Your competitors are already harnessing ai to dominate the market. In 2025, 77% of manufacturers use ai solutions, up from 70% last year. You want growth, efficiency, and less risk. An ai bridge can transform your operations by connecting you to ai factories and advanced automation. See how ai boosts productivity and delivers both instant and lasting value:

Description | |

|---|---|

Predictive Maintenance | ai minimizes equipment downtime by forecasting failures, leading to reduced operational disruptions. |

Quality Control and Defect Detection | ai systems detect defects with higher accuracy than human inspectors, improving product reliability. |

Process Optimization | Real-time optimization of processes increases yield and reduces energy consumption. |

Supply Chain and Inventory Management | ai enhances supply chain visibility and dynamically adjusts inventory levels to prevent shortages. |

Human-Robot Collaboration | ai-powered cobots work alongside humans, boosting productivity and safety in operations. |

Key Takeaways

Embrace AI to boost productivity and efficiency in manufacturing. AI solutions can lead to significant operational improvements.

Implement predictive maintenance to reduce equipment downtime. This approach can save costs and extend the life of your machines.

Enhance quality control with AI-driven inspections. AI can detect defects more accurately than humans, improving product reliability.

Utilize AI factories for rapid prototyping and scaling. This allows you to test new ideas quickly and adapt to market changes.

Foster collaboration between humans and AI. Building hybrid teams enhances problem-solving and drives innovation in your operations.

The Power of an AI Bridge

Fast-Tracking Innovation

You want to move faster than your competitors. An ai bridge gives you the speed you need. By connecting your operations to ai factories, you unlock rapid prototyping, instant feedback, and smarter design cycles. You can test new ideas in digital twins and see results in seconds. This approach replaces slow, manual processes with ai automation and intelligent automation.

Manufacturers who use an ai bridge report dramatic improvements in productivity and efficiency. Take a look at the most significant benefits:

Benefit | Description |

|---|---|

Enhanced Productivity | AI solutions lead to significant productivity gains, improving overall operational efficiency. |

Reduced Operational Costs | Predictive maintenance prevents costly equipment failures, saving money on repairs. |

Improved Product Quality | AI tools detect defects more reliably than manual inspections, reducing waste and rework. |

Faster Time to Market | Generative AI speeds up design and testing, allowing quicker product launches. |

Smarter Supply Chains | AI enhances demand forecasting and inventory management, reducing shortages and excess stock. |

Stronger Sustainability | AI optimizes resource use, helping companies meet environmental goals while cutting costs. |

You can see how ai factories and ai automation drive results. For example, Eaton used ai-based generative design with aPriori and achieved an 87% reduction in development time. Their design quality improved, and they moved products to manufacturing much faster.

You do not have to wait months for simulation results. AI-powered Reduced Order Models let you simulate parts in seconds. AI-driven simulation acceleration cuts the number of full simulations by over 20%. You can test changes in a digital environment and launch products ahead of schedule.

When you use ai infrastructure and connect to advanced data centers, you gain access to powerful ai applications. These tools help you analyze data, optimize processes, and make smarter decisions. You can scale your automation technologies and adapt quickly to market changes.

Future-Proofing Manufacturing

You want your business to thrive in the future. An ai bridge prepares you for new challenges and disruptions. By partnering with ai factories, you build resilience and agility into your operations. Adaptive ai learns from new data and responds to changing conditions automatically. You do not need to retrain models or troubleshoot systems constantly.

Adaptive ai reduces decision-making delays.

It responds to new business conditions without manual intervention.

It frees up your engineering team for higher-value work.

It strengthens resilience in customer-facing and operational workflows.

Deloitte’s research shows that predictive maintenance powered by ai can cut plant downtime by 5-20%. This addresses a major industry challenge that costs manufacturers $50 billion each year in unplanned outages. You save money and keep your production lines running smoothly.

David R. Brousell, Co-founder of the NAM’s Manufacturing Leadership Council, urges manufacturers to accelerate their understanding and use of ai technologies. Your competitiveness depends on your expertise and application of ai. If you invest in ai automation and ai factories now, you stay ahead of the curve.

AIoT is changing the game. You can expect major cost savings, smarter innovation, and more efficient operations. Most manufacturers believe ai will strengthen productivity and competitiveness. AI and generative ai are revolutionizing predictive maintenance and supply chain optimization. You gain operational capabilities that were impossible before.

