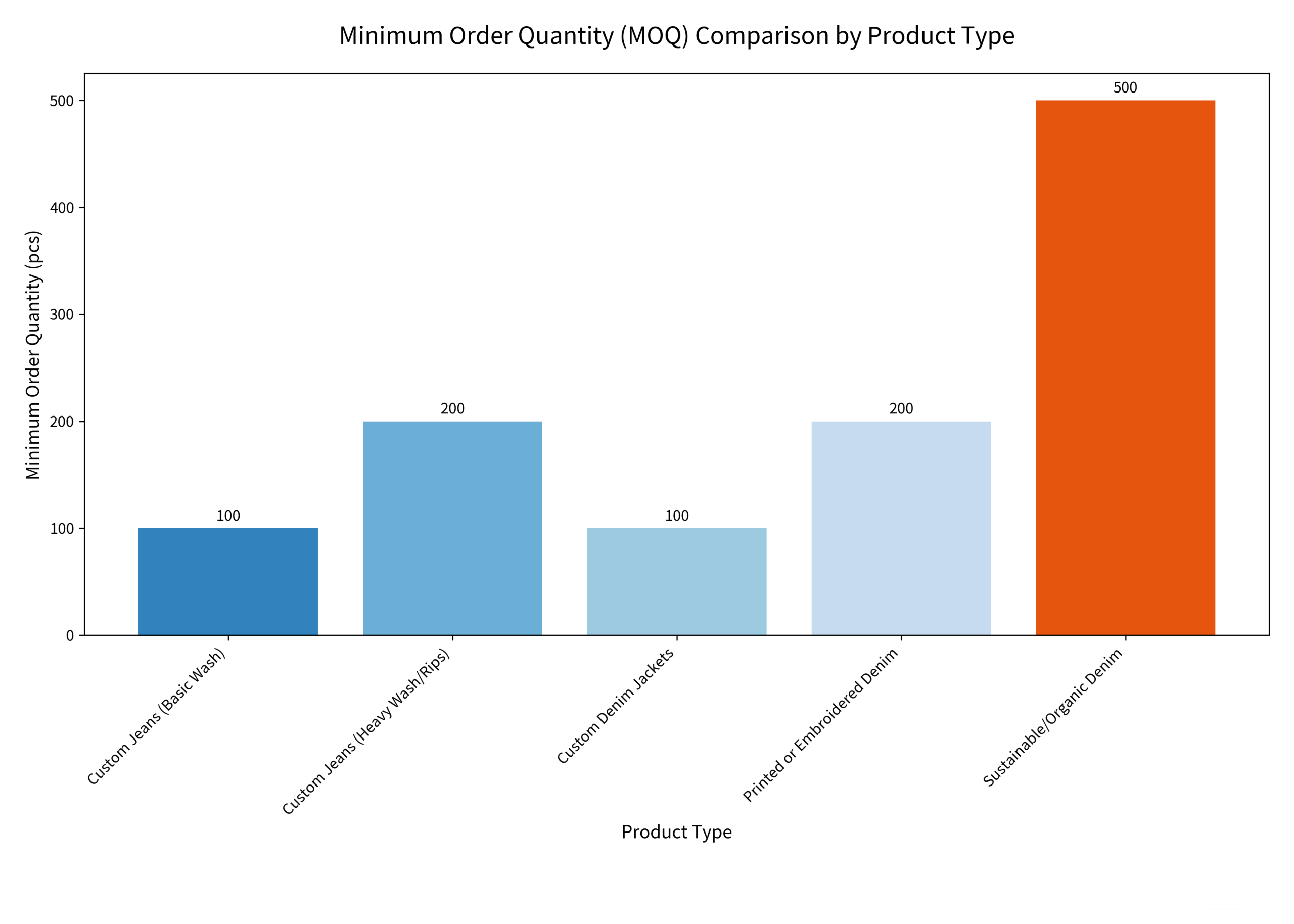

Review Customization and MOQ

Customization options let you create unique denim products for your target market. You should ask about the manufacturer’s ability to handle special washes, embroidery, or sustainable materials. Minimum order quantity (MOQ) is another key factor. It affects your budget and inventory planning. The table below shows typical MOQ ranges for different denim products:

Product Type | Standard MOQ Range |

|---|---|

Custom jeans (basic wash) | 100 pcs per style |

Custom jeans (heavy wash/rips) | 100-200 pcs per style |

Custom denim jackets | 100 pcs |

Printed or embroidered denim | 100-200 pcs |

Sustainable/organic denim | 500 pcs+ |

Tip: Choose a manufacturer with flexible MOQ policies. This helps you test new styles without large upfront costs.

