If you run a small brand and want the best value from a denim manufacturer for small brands, you probably weigh cost, quality, and flexibility. Many brands look to Asia for denim production, drawn by lower prices and more options, even as tariffs make things tricky. Here’s what’s happening:

Most brands stick with Asian denim, even with higher tariffs, because American production faces labor shortages, high costs, and weak infrastructure.

Only 17% of brands plan to boost American denim sourcing this year.

The premium denim market keeps growing fast, with a value of $28.64 billion in 2024 and strong demand for both Japanese and American denim culture.

You’ll see American denim still shines for craftsmanship and heritage, while Asian mills offer more flexibility and cost savings.

Key Takeaways

Consider production costs carefully. Asian manufacturers often provide lower costs due to cheaper labor, while American options focus on quality and ethical sourcing.

Be aware of hidden expenses. Always ask your manufacturer about potential fees like quality control checks and sample costs to avoid surprises.

Flexibility is key for small brands. Both American and Asian manufacturers offer low minimum order quantities, allowing you to test new designs without a large upfront investment.

Prioritize communication. Choose manufacturers who understand your needs and can provide quick responses to keep your project on track.

Focus on sustainability. Select denim partners who use eco-friendly practices and prioritize fair labor to build a brand that resonates with conscious consumers.

Cost Factors for Denim Manufacturer for Small Brands

Production Costs USA vs. Asia

When you look for a denim manufacturer for small brands, cost is usually the first thing you check. You want to know if making jeans in the USA or Asia will save you money or give you better quality. Let’s break it down with a simple table:

Region | Key Factors Affecting Cost | |

|---|---|---|

USA | Higher | Shorter lead times, quality standards, ethical sourcing |

Asia (China, Vietnam, Bangladesh) | Lower | Lower labor costs, optimized production processes |

You’ll notice that Asian factories offer lower costs per unit. They use efficient production methods and pay less for labor. That’s why Southeast Asia supplied about 72.83% of U.S. apparel imports in 2024. If you want premium positioning or ethical sourcing, you might lean toward U.S. or European manufacturers. They focus more on quality and responsible practices, especially with raw selvedge denim and selvedge jeans.

Panther Denim’s recent expansion in Asia shows how competitive the region has become. Asian mills now offer advanced technology and flexible options for small brands. You get more choices for raw selvedge denim, and you can order smaller batches without breaking the bank. If you’re just starting out, this flexibility can help you test the market and grow your brand.

Shipping, Tariffs, and Fees

Shipping costs and tariffs can change your total price fast. If you work with a jeans manufacturer in Asia, you pay less for production, but you need to factor in extra fees. Tariffs, especially those from the Trump era, can raise your costs and make your jeans less affordable for customers.

Here’s what you need to watch for:

Tariffs can increase costs for brands, which may lead to higher prices for consumers.

Small brands may need to shift their supply chains or invest in local production to mitigate these costs.

Specific tariffs imposed on imports from various countries can significantly affect the total cost for small brands sourcing denim.

You might think about switching to a denim manufacturer for small brands in the USA to avoid tariffs. But keep in mind, American production costs are higher. You need to balance shipping fees, customs charges, and the risk of delays. If you want to sell raw selvedge denim or selvedge jeans at a competitive price, these extra costs matter.

Hidden Expenses

Hidden expenses can sneak up on you. When you work with a jeans manufacturer overseas, you might face unexpected costs. These can include:

Quality control checks

Sample fees

Communication delays

Currency exchange rates

You also need to think about minimum order quantities. Some Asian mills offer low MOQs, but others require you to buy in bulk. If you want to launch a small batch of selvedge jeans, you need to ask about these details upfront.

American denim manufacturers sometimes charge more for setup and sampling. They may offer better support and faster turnaround, but you pay for those perks. If you want to build a brand around raw selvedge denim, you need to budget for these hidden costs.

Tip: Always ask your denim manufacturer for small brands about all possible fees before you sign a contract. This helps you avoid surprises and keeps your budget on track.

You can see that choosing the right jeans manufacturer is not just about the sticker price. You need to look at production costs, shipping, tariffs, and hidden fees. If you want to stand out with selvedge denim, you need to plan for every expense.

