You need to know the key denim quality checks to maintain high standards in manufacturing. Quick and effective quality control helps you catch issues before they reach your customers. Take a look at common checks used by most denim manufacturers:

Quality Check | Description |

|---|---|

Inspect Fabric Weight and Thickness | Ensure uniformity for better fit and comfort. |

Test Stretch Recovery Performance | Confirm elasticity and shape retention. |

Check Colorfastness | Prevent fading with wash tests. |

Detect Defects Early | Spot holes or stains using visual and automated methods. |

Evaluate Tensile Strength | Test durability against pulling forces. |

When you use a checklist and the Denim Fabric Defect Detection Guide, you build trust and improve product consistency.

Key Takeaways

Conduct thorough fabric evaluations before production to catch defects early. This step saves time and prevents costly mistakes.

Implement a quality control checklist at every stage of manufacturing. This habit ensures consistent quality and builds customer trust.

Use automated inspection systems to detect flaws quickly. These systems can identify issues that human eyes might miss, improving efficiency.

Train your staff regularly on quality control methods. Well-trained employees can spot defects early and maintain high standards.

Choose reliable suppliers with strong quality control certifications. This practice helps ensure the quality of raw materials and reduces production issues.

Why Denim Fabric Quality Control Matters

Product Consistency

You want every pair of jeans to look and feel the same. Denim fabric quality control helps you achieve this goal. When you check fabric weight, thickness, and stretch recovery, you make sure each batch meets your standards. Quality must be built in at every stage of denim production. You inspect fabric, monitor cutting, and check sewing lines. These steps help you avoid surprises and keep your products consistent. If you skip quality checkpoints, you risk uneven color, weak seams, or poor fit. Consistent quality means your customers trust your brand and return for more high-quality jeans.

Brand Reputation

Your brand reputation depends on the quality of your products. Denim fabric quality control protects your image in the market. When you deliver jeans that last and look great, you build customer loyalty. You also stand out from competitors who may overlook quality. Rigorous inspections, including final checks before shipping, show your commitment to excellence. If you ignore quality control, you may face complaints, returns, or lost sales. Customers expect reliable products, and denim fabric quality control helps you meet those expectations.

Tip: Use a checklist for every stage of manufacturing. This habit helps you catch issues early and maintain your brand’s reputation.

Cost and Waste Reduction

You save money and reduce waste when you use denim fabric quality control. Early inspections help you spot defects before they become expensive problems. You can optimize cutting patterns and use precise tools to lower fabric waste. Understanding fabric requirements allows you to calculate costs accurately. Strict quality control measures ensure uniform quality across batches, which reduces defects and rework. These steps improve production efficiency and help you avoid unnecessary expenses.