When you build human-AI partnerships, you amplify your team’s abilities. AI enhances economic competitiveness and prepares your workforce for future roles. You create a culture of innovation and adaptability.

You do not just solve today’s problems. You prepare for tomorrow’s opportunities. An ai bridge connects you to the future of manufacturing, powered by ai factories, ai automation, and advanced ai applications.

Why AI Factories Drive Results

Agility and Scale in Operations

You want your manufacturing operations to move faster and grow without limits. AI factories give you the agility and scale you need to stay ahead. When you connect your business to ai factories, you unlock rapid piloting and instant scaling of validated use cases. You do not waste time on slow, manual processes. Instead, you use ai automation and intelligent automation to deploy new solutions quickly.

AI factories use modular systems. You can reuse modules and deploy them across different lines, which speeds up your rollout. Automated lifecycle management lets you train and deploy ai models with consistency. You do not have to worry about errors or delays. Integration of cloud and edge computing means you get real-time inference and fast response times. Your ai infrastructure works with both data centers and shop floor devices, so you scale up without bottlenecks.

Here is how ai factories help you achieve agility and scale:

Evidence Description |

|---|

AI factories automate and optimize the lifecycle of ai systems, enhancing agility. |

They enable efficient handling of data, which supports scalability in operations. |

Standardized processes reduce the time from data to deployment, increasing agility. |

Continuous feedback loops allow for ongoing model refinement, improving outcomes. |

They facilitate rapid deployment of ai models, contributing to operational scalability. |

You see the benefits in every part of your operation. AI automation streamlines repetitive tasks. Your team focuses on strategic work. Quality control becomes more precise. Predictive maintenance keeps your machines running. Cost efficiency improves as you reduce waste and energy use. Enhanced decision making comes from real-time data and insights. Process optimization boosts your productivity and keeps your business competitive.

Startups and partnerships with ai experts play a key role. They bring agility and fresh ideas. You can pilot ai solutions with lower risk. Only validated use cases expand, so you maximize ROI. You solve legacy challenges with new ai applications. You get faster prototyping and deployment. Your business becomes more resilient and future-ready.

Tip: Use ai factories to test new automation technologies in small pilots. Scale up only the solutions that deliver real results. This approach reduces risk and accelerates your return on investment.

Human-AI Collaboration

You want your workforce to thrive alongside ai. AI factories make human-ai collaboration possible and powerful. Human-in-the-loop strategies combine your team’s judgment, creativity, and empathy with ai automation. You get trusted, high-performing ai on the shop floor.

Domain-specialist hybrid pods integrate expert human teams with specialized ai. Security-focused pods combine ai vulnerability detection with human expertise. Performance optimization pods use ai profiling and human decision-making. Frontend development pods blend ai component generation with human UX validation. You build a culture where humans and ai work together to solve problems and innovate.

You can follow a proven path to successful human-ai collaboration:

Maturity Assessment – Check your team’s readiness for ai technologies.

Modular Pilot Programs – Start small and show value quickly.

Toolchain Integration – Make sure ai tools fit with your existing systems.

Continuous model retraining keeps your ai applications accurate. Ethical guardrails prevent bias. KPI dashboards track deployment frequency and quality metrics. You use feedback loops to refine your ai models and improve outcomes.

AI factories empower your team. You use ai automation to handle routine tasks. Your engineers focus on higher-value work. You create new business models and unlock new opportunities. AI infrastructure supports your growth. Automation technologies drive efficiency and innovation.

Note: Human-ai partnerships amplify your workforce’s abilities. You prepare your team for future roles and build a resilient, adaptable organization.

AI factories transform your manufacturing operations. You achieve agility, scale, and collaboration. You reduce risk and accelerate ROI with startups and expert partners. You use ai automation, intelligent automation, and advanced ai applications to lead your industry.

Solving Manufacturing Challenges with AI

You face tough challenges in manufacturing every day. AI, ai factories, and ai automation give you the tools to overcome them. When you connect your operations to ai infrastructure and data centers, you unlock new levels of productivity and efficiency. Let’s see how ai applications and intelligent automation solve your biggest problems.

Predictive Maintenance

AI-powered predictive maintenance changes the game for your equipment. You can monitor machines in real time and predict failures before they happen. This approach increases productivity by 25%, reduces breakdowns by 70%, and lowers maintenance costs by 25%. Many manufacturers have seen a 40% drop in unplanned downtime after using smart sensor monitoring. General Electric cut unplanned downtime by 30%. Early fault detection prevents wear and tear, so your machines last 20-30% longer. You save money and keep your lines running.

