Imagine you want to launch a new product, but high MOQs hold you back. You need agility to respond quickly, test ideas, and avoid waste. Ai flexibility gives you that power. It lets you optimize production cycles, minimize downtime, and reduce costs. With ai flexibility, you gain agility in every step, from real-time data to automation. Small brands now compete with larger players by using ai flexibility for cost savings and agility. Review the table below to see how ai flexibility delivers real value:

Benefit | Percentage Reduction |

|---|---|

Maintenance Costs | |

Unplanned Downtime | 50% |

Operational Costs | Up to 30% |

Energy Costs | 20% or more |

Key Takeaways

AI flexibility allows small brands to compete with larger companies by reducing costs and increasing agility in production.

Implementing AI in small-batch production can lead to significant savings, including up to 40% in maintenance costs and 50% in unplanned downtime.

Using AI for real-time data analysis helps businesses quickly adapt to market changes and customer feedback, enhancing responsiveness.

Low minimum order quantities (MOQs) enable startups to test new products without financial strain, fostering innovation and reducing waste.

Adopting AI-driven solutions streamlines supplier sourcing, improves inventory management, and supports sustainable production practices.

AI Flexibility in Small-Batch Production

Cost Optimization with AI

You can achieve significant cost savings in small-batch production by using AI-powered systems. These systems refine design structures, which helps you minimize material use and reduce production costs. You also support sustainability when you optimize resources. AI automates complex design tasks, so your team spends less time on manual work and more time on innovation. This leads to faster prototyping and quicker market entry. AI analyzes large datasets to enable predictive maintenance. You extend equipment lifespans and reduce operational disruptions.

AI enhances resource utilization for small-batch production.

Automation speeds up prototyping and innovation.

Predictive maintenance reduces downtime and boosts efficiency.

Faster Market Response

You need to respond quickly to market changes in small-batch production. AI helps you analyze small datasets and gives you actionable insights faster than traditional methods. You can collect data within days and make decisions quickly. AI categorizes customer feedback into patterns in under 15 minutes. This speed lets you adapt your batch production to market trends and customer needs.

Tip: Use AI to monitor feedback and adjust your small-batch production strategy in real time.

Evidence Description | Impact on Lead Times in Small-Batch Production |

|---|---|

Smart, modular automation and cobots offer flexibility for small-batch production. | Enables faster changeovers and reduces downtime. |

Modular process design supports flexible, scalable setups for products. | Facilitates quicker changeovers and minimizes downtime. |

Implementing modular lines and quick-change tools simplifies processes. | Increases flexibility and adaptability, helping to eliminate bottlenecks. |

Precision filling technologies and single-use systems combat product loss. | Streamlines processes, contributing to improved efficiency and reduced lead times. |

Enhanced Product Customization

You can offer more product customization options in small-batch production with AI flexibility. The AI2SB project shows how digital twins and AI improve flexibility in production systems. You manage small-batch and even single-batch production efficiently. This approach lets you meet the demand for custom products while keeping costs low. AI increases flexibility and customization, so you deliver mass customization without losing efficiency. You can personalize products for your customers and scale your batch production as needed.

Note: Digital solutions give you the flexibility and customization needed for small-batch production success.

MOQ Challenges for Startups

Why High MOQs Limit Growth

You often face high moq requirements when you try to launch a new product. Manufacturers set minimum order quantity levels to cover set-up costs and achieve bulk production efficiencies. They also use bulk purchasing to manage inventory and materials. These practices help large companies, but they create barriers for you as a startup. Many suppliers demand thousands of units per SKU, which can stop you from testing new ideas or entering the market. You must choose between overproducing or abandoning your concept. This dilemma slows your growth and limits your ability to innovate.

Impact of MOQs | High MOQs | Low MOQs |

|---|---|---|

Financial Burden | Yes | No |

Flexibility in Production | Limited | High |

Risk of Unsold Stock | High | Low |

Ability to Test Market | No | Yes |

Innovation Stifling | Yes | No |

RYZEAL SOURCING shows that high moqs often lead to overproduction and financial strain. When you work with low minimum order quantities, you gain the freedom to experiment and bring new products to market.

Inventory and Cash Flow Risks

You risk tying up your cash flow when you commit to high moq orders. Large initial outlays reduce your financial flexibility. You may end up with excess inventory, which increases storage costs and the chance of waste or obsolescence.

Challenge | Impact |

|---|---|

Large initial outlays | Reduced cash flexibility |

Overstock risk | Possible wastage/obsolescence |

High storage needs | Increased operational expenses |

You might also face unsuitable packaging choices due to rigid moqs, which can trap you financially if demand shifts.