Quality: American Selvedge Denim vs. Asian Options

Fabric and Craftsmanship

When you look for the best denim for your brand, you want fabric and craftsmanship that stand out. American selvedge denim has a reputation for durability and style. You see brands like Imogene + Willie, Texas Jeans, Tellason, and Ginew using American cotton and focusing on strong, long-lasting selvedge. These jeans feel sturdy and look classic, perfect if you want your customers to wear them for years.

Asian denim manufacturers offer a wide range of options. You find mass-market choices, but also premium selvedge that rivals American quality. Many Asian mills use advanced technology and efficient production methods. If you want flexibility, you get it here. Some Asian factories can produce small batches of selvedge jeans with custom finishes.

Let’s compare some key differences in fabric quality and craftsmanship:

Category | Levi’s (USA/Asia) | |

|---|---|---|

Fabric Origin | Japan, Italy, Turkey | Turkey, Pakistan, Mexico |

Fit Philosophy | Structured, tech-inspired | Classic, heritage comfort |

Finishing | 3D wash, enzyme-treated | Stonewash, vintage fade |

Sustainability | Water-saving dyeing, Cradle-to-Cradle certified | Recycled cotton, Tencel blends |

Target Market | Premium urban buyers | Heritage and mass premium buyers |

You notice that American selvedge denim focuses on heritage and comfort, while Asian options bring innovation and sustainability. Both regions offer selvedge jeans that appeal to different markets.

Japanese Denim Excellence

If you want the highest level of craftsmanship, you should check out Japanese denim brands. Japanese selvedge denim stands out for its attention to detail and unique finishing processes. Mills in Japan use traditional shuttle looms to create tight, beautiful selvedge edges. You get jeans that feel soft, look rich, and last longer.

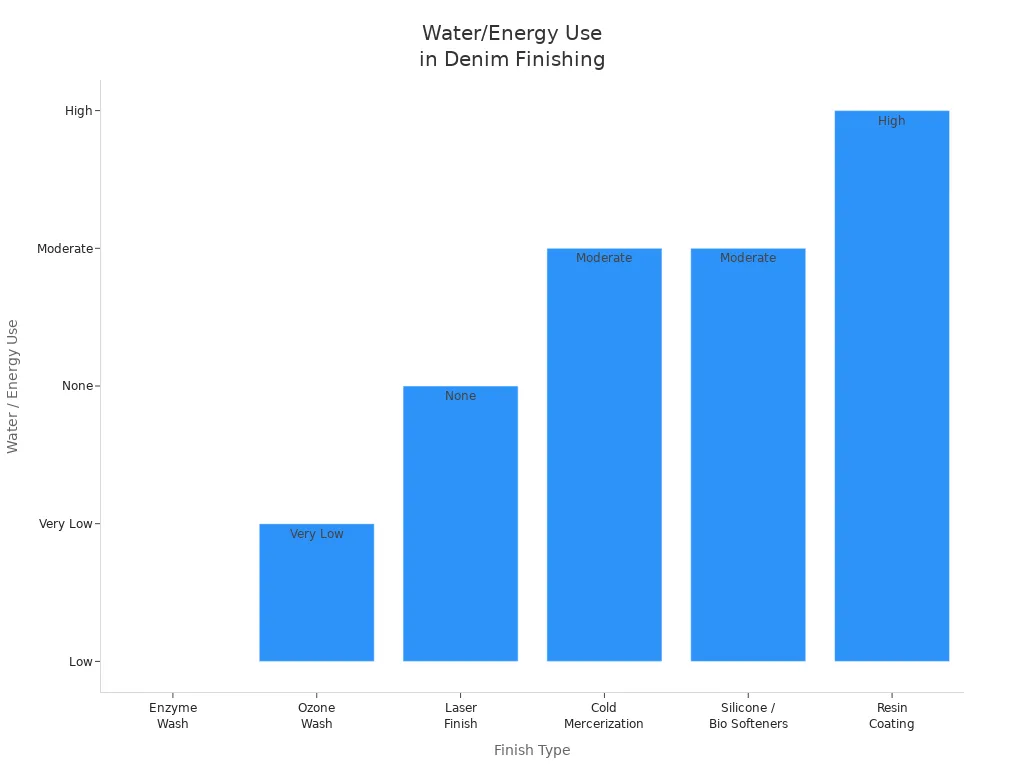

Japanese manufacturers use advanced finishing techniques. Here’s a look at some popular methods:

