Low moq gives you a smart way to launch your denim clothing brand. You can test new designs with less risk and avoid tying up your cash in unsold inventory. A low moq policy lets you manage your clothing line with greater control and respond quickly to what your customers want. Use this approach to keep your business flexible and ready to grow.

Key Takeaways

Low MOQ allows you to launch your denim brand with less financial risk. Test new designs without tying up cash in unsold inventory.

Small-batch and on-demand production models help you stay flexible. Quickly respond to customer trends and reduce waste.

Efficient inventory management is easier with low MOQ. Produce only what you need, allowing for faster launches and better cash flow.

Building strong relationships with manufacturers is crucial. Clear communication and trust lead to better production outcomes.

Negotiating MOQ and pricing can lower your costs. Explore sliding-scale pricing to make small orders more affordable.

Low MOQ in Denim

What Is Minimum Order Quantity

Minimum order quantity means the smallest number of clothing units a supplier will produce in one run. In denim manufacturing, this concept shapes your business decisions. You must understand how minimum order quantities affect production efficiency, material sourcing, and pricing. Suppliers set moq requirements based on factors like fabric sourcing, trims, dyeing, and washing needs. For example, if you need 150 kg of fabric for a batch of jeans but the supplier’s moq requirements start at 500 kg, you face extra costs or must adjust your order. You should always ask about minimum order quantity before starting production.

Tip: Always clarify minimum order quantities with your supplier to avoid unexpected costs.

Typical MOQ Ranges for Denim Brands

You will find that minimum order quantities for denim clothing vary by product type and manufacturer. Jeans often require 200–500 pieces per style, while t-shirts need 50–200 pieces. Custom denim usually comes with moq ranging from 500–2,000 pieces per style. OEM partners may offer lower moq, around 500–1,000 pieces, but ODMs often require 1,000–2,000 pieces. The minimum order quantity depends on fabric choice, design complexity, order volume, factory location, and compliance needs. For premium selvedge denim, moq can be as low as 500–1,000 yards because of specialized production.

Factors influencing minimum order quantities:

Fabric weight and origin

Dye method

Number of pieces and trims

Wash treatments

Factory location

Compliance requirements

Small-Batch and On-Demand Models

Small-batch and on-demand production models help you manage minimum order quantities and keep your clothing line flexible. Small-batch manufacturing uses fast sampling cycles and rapid prototyping. You can produce smaller runs and test new styles quickly. On-demand models, like those used by Shein, rely on digital systems to measure demand and adjust production in real time. These models reduce waste and keep unsold inventory low. You benefit from sustainability, lower water and energy use, and less chemical waste. Technologies such as low-liquor dyeing, ozone finishing, and digital printing support these efficient processes.

Note: Small-batch and on-demand models let you test new clothing styles and respond to trends without committing to high minimum order quantities.

Benefits of Lower Minimum Quantities

Reduced Financial Risk

You can lower your financial risk by choosing low moq for your denim clothing line. When you order smaller batches, you avoid the danger of overproduction. Traditional bulk production often forces you to invest a large amount of money upfront. If your clothing does not sell, you may face serious financial problems. By producing only what you need, you keep your budget safe and avoid tying up cash in unsold inventory. This approach lets you use your resources for other important areas, such as marketing or developing new samples. Lower minimum quantities also help you stay agile and ready to adjust your strategies as the market changes.

Tip: Always match your production runs to real demand. This keeps your cost under control and protects your business from unexpected losses.

Flexibility and Fast Market Testing

Low moq gives you the power to test new clothing styles quickly. You can launch small runs of jeans or jackets and see how customers respond. This flexibility helps you spot trends early and adapt your designs before making a big investment. Many brands use this strategy to stay ahead of the competition and keep their collections fresh.

Evidence Description | Details |

|---|---|

Experimentation Capability | Brands can launch new styles with MOQs as low as 30 pieces, enabling them to test various washes, fits, and finishes without significant financial commitment. |

Agility in Design | The ability to pivot quickly when trends shift is facilitated by tiered pricing and rush-order options, keeping inventory fresh and responsive to market demands. |

You can use flexible manufacturing solutions to produce samples and small batches. This lets you gather feedback and make changes fast. When you see a style gaining popularity, you can scale up production with confidence. These strategies help you avoid the cost of large, risky orders and keep your clothing line in sync with what your customers want.

Efficient Inventory Management

Lower minimum quantities make inventory management easier for denim startups. You can produce as few as 20–50 pieces per style, which is perfect for testing new designs or limited drops. This small batch flexibility means you do not have to worry about storing large amounts of unsold clothing. You can also launch new products faster because you do not wait for big orders to finish.

Small batch flexibility lets you test new clothing designs without high cost.

You keep your risk low and your budget balanced.

Faster launches help you respond to trends and customer feedback.

You can introduce multiple designs at once without spending too much.