AI predictive maintenance extends equipment life by about 40%.

Maintenance costs drop by 18-25%.

You reduce downtime by up to 50%.

Tip: Use ai automation to schedule repairs only when needed. This keeps your machines healthy and your costs low.

Quality Control

AI factories and ai automation make quality control faster and more accurate. AI-based computer vision systems inspect products and spot defects that humans might miss. You minimize defects and improve product standards, which leads to big cost savings. BMW saw a 30% reduction in defect rates and a 15% boost in customer satisfaction. Samsung Electronics cut customer return rates by 31% with early defect identification.

Company | Improvement in Defect Detection Rates | Additional Impact |

|---|---|---|

BMW | 30% reduction in defect rates | 15% increase in customer satisfaction |

Samsung Electronics | 31% reduction in customer return rates | Early defect identification in microchips |

AI-driven analytics can improve defect detection rates by up to 50%. Some factories have cut defect rates by as much as 90%. Real-time inspection means fewer recalls and less waste. Your brand reputation grows stronger.

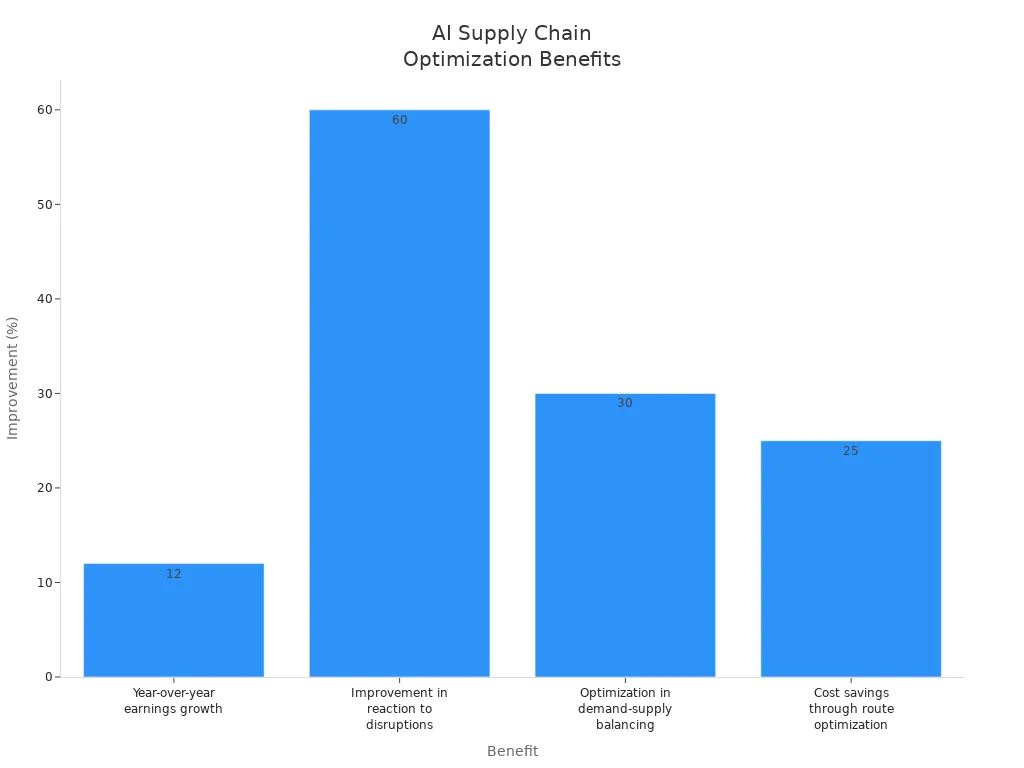

Supply Chain Optimization

AI and ai factories transform your supply chain. You get better forecasting, lower logistics costs, and faster response to disruptions. AI automation and intelligent automation help you balance demand and supply, cut excess stock, and reduce inventory holding costs by up to 50%. You improve service levels by 65% and increase forecast accuracy by 75%.

Benefit | Improvement Percentage |

|---|---|

Lower logistics costs | 15% |

Better inventory management | 35% |

Improvement in service levels | 65% |

Reduction in transport costs | Up to 30% |

Increase in forecast accuracy | 75% |

Reduction in inventory levels | 20% to 30% |

Cut in excess stock | Up to 25% |

Waste reduction for perishables | 20% |

AI technologies make your supply chain more resilient. You can respond quickly to market changes and disruptions. Haier Group used ai to let business units make fast decisions, boosting flexibility and risk resistance. AI applications improve transparency and trust among partners. You gain a supply chain that adapts and thrives in any environment.