Excess inventory increases your costs and storage burdens.

Cash flow constraints make it harder to invest in new ideas.

The Need for Flexible Solutions

You need flexible solutions for overcoming challenges in small-batch production. You can select versatile fabrics to meet supplier moqs without large commitments. Start with simple, clean designs to minimize setup costs. Build long-term relationships with manufacturers who support small orders. Work with low moq clothing manufacturers to enable small-batch production. These strategies help you overcome challenges in small-batch production and reduce risk.

Tip: Flexible solutions like low minimum order quantities let you test products and adapt quickly to market changes.

AI Solutions for Dynamic MOQs

Automated Production Scheduling

You can use AI-powered production scheduling to manage small-batch manufacturing with low moq requirements. These systems help you adapt production volumes quickly, which is essential for flexible order sizes and low moq pod operations. AI-driven weaving solutions allow you to adjust staffing levels based on demand, so you avoid labor waste and keep costs low. You can respond to customer orders and prioritize production runs that matter most. Seasonal production planning becomes easier when you use historical data to predict demand. Rapid response rescheduling lets you shift priorities without slowing down your workflow.

Here is how automated scheduling features support small-batch and low moq print on demand:

Feature | Description |

|---|---|

Dynamic Production Volume Adaptation | Adjusts staffing levels based on production demands, ensuring efficient workforce allocation. |

Just-in-Time Labor Allocation | Aligns worker scheduling with production needs, minimizing labor waste during low-demand periods. |

Order-Driven Scheduling | Responds to customer orders and backlogs, prioritizing critical production runs with adequate staffing. |

Seasonal Production Planning | Uses predictive scheduling to accommodate seasonal variations based on historical demand patterns. |

Rapid Response Rescheduling | Allows quick adjustments to schedules in response to unexpected orders or shifts in production priorities. |

You gain improved resource utilization and reduce costs when you use automated scheduling. Real-time monitoring allows you to make immediate adjustments, which increases operational efficiency and reduces downtime. You can reduce lead times and respond faster to market demands. This approach supports sustainability and ethical production because you minimize waste and optimize resources.

Mechanism | Benefit |

|---|---|

Improved Resource Utilization | Leads to reduced costs and increased efficiency in production processes. |

Demand Forecasting | Enhances inventory management, reducing stockouts and overproduction. |

Real-time Monitoring | Allows for immediate adjustments, increasing operational efficiency and reducing downtime. |

Reduced Lead Time | Provides a competitive advantage by enabling faster response to market demands. |

Effective production planning and scheduling can lead to reduced lead times and lower inventory costs.

AI can forecast demand more accurately, improving inventory management.

Real-time monitoring allows for immediate adjustments to schedules, enhancing efficiency.

Smart factories use AI to enable flexible small-batch production and low moq pod. Machines, sensors, and humans connect through digital networks, which allows seamless data flow. Predictive maintenance helps you avoid breakdowns and keep production running smoothly. You can reconfigure smart factories to handle different products and batch sizes, which supports low moq print on demand and sustainability. AI instantly flags flaws and maintains precise control over product quality. You minimize setup and machine idle time, reduce material wastage, and make dynamic adjustments without restarting production.

Aspect | Description |

|---|---|

Interconnectivity | Machines, sensors, devices, and humans are linked through a digital network, allowing seamless data flow. |

Predictive Maintenance | Equipment can self-monitor for maintenance needs, reducing downtime and enhancing production efficiency. |

Customization and Flexibility | Smart factories can quickly reconfigure to handle different products and batch sizes, meeting consumer demands. |

Sustainability | Optimizes resource use and reduces waste, contributing to a more sustainable production process. |

Minimizes setup and machine idle time.

Reduces material wastage through better pattern simulation.

Allows dynamic adjustments without restarting production.

Predictive Analytics for Demand

You can use predictive analytics to improve demand forecasting for small-batch production and low moq pod. This technology helps you reduce stockouts and overstock, which is crucial for low moq print on demand and ethical business practices. You get accurate predictions that allow you to optimize your stock levels and plan procurement better. You achieve higher cost efficiency because you avoid unnecessary expenses related to inventory mismanagement.

Predictive analytics helps reduce stockouts and overstock, which is crucial for small-batch production.

It enhances inventory management by providing accurate predictions, allowing businesses to optimize their stock levels.

Improved supplier and procurement planning is achieved through better forecasting of future trends and demands.

Higher cost efficiency is realized as businesses can avoid unnecessary expenses related to inventory mismanagement.