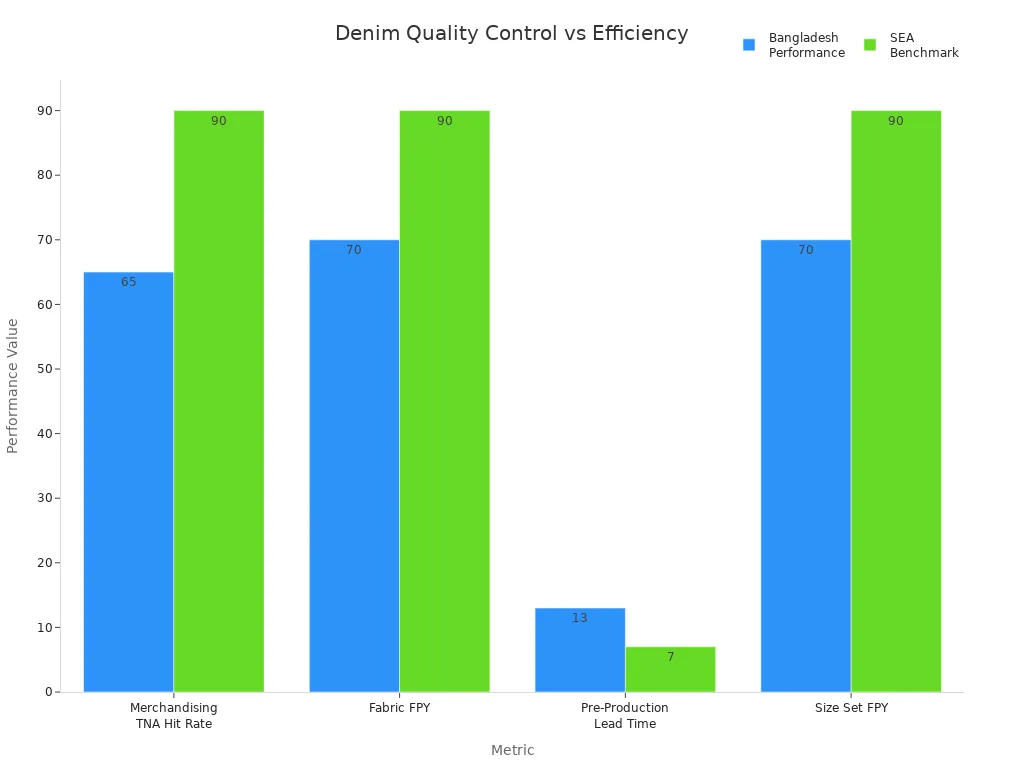

Metric | Bangladesh Performance | SEA Benchmark | Performance Gap |

|---|---|---|---|

Merchandising TNA Hit Rate | 65% | 90% | 25% |

Fabric FPY | 70% | 90% | 20% |

Pre-Production Lead Time | 13 days | 7 days | 6 days |

Size Set FPY | 70% | 90% | 20% |

You can see that strong denim fabric quality control leads to better results in manufacturing. When you focus on quality, you improve efficiency and reduce waste.

Denim Fabric Quality Control Checklist

A strong quality control checklist helps you catch problems early and deliver consistent denim products. You need to follow each step to make sure your denim meets industry standards. Use this checklist to guide your denim fabric quality control process from start to finish.

Fabric Evaluation and Pre-Cutting Checks

You start with fabric evaluation before you cut or sew anything. This step forms the foundation of denim fabric quality control. You want to check for weaving defects, shade variations, and other issues that can affect the final product. Use a checklist to track each stage:

Step | Description |

|---|---|

1 | |

2 | Inspection after weaving |

3 | Inspection after dye/finishing |

4 | Post-wash evaluation |

5 | Inspection before cutting/sewing |

6 | Final product/pre-shipment check |

You should also:

Vet your suppliers for past performance and quality control capacity.

Place sample orders to test key performance metrics.

Use in-process quality control with periodic sampling.

Keep feedback logs and track defect rates for improvement.

Denim is made from long-staple cotton yarns, dyed in indigo vats, and woven into twill fabric. You need to check for defects, verify GSM (grams per square meter), and test for shrinkage and colorfastness. Always inspect cut panels to confirm they match the pattern for shape and size.

Quality control begins before the first stitch is ever sewn. The pre-production phase is your opportunity to catch potential issues with raw materials, preventing them from derailing the entire manufacturing process.

Shrinkage and Dimensional Stability

Shrinkage can ruin the fit of your jeans. You must test for shrinkage and dimensional stability as part of your denim fabric quality control checklist. Use standard methods like AATCC 135 and ISO 5077 to measure shrinkage in both warp and weft directions.

Collection Type | Wash Fastness | Dry Rub | Wet Rub | Shrinkage |

|---|---|---|---|---|

Core Denim | ≥4 | ≥3 | ≥2 | ≤3% |

Premium Denim | ≥4.5 | ≥4 | ≥3 | ≤2% |

Performance Denim | ≥4 | ≥4 | ≥4 | ≤2% |

Raw denim can shrink 5–7% after washing. Sanforized denim usually shrinks 1–3%. Enzyme pre-washed denim may shrink 2–4%. One-wash resin finishes keep shrinkage below 2%. You need to record these values in your checklist and reject any batch that does not meet your standards.