Inspect Quality Control Processes

Quality control is the backbone of reliable jeans production. You should ask about the factory’s inspection routines and testing standards. Reputable china jeans manufacturers use several layers of checks to maintain quality. The table below outlines standard quality control processes:

Quality Control Process | Description |

|---|---|

Sample Check | Evaluate initial samples to verify fabric, construction, appearance, and functional details. |

Production Monitoring | On-site monitoring throughout production to detect early issues and ensure workflow stability. |

During Production Inspection | Conducted when at least 10% of products are finished to catch early defects and improve final quality. |

Pre-Shipment Inspection | Final check to verify product quality, specifications, packaging, quantities, and labeling. |

Container Loading Supervision | Monitor loading to ensure products are correctly packed and shipped in proper condition. |

Laboratory Testing | Includes tests for fabric stregth and |

Reliable jeans manufacturers in China use durable materials and precise stitching techniques. They also integrate sustainable practices like waterless dyeing and recycled denim. These steps help ensure consistent quality across every batch.

Note: Regular inspections and lab tests help you catch problems early and maintain high standards.

Request Samples and Quality Checks

Analyze Sample Quality

You should always request samples before placing a bulk order with jeans manufacturers in china. Samples help you check if the denim matches your brand’s standards and if the supplier understands your requirements. When you ask for samples, provide a detailed tech pack, sketches, and a bill of materials. This helps the manufacturer deliver exactly what you expect. Include a brand cover letter and set clear deadlines. Mood boards can also help align your vision with the supplier.

Here are best practices for requesting and evaluating samples:

Best Practice | Description |

|---|---|

Clear Communication | Specify product model, material, color, and features to reduce miscommunication. |

Evaluation of Samples | Use samples to verify quality and specifications, lowering risks for bulk orders. |

Discuss Costs | Clarify sample production and shipping fees; negotiate if you plan a large order. |

Provide Detailed Specifications | Include tech pack, BOM, and customization preferences to ensure the sample meets your needs. |

Tip: Request detailed product specifications and discuss sample costs upfront. Negotiate fees if you plan to order in bulk.

Test Materials and Workmanship

You need to test the materials and workmanship of the denim sample. Start with a visual inspection. Look for fabric composition, weight, weave quality, and color uniformity. Touch the fabric to check thickness, density, texture, and elasticity. Reliable jeans manufacturers in china use long-staple cotton and ring-spun yarns for durability. Check the dye quality to make sure the indigo color does not fade quickly.

Use the table below to guide your assessment:

Test Type | Description |

|---|---|

Yarn Quality | Long-staple cotton and ring-spun yarns offer strength and texture. |

Dye Quality | Even penetration and good colorfastness prevent excessive fading. |

Weaving Techniques | Selvedge denim shows higher craftsmanship. |

Finishing Processes | Sanforization controls shrinkage; washing techniques affect texture. |

Durability Testing | Abrasion resistance and tear strength tests show real-world performance. |

Craftsmanship | Inspect stitching, hardware durability, and finishing details. |

Note: Testing materials and workmanship helps you avoid costly mistakes and ensures your jeans meet your quality standards. Careful sample evaluation is a key step in successful sourcing.

Negotiate Pricing and Terms

Understand Pricing Structure and MOQ

You need to understand how pricing works when you negotiate with jeans manufacturers in China. Factories often set prices based on your order size and the level of customization you request. Larger orders usually mean lower costs per unit because factories can spread setup costs over more pieces. Custom designs or special washes increase costs, especially if you order fewer jeans. Most china jeans manufacturers set minimum order quantities between 500 and 3,000 pieces per style. If you want fully custom denim, you may need to start at 1,000 pieces per wash or style. Smaller orders, such as those below 300 pieces, often come with higher prices per unit. For example, a Canadian startup reduced its cost per unit from $19 to $11.30 by increasing its order from 200 to 1,500 units.

Larger orders lower your per-unit cost.

Customization increases costs, especially for small orders.

Typical factory MOQs range from 500 to 3,000 pieces per style.