Finish Type | Process Method | Primary Benefit | Water / Energy Use |

|---|---|---|---|

Enzyme Wash | Biological enzymes break cellulose | Soft touch, controlled fading | Low |

Ozone Wash | O₃ gas oxidizes indigo | Bright blue tone, eco-safe | Very Low |

Laser Finish | Digital light ablation | Vintage texture, zero water | None |

Cold Mercerization | NaOH bath at 20–25°C | Increased dye uptake & luster | Moderate |

Silicone/Bio Softeners | Emulsion-based surface coating | Smooth handfeel, drape | Moderate |

Resin Coating | Polymeric crosslinking | Gloss, wrinkle resistance | High |

You see Japanese denim brands using enzyme and ozone washes to save water and energy. These processes reduce water use by 60% compared to traditional stone or acid washes. You also get 50% less fabric weight loss, which means your selvedge jeans last longer. Japanese mills use 100% biodegradable chemicals, making their denim more eco-friendly.

SzoneierFabrics’ EcoSoft Enzyme Series gives you a 37% increase in surface softness without losing strength. If you want midweight denim shirts that feel comfortable from the first wear, Japanese selvedge denim is a smart choice.

Tip: If you want to build a premium brand, Japanese selvedge denim offers unmatched quality and sustainability. You get beautiful selvedge edges, soft finishes, and eco-friendly production.

Consistency and Reliability

You want your denim manufacturer to deliver consistent quality every time. American selvedge denim makers focus on small-batch production and strict quality control. You get reliable selvedge jeans with strong stitching and classic style. Brands like Tellason and Texas Jeans use American cotton and pay close attention to every detail. You can trust their jeans to last and look good.

Asian manufacturers offer consistency through advanced technology and large-scale production. If you need hundreds of selvedge jeans with the same fit and finish, Asian mills can deliver. Wrangler, for example, produces denim in Bangladesh, Vietnam, and Mexico. They use mass production to keep costs low and quality steady.

Here’s a quick look at how manufacturing practices compare:

Brand | Production Base | Manufacturing Practices |

|---|---|---|

Diesel | Italy, Tunisia, Morocco | Higher labor costs, precise tailoring |

Wrangler | Bangladesh, Vietnam, Mexico | Lower labor costs, mass production |

You get precise tailoring from American and European brands, while Asian mills focus on efficiency and scale. Both regions offer selvedge jeans with reliable quality, but the style and feel may differ.

If you want to create a brand with a story, American selvedge denim gives you heritage and authenticity. If you want flexibility and scale, Asian manufacturers help you grow fast. Japanese selvedge denim stands out for premium quality and eco-friendly processes. You have options for every market and style.

MOQs and Flexibility

USA Manufacturer Minimums

When you start working with an american denim manufacturer, you want to know how many pieces you need to order. Most small brands worry about high minimums, but you actually have options. Some american factories offer lower minimum order quantities (MOQs) than you might expect. Here’s a quick look at what you can expect:

Manufacturer | Minimum Order Quantity (MOQ) |

|---|---|

DiZNEW | |

TEG | 10-50 pieces per style |

You see that some american denim makers let you order as few as 10 pieces per style. This helps you test new selvedge jeans or launch a small collection without a huge upfront investment. If you want to focus on premium selvedge denim, these flexible MOQs make it easier to start small and grow.

Asian Manufacturer Minimums

Asian denim manufacturers also offer attractive MOQs for small brands. You don’t need to commit to massive orders just to get started. Here are some typical minimums:

CreativetTex’s minimum order quantity for jeans manufacturing starts at 100 pieces per design.

Many asian denim mills allow you to mix selvedge styles within your order.

You can often negotiate even lower MOQs if you build a good relationship.

If you want to experiment with different selvedge denim washes or fits, asian manufacturers give you the freedom to do so. You can try out new ideas without risking too much capital.

Flexibility for Small Brands

You want flexibility when you launch a new denim brand. Both american and asian manufacturers understand that small brands need room to grow. You can order small batches of jeans, test new designs, and adjust your strategy as you learn what your customers love.

Tip: Ask your denim manufacturer if you can mix selvedge styles or combine different fits in one order. This helps you offer more choices without raising your costs.