Print-on-demand models benefit from AI-driven production management. AI scheduling minimizes downtime and tool swaps, which raises output without extra capital. Computer vision inspects surfaces and assemblies in real time, so you reduce defect escape. Human and AI collaboration boosts productivity by about 30 percent. Predictive analytics reduces rework by up to 50 percent and decreases energy use by 20 percent, which supports sustainability and ethical production. Real-time dashboards track key performance indicators, so you make data-driven decisions.

Benefit | Description |

|---|---|

AI scheduling minimizes downtime and tool swaps, raising output without additional capital expenditure. | |

Quality Control | Computer vision inspects surfaces and assemblies in real-time, significantly reducing defect escape. |

Enhanced Efficiency | Human + AI collaboration can boost productivity by approximately 30%, dividing tasks effectively. |

Predictive Analytics | Reduces rework by up to 50% and decreases energy expenditure by 20%, improving overall operational performance. |

Real-time Monitoring | Dashboards track key performance indicators, allowing teams to make data-driven decisions. |

Supplier Search and Sourcing

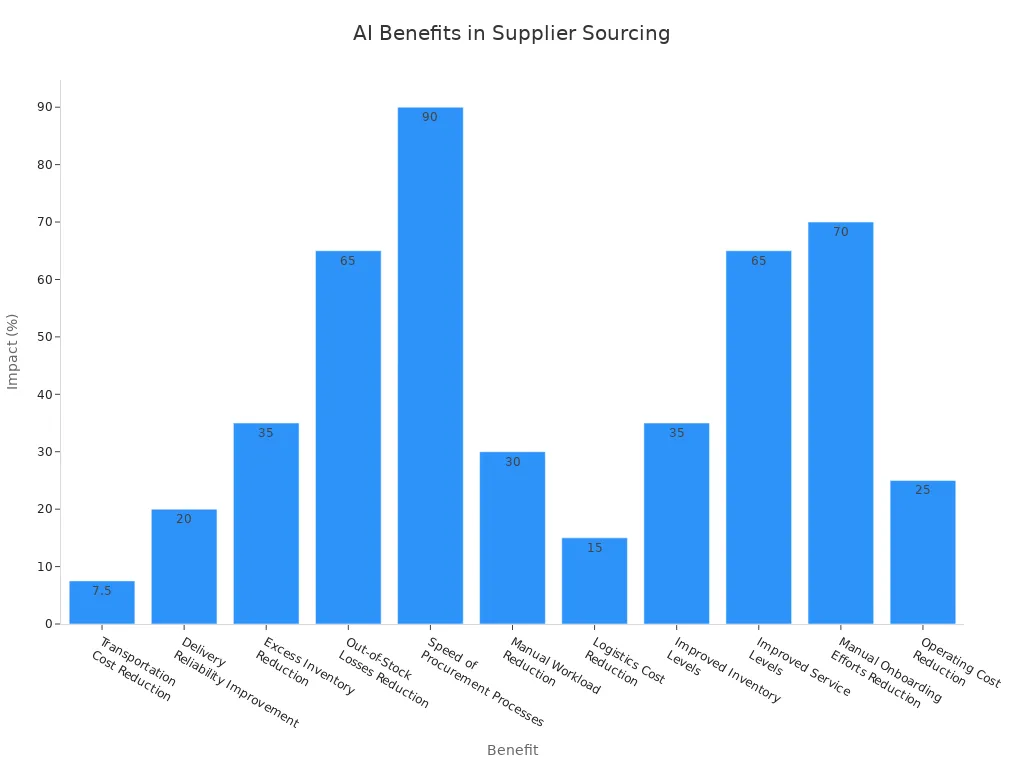

You can use AI to streamline supplier search and sourcing for small-batch production and low moq pod. AI helps you find suppliers who support low moq print on demand and ethical practices. You reduce transportation costs by 5 to 10 percent and improve delivery reliability by up to 20 percent. You cut excess inventory by 35 percent and reduce out-of-stock losses by 65 percent. Procurement processes become 90 percent faster, and you lower manual workload by 30 percent. Logistics costs drop by 15 percent, and you improve inventory levels by 35 percent. Service levels improve by 65 percent, and you reduce manual onboarding efforts by 70 percent. Operating costs can drop by up to 25 percent, and risk forecasting accuracy improves, with errors reduced from 25 to 40 percent.