Small orders below 300 pieces often cost more per unit.

Discuss Payment Terms and Contracts

You should always clarify payment terms before you finalize any agreement. Most jeans manufacturers in China require a deposit when you place your order. The balance is usually due after shipment, based on the bill of lading. Some factories offer open account terms for established clients, which allow you to pay the balance within 30 to 60 days after shipment. Use a clear contract to protect your interests and outline all terms.

Payment Term | Description |

|---|---|

30% Deposit, Balance Due After B/L | Pay 30% upfront, settle the rest after shipping with bill of lading. |

Open Account (O/A) Terms | For trusted clients, pay balance 30-60 days after shipment. |

Tip: Always review contracts carefully and confirm payment schedules before you start production.

Clarify Turnaround Time and Hidden Costs

You need to ask about turnaround times for samples and bulk orders. Reliable jeans manufacturers in China will give you clear timelines for each stage. Hidden costs can affect your budget quickly. Watch for shipping fees, tariffs, sample charges, and quality control checks. Currency exchange rates and communication delays may also impact your final cost. Tariffs can increase costs for small brands, sometimes forcing you to adjust your sourcing strategy or consider local production.

Shipping costs and tariffs can change your total price.

Sample fees and quality checks add to your expenses.

Currency exchange rates and communication delays may affect your budget.

Minimum order quantities can influence your overall cost.

Note: Always request a detailed cost breakdown and confirm all fees before you sign any agreement.

Review Logistics and Compliance

Confirm Lead Times and Shipping Options

You need to understand how long it takes to produce and ship jeans from China. Lead times can vary based on your order type and shipping method. Stocked goods ship in just one day, while made-to-order jeans may take up to 60 days. Private label production often requires 8 to 24 weeks, depending on factory workload and material availability.

Here is a table showing average lead times for each stage:

Stage | Lead Time (Days) |

|---|---|

Order to Export (China) | 30–44 |

Ocean Transit (Shanghai to LA) | 20–30 |

U.S. Import and Distribution | 7–19 |

You have several shipping options for jeans. Express door-to-door delivery works best for urgent shipments, with delivery in 1–3 days. Air shipping moves goods quickly but costs more, ranging from $5 to $65 per kilogram. Ocean freight offers a cost-effective solution for large orders, though it takes longer and may face port delays. Ground shipping suits nearby countries but is less common for international jeans orders.

Express shipping: Fast, reliable, 1–3 days

Air shipping: Quick, expensive, best for small urgent orders

Ocean freight: Economical for bulk, slower, possible delays

Ground shipping: Limited to neighboring regions

Tip: Compare freight forwarders and check their reputation. Accurate weighing and proper paperwork help you avoid extra charges.

Ensure Export and Import Compliance

You must follow export and import rules to avoid delays and penalties. Jeans manufacturers in China need to meet product quality standards set by importing countries. Labels must show country of origin, fiber content, care instructions, size, and safety warnings. Factories must keep jeans free from banned chemicals like formaldehyde and azo dyes. Compliance rules can change by region, so always check the latest requirements.

Compliance Aspect | Details |

|---|---|

Product Quality | Jeans must meet the quality standards of the destination country. |

Labeling Requirements | Labels must include origin, fiber content, care instructions, size, and safety warnings. |

Chemical Safety and Hazardous Substances | Jeans must not contain banned chemicals such as formaldehyde or azo dyes. |

Note: Work with your supplier to review all documents and certifications before shipping. This step protects your brand and ensures smooth customs clearance.

Manage Communication and Relationships

Set Clear Communication Channels

You need to set up clear communication channels when working with jeans manufacturers in China. Good communication helps you avoid mistakes and keeps your project on track. You can use different methods to stay connected and share updates. Each method has its own purpose and benefit.

Communication Method | Purpose |

|---|---|

For formal communication and documentation. | |

Instant messaging apps | For quick, real-time communication. |

Regular video calls | To maintain personal connections and clarity. |

Shared production schedules | To align timelines and expectations. |

You should appoint a dedicated project manager to handle daily communication. This person keeps everyone informed and solves problems quickly. A bilingual liaison helps bridge language gaps and makes sure both sides understand each other. Proactive communication helps you avoid misunderstandings and keeps your production running smoothly.

Appoint a dedicated project manager.

Use a bilingual liaison to bridge language gaps.

Ensure proactive communication to avoid misunderstandings.