Color Consistency and Washfastness

Color consistency is critical for denim fabric quality control. You want every pair of jeans to look the same, even after denim washing. Use the following test methods to check colorfastness and washfastness:

Test Method | Standard Reference |

|---|---|

ISO 105-C06:2010 | |

Colorfastness to Light | ISO 105-B01:2014, ISO 105-B02:2014 |

Colorfastness to Rubbing | ISO 105-X12:2016 |

Colorfastness to Perspiration | ISO 105-E04:2013, AATCC 15 |

You should test for color changes after denim washing and exposure to light or sweat. Add these tests to your checklist to ensure your denim meets customer expectations.

Stitching and Seam Quality

Denim stitching holds your jeans together. You need to check every seam for strength and appearance. Your checklist should include:

Measure the garment against specifications for correct dimensions.

Check stitch length and tension for consistency.

Assess seam allowance and cleanliness to avoid bunching or poor fit.

Confirm the use of the right needle type to prevent fabric damage.

Inspect all denim stitching for skipped stitches, loose threads, or broken seams.

You want to test denim stitching at multiple points in production. This step ensures your jeans stay strong and look professional.

Garment Inspection and Packaging

The final steps in your quality control checklist focus on garment inspection and packaging. You need to check fit, accessories, and packaging to protect your product.

Inspection Type | Description |

|---|---|

Check garment fit on a mannequin against reference pictures. | |

Accessories Testing | Perform pull, fatigue, and stretch tests on zippers, buttons, and elastics. |

Packaging Inspection | Ensure packaging protects products and complies with regulations. |

Follow these steps:

Inspect fabrics, trims, and accessories before production.

Check denim stitching, measurements, and labeling during production.

Review finished garments for defects and proper packaging before shipment.

A complete quality control checklist helps you deliver denim products that meet high standards. You build trust with your customers and reduce costly returns.

Denim Fabric Defect Detection Guide

A strong denim fabric defect detection guide helps you keep your products free from flaws. You need to follow clear steps to spot problems before they reach your customers. This guide gives you practical ways to detect defects early and improve your quality control process.

Visual Inspection Steps

You can start with a hands-on approach. Visual inspection remains a key part of any denim fabric defect detection guide. Here are steps you should follow:

Lay out the denim fabric on a flat, clean surface.

Use bright, even lighting to see the fabric clearly.

Check for weaving faults, stains, holes, or color variations.

Inspect both sides of the fabric for hidden issues.

Mark any defects with stickers or chalk for easy identification.

Tip: Rotate your inspection team to keep eyes fresh and reduce missed defects.

You should record all findings in your denim fabric defect detection guide. This record helps you track patterns and improve future batches.

Automated Monitoring Systems

You can boost your quality control with technology. Many denim manufacturers now use automated inspection systems as part of their denim fabric defect detection guide. These systems use cameras and sensors to scan fabric at high speed. They spot small flaws that human eyes might miss.

Automated systems can check for:

Broken yarns

Color shading

Oil stains

Holes or slubs

You can set up alerts so you detect defects early and stop production if needed. Automated inspection systems help you save time and reduce waste. Add these tools to your denim fabric defect detection guide for the best results.

Strong Denim Fabric Quality Control Tips

Process Control and Real-Time Monitoring

You can improve denim fabric quality control by using process control and real-time monitoring. These steps help you spot problems as soon as they happen. You should set up checkpoints at every stage of production. Use sensors and cameras to track fabric defects and color changes. This approach lets you fix issues before they affect the whole batch. You can also use software to collect data and create reports. These reports show you where to focus your efforts. If you want strong denim fabric quality control, you need to act fast and use technology.

Tip: Review your process data every day. Quick action keeps your quality high and reduces waste.

Staff Training and SOPs

Your team plays a big role in denim fabric quality control. You need to train your staff on the latest methods and tools. Standard operating procedures (SOPs) give everyone clear steps to follow. You should update your SOPs often to match new industry standards. Hold regular training sessions and use hands-on practice. When your team knows what to do, you catch more mistakes early.

Use these tips for better results:

Teach staff how to spot common denim defects.

Show them how to use inspection tools.

Encourage questions and feedback.