When you use ai automation and ai factories, you solve your toughest manufacturing challenges. You build a future-ready business with stronger productivity and efficiency.

Building Successful AI Partnerships

Setting Clear Goals

You need clear goals to unlock the full potential of ai in your manufacturing journey. When you set precise objectives, you align every ai initiative with your business strategy. Start by linking ai goals to outcomes like cost reduction or revenue growth. Use SMART KPIs—specific, measurable, achievable, relevant, and time-bound—to track progress. Involve cross-functional teams so every department contributes to defining success. Regularly review and adjust your KPIs as your business evolves. Leverage ai analytics tools to refine your metrics and keep your ai automation efforts on target.

Best Practices for Goal Setting:

Connect ai goals to strategic outcomes.

Make KPIs SMART for actionable tracking.

Choose metrics that show both technical and business value.

Engage stakeholders from every department.

Align everyone on what success means.

Review and update KPIs often.

Use ai tools for efficient KPI management.

Tip: Clear goals and defined metrics help you measure performance, identify inefficiencies, and drive data-driven improvements with ai factory solutions.

Fostering Collaboration

You build strong ai partnerships by fostering a culture of collaboration. Bring together your manufacturing experts and ai specialists to create hybrid teams. Encourage open communication and shared problem-solving. When you involve stakeholders from engineering, operations, and IT, you ensure that ai automation fits seamlessly into your workflows. Collaboration helps you overcome challenges like integration complexity and lack of ai expertise. You create an environment where everyone works toward common objectives and embraces intelligent automation.

Collaboration Strategy | Benefit |

|---|---|

Cross-functional teams | Faster problem-solving |

Open communication | Fewer integration barriers |

Shared KPIs | Unified direction |

Continuous feedback | Improved ai automation |

Note: A partnership culture with clear metrics keeps your ai factories agile and your automation initiatives focused on real business value.

Seamless Integration

You achieve seamless integration by planning strategically and building strong foundations. Start with a full data inventory and integration plan. Use modern frameworks to connect your ai infrastructure with legacy systems. Automate repetitive tasks with ai automation, such as intelligent routing and chatbots. Invest in workforce development so your team understands both manufacturing and ai technologies. Implement pilot projects to test ai factory solutions before scaling up. Address technical barriers, data quality issues, and security challenges early to avoid disruptions.

Action Steps for Integration:

Conduct a data inventory and assess quality.

Collaborate with cross-functional teams for integration planning.

Use secure, modern technical architecture.

Automate workflows with ai automation.

Deploy ai-powered decision-making tools.

Train your workforce in ai technologies.

Start with pilot projects and scale successful solutions.

Seamless integration of ai automation and ai factories boosts productivity and future-proofs your operations.

You unlock new business models and future-proof your operations when you build an ai bridge and partner with ai factories.

AI enhances adaptability and preserves your team’s knowledge.

Collaboration between humans and ai strengthens resilience.

Strategic leadership and unified vision drive measurable gains in productivity and innovation.

Proactive skills development prepares your workforce for future roles.

Act now. Most manufacturers already use ai, but only those who align technology and talent strategies will lead in efficiency and automation. Invest in ai bridge solutions to secure long-term success.

FAQ

What is an AI bridge in manufacturing?

An AI bridge connects your existing systems to advanced ai solutions. You gain access to automation, analytics, and smarter workflows. This bridge helps you modernize without replacing your entire infrastructure.

How quickly can I see results from AI factories?

You can see results in weeks, not months. AI factories let you pilot solutions fast. You test, validate, and scale only what works. This approach reduces risk and accelerates your return on investment.

Do I need to hire new staff to use AI?

You do not need to hire a whole new team. AI factories support your current workforce. You can upskill your employees and let ai handle repetitive tasks. Your team focuses on higher-value work.

Is AI secure for my manufacturing data?

You control your data. AI factories use strong security protocols. You can set permissions and monitor access. This keeps your sensitive information safe while you benefit from ai-driven insights.

Can AI help my business stay competitive?

Yes. AI gives you faster innovation, better quality, and lower costs. You can adapt to market changes and lead your industry. Investing in ai now secures your future growth.