Market testing becomes easier, so you know what works before scaling up.

Cash flow management improves because you do not tie up money in excess inventory.

Some denim manufacturers offer moq as low as 30 pieces for each order. This is ideal for micro-drop testing and helps you stay competitive. By using these strategies, you can keep your inventory lean and your business ready to grow.

Note: Lowering moq leads to reduced upfront cost and minimizes inventory risks. These factors are essential for maintaining cash flow, especially for new denim brands.

You can see that low moq and lower minimum quantities give you more control over your clothing business. You can manage cost, test samples, and scale up when you see demand. These strategies help you build a strong foundation for your brand.

Finding Minimum Order Quantity Manufacturers

Researching Low MOQ Partners

You need to find the right manufacturer to support your clothing brand’s growth. Start by using word of mouth and industry networks. Many successful brands discover reliable manufacturing partners through recommendations from other designers or by joining fashion manufacturing forums. You can also attend trade shows like MAGIC Las Vegas, Texworld USA, and Sourcing at MAGIC. These events connect you with emerging clothing manufacturers and established suppliers who offer low moq options. Online platforms such as Alibaba and Global Sources help you compare clothing manufacturers by moq, quality standards, and customization options. Always check if the manufacturer provides customized manufacturing solutions, including washes and embroidery, and if they support small runs like 30 pieces per style.

Consider these factors when researching:

Quality standards and certifications

Minimum order quantities for each style

Customization capabilities

Sustainability practices

For smaller brands, partnering with a low moq clothing manufacturer can be crucial for competitiveness in the fashion manufacturing industry.

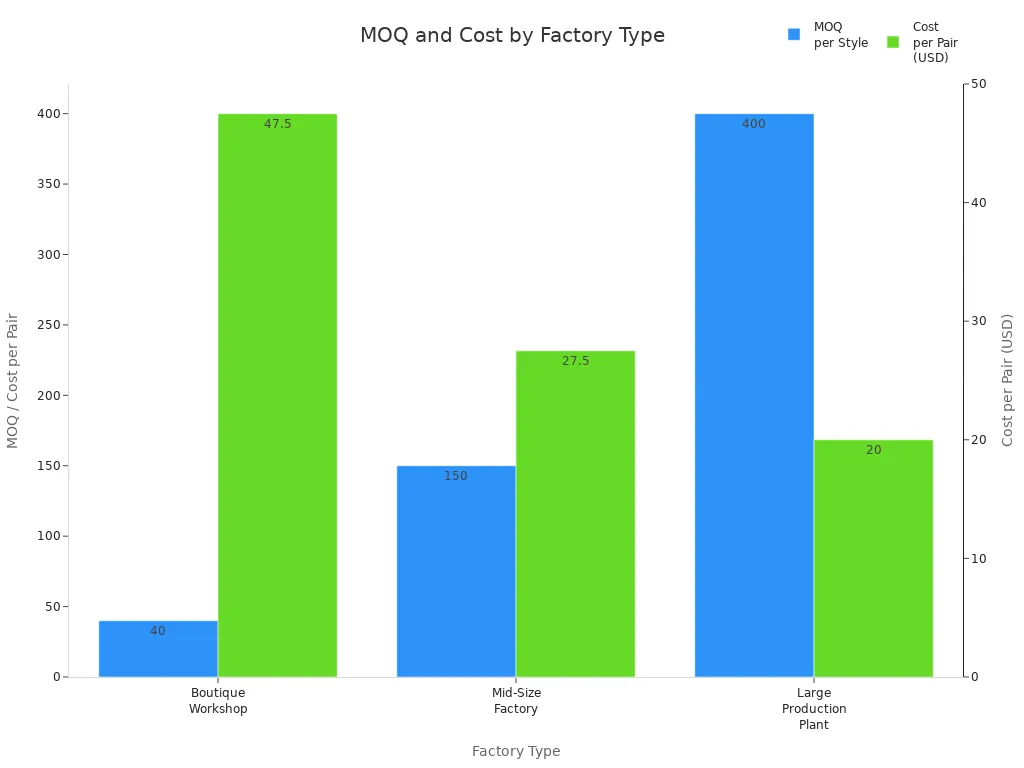

Negotiating MOQ and Pricing

Negotiation is a key part of fashion manufacturing. You should understand that lower moq often means higher per-unit costs. Factories may offer a sliding-scale pricing model. For example, boutique workshops may set moq at 30–50 pieces with costs of $35–$60 per pair, while large plants may require 300–500 pieces at $15–$25 per pair. Many mid-size factories will reduce moq by 5–10% if you accept a 5–10% premium per unit.

Factory Type | MOQ per Style | Cost per Pair (USD) |

|---|---|---|

Boutique Workshop | 30–50 | $35–$60 |

Mid‑Size Factory | 100–200 | $20–$35 |

Large Production Plant | 300–500 | $15–$25 |

You can often negotiate better terms by agreeing to bulk fabric purchases or by showing a commitment to future orders. This approach supports streamlined manufacturing processes and helps you build an efficient supply chain.