Small MOQs mean you don’t have to overcommit. You can focus on quality, experiment with american selvedge denim, or try innovative asian finishes. This flexibility gives you the power to build your brand your way.

Communication and Support

Language and Time Zones

When you work with a denim manufacturer overseas, you might notice that communication feels different. Time zones can make it tough to get quick answers. Sometimes, you send an email and wait a whole day for a reply. This can slow down your denim project, especially if you need to make changes fast.

Language barriers also play a big role. Not every merchandiser speaks fluent English, and this can lead to misunderstandings. Here are some common challenges you might face:

Merchandisers may have weak communication skills, which makes it hard to explain your denim ideas.

Some manufacturers use very formal language, which can feel awkward and slow down the process.

Traditional business methods, especially in places like Bangladesh, can make it harder to compete with more modern denim factories in China or Vietnam.

If you want to avoid these issues, try to find a denim partner who has experience working with small brands from the U.S. They usually understand what you need and can help you move faster.

Customer Service

Great customer service can make your denim journey much smoother. You want a manufacturer who listens, answers questions, and helps you solve problems. Both American and Asian denim manufacturers offer different strengths. Here’s a quick look at what works best:

Practice | Description |

|---|---|

Supplier Reliability | Partnering with verified suppliers ensures consistent product quality and ethical practices. |

Quality Control | Reliable manufacturers operate vertically integrated facilities, ensuring uniform standards. |

Flexibility in Production | Clear production schedules and flexible capacity help manage order surges effectively. |

Choosing the right denim manufacturer affects your quality and delivery times. Experienced partners know how to build denim that lasts and source materials responsibly. Many small brands now look for manufacturers who care about sustainability. If you pick a denim supplier who uses ethical and eco-friendly practices, your brand can stand out to customers who care about the planet.

Tip: Always ask your denim manufacturer about their customer service team. Quick replies and clear updates can save you time and stress.

Lead Times and Logistics

Production Timelines

You want your denim to arrive on time. Production timelines can make or break your launch. If you choose a manufacturer in the USA, you often see faster turnaround. Many American denim factories finish small orders in 4 to 8 weeks. You get updates quickly, and you can visit the factory if you need to check on your denim.

Asian denim manufacturers usually need more time. Most factories in Asia take 8 to 12 weeks for production. Sometimes, it takes longer if you order custom denim or special finishes. You might wait for fabric to arrive or for your spot in the production line. If you plan ahead, you can avoid stress. Always ask your denim partner for a clear timeline before you start.

Tip: Build in extra time for sampling and approvals. Rushing your denim order can lead to mistakes.

Shipping and Delays

Shipping adds another layer to your denim timeline. If you work with a local manufacturer, you get your denim in days, not weeks. Shipping from Asia takes longer. Ocean freight can add 3 to 6 weeks to your schedule. Air shipping moves faster but costs much more.

Delays can happen. Weather, customs, or port congestion can slow down your denim delivery. You might face extra fees or paperwork. Here are some ways to stay on track:

Track your denim shipment online.

Ask your manufacturer for regular updates.

Choose reliable shipping partners.

If you want to launch your denim brand on time, plan for possible delays. Good communication with your manufacturer helps you avoid surprises.

Ethics and Sustainability

Labor Practices

When you choose a denim manufacturer, you want to know how they treat their workers. Labor practices can shape your brand’s story and reputation. In the USA, denim factories must follow strict rules to keep workers safe and healthy. These rules cover everything from machine safety to chemical handling. You can see some of the main standards in the table below:

Labor Standard/Regulation | Description |

|---|---|

Environmental Regulations | U.S. denim manufacturers must adhere to strict guidelines for chemical usage, water treatment, and waste management to minimize environmental impact. |

OSHA Standards | The Occupational Safety and Health Administration enforces safety standards for machinery operation, chemical handling, and personal protective equipment to protect workers. |

Clean Water Act Compliance | Denim factories must invest in wastewater treatment systems to meet standards concerning toxic residues from dyeing and washing processes. |

Factories in Asia may follow different rules. Some countries have strong labor laws, but others do not enforce them as tightly. You might find denim made in places where workers face long hours or unsafe conditions. That’s why it helps to ask your manufacturer about their labor policies. Look for certifications or audits that show they care about worker safety.

If you want your denim brand to stand out, choose partners who value fair wages and safe workplaces.