Tip: Schedule regular video calls to discuss progress and address any issues early. This builds trust and keeps your project moving forward.

Build Trust and Long-Term Partnership

Building trust with your jeans manufacturer leads to better results and long-term success. You need to invest time in creating a strong relationship. When you show respect and communicate openly, your supplier feels valued and works harder for your brand. Regular communication helps you solve problems and adapt to changes quickly.

Fostering relationships with suppliers is vital for long-term partnerships.

Trust-building contributes significantly to the success of the business relationship.

Establish a strong relationship with suppliers to secure better terms and flexible arrangements.

Regular communication and mutual respect are essential for a successful partnership.

Invest time in building trust and mutual understanding with Chinese jeans suppliers.

Effective communication is crucial for a sustainable business relationship.

You can secure better terms and flexible arrangements when you build a strong partnership. Mutual respect and understanding help you overcome challenges together. When you invest in trust, you create a foundation for growth and stability.

Note: Treat your supplier as a partner, not just a vendor. This mindset encourages loyalty and leads to better quality and service over time.

Final Selection and Ongoing Monitoring

Make Final Decision

You have reached the final step in choosing a jeans manufacturer in China. At this stage, you need to compare all the options and select the partner that best fits your business goals. Focus on several important criteria to make a smart choice:

Check the quality of the jeans to ensure every piece meets your standards.

Review customization options so you can create unique denim styles for your brand.

Evaluate production capabilities to confirm the manufacturer can handle your order volume and maintain quality.

Assess sustainability practices to align with modern consumer expectations for eco-friendly denim.

Look for consistent quality across all batches to keep your customers satisfied.

Consider competitive pricing, but make sure it does not come at the expense of quality or customization.

You should create a simple comparison table to help organize your findings:

Criteria | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

Quality | ✅ | ✅ | ❌ |

Customization | ✅ | ❌ | ✅ |

Production Scale | ✅ | ✅ | ✅ |

Sustainability | ✅ | ❌ | ✅ |

Pricing | ✅ | ✅ | ✅ |

Tip: Choose the manufacturer that scores highest in the areas most important to your brand.

Implement Quality Control and Feedback

After you select your jeans manufacturer in China, you need to set up strong quality control and feedback systems. These steps help you maintain high standards and build trust with your supplier. Use unbiased and transparent inspections, such as third-party checks, to make sure the manufacturer follows your requirements. Early detection of defects helps you fix problems before they reach your customers. This process keeps your denim products reliable and consistent.

Regular inspections encourage china jeans manufacturers to stay accountable. When they know you will check their work, they pay closer attention to detail. You should share feedback after each shipment. This helps the manufacturer improve and adapt to your needs. Over time, these actions strengthen your partnership and support long-term success.

Use third-party inspectors for objective results.

Detect and prevent defects early in production.

Hold manufacturers accountable for quality standards.

Share feedback to encourage improvement.

Note: Ongoing monitoring protects your brand and ensures your jeans always meet customer expectations.

You can choose reliable jeans manufacturers in China by following clear steps. The table below highlights important criteria:

Criteria | Description |

|---|---|

Manufacturing capacity | Check if the factory meets your order needs. |

Product quality | Request samples and inspect details. |

Certifications | Look for BSCI, ISO9001, or WRAP compliance. |

Customization ability | Confirm options for design and labeling. |

Communication | Assess responsiveness and transparency. |

Expert resources offer guidance on technical sketches, sourcing materials, and quality assurance. Start your sourcing journey today and build strong partnerships for your brand’s growth.

FAQ

How do you verify a jeans manufacturer’s credibility in China?

You can check business licenses, certifications, and client reviews. Ask for references from past customers. Use sourcing platforms with verified suppliers. Request factory audit reports for extra assurance.

What is the typical minimum order quantity (MOQ) for custom jeans?

Most manufacturers set MOQs between 50 and 1,000 pieces per style. You should confirm the MOQ before placing an order. Flexible MOQs help you test new designs.

How can you ensure product quality before bulk production?

You should request samples and conduct material tests. Inspect stitching and finishing. Use third-party quality checks. Share feedback with the manufacturer after each shipment.

What payment terms do Chinese jeans manufacturers usually offer?

Most suppliers ask for a 30% deposit and the balance after shipment. Some offer open account terms for trusted clients. Always review contracts and confirm payment schedules.