Building Manufacturer Relationships

Building strong relationships with your manufacturer is essential for a dynamic supply chain. Treat your manufacturer as a partner. Visit your key suppliers in person, meet at trade shows, or use video tours to build trust. Keep communication consistent, even when you do not have active orders. Align on values like sustainability and ethical production. Work together to solve problems and maintain transparency about your expectations and limitations. When working with manufacturers in Asia, always clarify your requirements. Specify fabric type, composition, weight, width, color, and intended usage. Provide fabric swatches or photos to ensure accurate clothing manufacture moq and style replication. This attention to detail leads to an efficient supply chain and long-term success in fashion manufacturing.

Overcoming Low MOQ Challenges

Managing Higher Per-Unit Costs

You may notice that ordering small batches of clothing often leads to higher per-unit costs. Factories charge more for low moq because they spend extra time setting up machines and sourcing materials for smaller runs. You can offset these costs by using smart strategies:

Negotiate moq with your supplier to lower your initial investment.

Tie material purchases strictly to confirmed client orders so you avoid excess inventory.

Avoid overstocking specialty trims at the start to keep your cash flow healthy.

Tip: Ask your supplier about sliding-scale pricing. This lets you pay less per unit as your order size increases.

Ensuring Consistent Quality

Maintaining high quality in small-batch clothing production requires careful planning. You should choose superior denim materials and work with manufacturers who test quality at every step. Clear communication about production schedules and lead times helps you avoid delays. Automated processes can also raise output speeds and keep product quality consistent.

Facilities with advanced machinery handle complex designs and fabrics with precision. Skilled teams execute every step, from pattern making to final stitching, to maintain high standards. Dedicated quality control teams inspect each batch to catch and fix problems early.

Here is a typical quality control process for small-batch denim clothing:

Step Number | Quality Control Process | Description |

|---|---|---|

1 | Fabric Inspection | Examines fabric for defects before production begins. |

2 | Cutting Inspection | Verifies accuracy in cutting to ensure dimensional correctness. |

3 | In-Process Inspection (Inline) | Monitors quality during production to catch issues early. |

4 | End-Line Inspection | Comprehensive review of appearance and workmanship before finishing. |

5 | Finishing Inspection | Checks final touches like thread trimming and packaging quality. |

6 | Measurement Inspection (FRI) | Measures garments against specifications to ensure proper fit. |

7 | Final Random Inspection (FRI) | Last check on overall quality and packing before shipment. |

Scaling Up Production

As demand for your clothing grows, you must scale up production without losing control over quality or costs. You may face challenges such as higher labor expenses, strict moq limits, and difficulty sourcing specialized materials. To overcome these issues, use best practices that support growth:

Local manufacturing helps you produce clothing closer to your customers, reducing lead times and transportation costs.

Flexible production models allow you to adjust batch sizes and respond quickly to market changes.

Lean production techniques improve efficiency and help you meet larger moq requirements.

Quality assurance standards, such as AQL 2.5 inspections, keep your products consistent as you scale.

Social responsibility audits, like BSCI, show your commitment to ethical clothing production.

Note: Scaling up from low moq to larger runs requires planning and strong supplier relationships. Stay focused on quality and efficiency as your brand grows.

You can unlock real growth for your denim brand by using low moq. This approach gives you flexibility, reduces risk, and lets you test new ideas. See how startups benefit:

Benefit | Description |

|---|---|

Flexibility in order sizes | Adjust production to match demand |

Reduced risk of excess stock | Avoid unsold inventory |

Professional quality | Maintain high standards in small batches |

Lower upfront costs | Start with less financial pressure |

Market testing ability | Try new designs before large commitments |

You should partner with the right manufacturer, plan ahead, and focus on clear communication. Take the next step and build your denim business with confidence.

FAQ

What does MOQ mean for a denim startup?

MOQ stands for Minimum Order Quantity. You must order at least this number of pieces from a manufacturer. Low MOQ helps you test new ideas and manage your budget.

Can you negotiate MOQ with manufacturers?

Yes, you can often negotiate MOQ. You should ask about sliding-scale pricing or offer to buy more fabric in exchange for a lower MOQ. Good communication helps you find flexible solutions.

How does low MOQ affect your costs?

Low MOQ usually means higher cost per piece. You pay more for each item because the factory spends extra time on small batches. You can balance this by testing designs and avoiding unsold stock.

What is the best way to find low MOQ denim suppliers?

You can search online platforms, attend trade shows, or ask for recommendations from other brands. Always check reviews and request samples before you commit to a supplier.

Does low MOQ help with sustainability?

Yes! Low MOQ lets you produce only what you need. You reduce waste, save resources, and avoid overproduction. This approach supports a more sustainable denim business.