Environmental Impact

Sustainability matters more than ever in the denim world. You want to know how your jeans affect the planet. American denim manufacturers must follow tough environmental rules. They treat water before releasing it and use safer chemicals. This helps protect rivers and communities near the factories.

Asian denim mills are making progress, too. Many now use less water and energy. Some even recycle water or use eco-friendly dyes. You can find denim made with organic cotton or recycled fibers. These steps help reduce pollution and waste.

Here are a few ways you can support sustainability in denim:

Pick manufacturers who use water-saving technology.

Ask about recycled materials in their denim.

Choose partners who share your values on sustainability.

When you care about ethics and sustainability, your customers notice. You help protect workers and the environment, and you build a denim brand people trust.

Best Jeans Manufacturers: Case Examples

USA Small Brand Success Story

You want your brand to stand out, so you look for the best jeans manufacturers in the USA. Imagine you launch a small label in Los Angeles. You choose an american jeans manufacturer that specializes in selvedge denim. You start with a low minimum order, just 30 pairs. This helps you test your designs without a big risk.

Your manufacturer uses premium american cotton and classic shuttle looms. You visit the factory and see the care that goes into every pair. The team helps you tweak your fit and finish. You get quick answers to your questions. Your first collection sells out fast. Customers love the story behind your jeans and the quality of the denim. You build a loyal following and soon expand your line.

The best jeans manufacturers in the USA know how to support small brands. They offer flexibility, fast turnaround, and a focus on craftsmanship. You get to tell your customers about american heritage and sustainable practices. As the premium denim market grows, you see more brands choosing local production to control costs and quality.

Aspect | Details |

|---|---|

Market Growth Rate | Projected CAGR of 8.3% for luxury denim jeans from 2025 to 2032. |

Key Drivers | High-end apparel demand, casual luxury trends, tech advancements. |

Sustainability Focus | Brands shift to responsible sourcing and eco-friendly practices. |

Asia Small Brand Success Story

You want to launch a unique collection, so you search for the best jeans manufacturers in Asia. You find a jeans manufacturer in China that lets you order just 100 pieces. This low MOQ means you don’t have to spend a lot up front. You work with their team to create custom fits and washes. The factory uses advanced techniques, so your denim stands out.

Here’s how small brands benefit when they choose the best jeans manufacturers in Asia:

You get lower minimum order quantities, which lowers your financial risk.

You access advanced manufacturing, so your jeans look and feel premium.

You can test new styles and washes without holding too much inventory.

You see your jeans manufacturer delivers on time and helps you with every step. Your customers notice the quality and unique details. You grow your brand quickly because you can try new ideas without a huge investment. The best jeans manufacturers in Asia keep up with the premium denim market by investing in new technology and sustainable practices. You find that both japanese and chinese mills now offer eco-friendly options and innovative finishes.

The premium denim market keeps changing. Both american and japanese manufacturers adapt by focusing on quality, sustainability, and flexibility. You have more choices than ever when you look for the best jeans manufacturers for your brand.

Choosing the right denim manufacturer depends on what matters most to you. If you want cost efficiency and flexible MOQs, Asian denim partners often deliver. For premium quality or ethical sourcing, American or Japanese denim makers stand out. Consider these factors:

Cost, lead times, and customization options

Sustainability practices and quality control

Certifications like ISO 9001 or Fair Trade

Ask yourself what denim means for your brand. Think about your long-term vision and how each manufacturer supports your goals. The best denim partner helps you grow with confidence.

FAQ

What is the typical minimum order quantity (MOQ) for small brands?

You can usually start with 50 to 100 pieces per style in the USA. Asian manufacturers often offer similar MOQs. Always ask your supplier about their minimums before you commit.

How do I make sure my denim quality meets my standards?

Request samples before placing a full order. Visit the factory if possible. Share clear specs and photos. Reliable manufacturers will send you swatches and prototypes so you can check fabric, stitching, and fit.

Are Asian denim manufacturers reliable for small brands?

Many Asian mills work with small brands and deliver consistent results. Look for verified suppliers with good reviews. Ask for references or case studies. Good communication helps you avoid surprises.

How do tariffs and shipping affect my total cost?

Tariffs can raise your costs when you import from Asia. Shipping fees and customs charges add up fast. Compare total landed costs with local production. Sometimes, paying more upfront saves you money later.