Benefit | Measurable Impact |

|---|---|

Transportation Cost Reduction | 5-10% |

Delivery Reliability Improvement | Up to 20% |

Excess Inventory Reduction | 35% |

Out-of-Stock Losses Reduction | 65% |

Speed of Procurement Processes | 90% faster |

Manual Workload Reduction | 30% |

Logistics Cost Reduction | 15% lower |

Improved Inventory Levels | 35% better |

Improved Service Levels | 65% improved |

Manual Onboarding Efforts Reduction | 70% |

Operating Cost Reduction | Up to 25% |

Risk Forecasting Accuracy | Errors reduced from 25-40% to lower |

You can use low moq solutions to test new products and adapt quickly to market changes. AI helps you find suppliers who support low moq print on demand and sustainable fashion. You build relationships with ethical suppliers who value sustainability and ethical production. On-demand manufacturing becomes possible when you use AI to manage sourcing and procurement. You support sustainability and ethical production by reducing waste and optimizing resources.

You can use low moq pod to launch new products with minimal risk. AI-driven weaving solutions help you create small-batch products that meet ethical standards. You support sustainability and ethical production by choosing suppliers who value these principles. You can use low moq print on demand to offer customized products and respond quickly to customer needs. AI helps you manage inventory, reduce costs, and improve efficiency in small-batch production.

Real-World Impact and Action Steps

Startup Success Stories

You can see how AI flexibility transforms small-batch production by looking at real companies.

Nike uses AI in its Nike By You platform. You can personalize shoes, and Nike optimizes production schedules to handle low moq orders.

L’Oréal employs AI in its Perso device. You get personalized cosmetics based on your data, and the company manages small-batch production efficiently.

Proto Labs offers rapid low-volume production. AI helps you optimize part design and manufacturability, making it easier to meet moq requirements.

Xometry provides an AI-driven platform for on-demand manufacturing. You can produce custom parts efficiently, even when launching niche products.

These brands show you that AI flexibility supports small-batch production, customized merchandise, and low moq strategies.

Steps to Implement AI Flexibility

You can follow a clear path to bring AI flexibility into your production process.

Step | Description |

|---|---|

1. AI Implementation Strategy | Identify potential AI use cases and prioritize based on ease and impact. Focus on quick wins to build momentum. |

2. Build vs Partner Strategy | Decide whether to develop AI in-house or partner with consultants based on skills and speed requirements. |

3. Validation Strategy | Create a Minimum Viable AI (MVAI) and test it in controlled environments before full deployment. |

4. Scaling and Operational Strategy | Integrate AI into daily workflows and ensure continuous training and deployment. |

5. Continuous Improvement and Governance Strategy | Regularly audit AI performance and update models to maintain compliance and effectiveness. |

You can use these steps to manage moq challenges, improve efficiency, and support launching niche products.

Avoiding Common Pitfalls

You may face obstacles when you adopt AI-driven small-batch production.

Employee resistance and limited AI knowledge can slow progress. You should provide tailored training and engage staff early to build confidence.

Staff may lack clarity on AI tools. A change management plan helps you avoid delays.

You might underestimate the need for high-quality data. Conduct a data audit before you start. If your data is inadequate, consider synthetic data generation or partnerships.

Lack of talent can hinder AI adoption. If hiring experts is not possible, partner with AI vendors or universities.

Neglecting ethical considerations can damage your reputation. Responsible AI practices build customer trust.

AI should connect to your overall business strategy. Make sure your AI initiatives support customer needs and operational efficiency.

You can avoid these pitfalls and use AI flexibility to manage moq, reduce risk, and deliver customized merchandise.

You can unlock economical small-batch production by using AI flexibility and dynamic moq strategies. These tools help you lower costs, boost agility, and reduce risk. The table below shows how AI-driven production outperforms traditional models:

Aspect | AI-Driven Production | Traditional Production |

|---|---|---|

Agility | Adapts to real-time data | Slower response |

Cost Savings | Lower investment, fewer errors | Higher costs, more risk |

Customization | Personalized products | Limited options |

Startups like yours can test new ideas with low moq, use real-time analytics, and speed up product development. Take steps to explore AI-driven solutions and keep your team ready for change. The future of small-batch manufacturing will bring even more design innovation and smarter moq management.

FAQ

What is the main benefit of using AI for small-batch production?

You gain flexibility and cost savings. AI helps you adjust production quickly, reduce waste, and respond to market changes. This makes small-batch production more affordable and efficient.

How does AI help you lower MOQs?

AI analyzes demand and optimizes scheduling. You can produce only what you need. This lets you order smaller quantities and test new products without large investments.

Can AI improve product customization for your brand?

Yes! AI enables you to personalize products based on customer data. You can offer unique options and adapt designs quickly. This helps you stand out in the market.

Is it hard to start using AI in your production process?

You can start small. Many tools offer easy integration. Begin with one area, like scheduling or demand forecasting. > Tip: Choose a solution that matches your current needs and scale up as you grow.