Supplier Certifications

You should only work with suppliers who meet strict denim fabric quality control standards. Ask for certifications like ISO 9001 or OEKO-TEX. These show that your suppliers follow best practices. You can also visit their factories and check their processes. Reliable suppliers help you avoid problems with raw materials.

Tip: Keep a list of approved suppliers. Review their performance every year to make sure they still meet your standards.

You can use these tips to build a strong denim fabric quality control system. When you follow these steps, you protect your brand and deliver better products.

Common Issues and Quick Solutions

Denim manufacturing faces several recurring problems. You can solve these issues quickly if you know what to look for and how to act. Here are the most common challenges and practical solutions for each.

Inconsistent Fabric Batches

You may notice that some denim batches look or feel different. This problem often starts with shade variation or weaving defects. Use this quick approach to fix it:

Check the shade under controlled lighting to confirm the difference.

Sort fabric lots by shade—light, medium, or dark—to prevent mismatched garments.

Find the root cause, such as temperature changes during dyeing.

Calibrate dyeing equipment and run early checks for shade drift.

Communicate openly with buyers to maintain trust.

Tip: Keep a record of each batch’s shade and GSM to spot trends and prevent future inconsistencies.

Color Variation

Color variation can make jeans look uneven. You can reduce this issue by using advanced dyeing methods and careful chemical control.

Apply indigo with strategic chemical modifications for even color.

Use sulfur-bottoming and rope dyeing with controlled oxidation to decrease crocking.

Try foam dyeing or electrochemical reduction to minimize back-staining.

Add anti-back-staining agents and follow proper wash protocols.

Adjust chemical formulas and tension during dyeing for batch consistency.

Note: Dry garment processes with sodium hydroxide and heat treatment can create fashionable faded effects without uneven color.

Shrinkage Problems

Shrinkage affects fit and comfort. You can manage shrinkage with these best practices:

Best Practice | Description |

|---|---|

Washing Techniques | Use warm or hot water for even shrinkage. |

Precision Sizing | Adjust sizing before shrinking for proper fit. |

Maximize Heat | Use high heat in the dryer to lock in shrinkage. |

Fabric Knowledge | Know your denim’s composition to predict shrinkage. |

Post-Shrinking Care | Hand wash in cold water and air dry to maintain fit. |

Tip: Turn jeans inside out and use mild soap to protect color and fibers.

Stitching Defects

Stitching problems can weaken your jeans. You can fix common defects with these steps:

Use the correct needle size and type for denim.

Adjust thread tension to prevent skipped or loose stitches.

Maintain machines and replace worn parts for even stitching.

Match thread type with fabric weight to avoid puckering.

Train operators to spot and fix issues quickly.

Remember: Regular machine cleaning and operator training help prevent most stitching defects.

You gain many advantages when you follow denim fabric quality control at every stage. A strong checklist helps you deliver consistent size, color, and quality, which builds customer trust and loyalty. You also reduce costly rework and returns. See the benefits in the table below:

Benefit | Description |

|---|---|

Increased Durability | Synthetic fibers enhance strength and resistance to wear, making denim less likely to tear. |

Enhanced Color Retention | Synthetic fibers help maintain color vibrancy and prevent fading over time. |

Reduced Shrinkage and Wrinkling | Blending with polyester improves stability, reducing shrinkage and wrinkling after washes. |

Improved Comfort and Fit | Adding spandex allows for stretch, enhancing comfort and fit for various styles of jeans. |

You should apply denim fabric quality control steps now and review your process often. Regular inspections, clear standards, and customer feedback help you improve with each batch.

FAQ

What is the most important denim quality check?

You should always start with fabric evaluation. This step helps you catch weaving defects, shade issues, and other problems before production begins. Early checks save time and prevent costly mistakes.

How often should you inspect denim during production?

You need to inspect denim at every key stage. Check fabric before cutting, during sewing, and after finishing. Regular inspections help you catch defects early and keep your quality high.

Why does denim shrink after washing?

Denim shrinks because cotton fibers contract when exposed to water and heat. You can control shrinkage by using pre-shrunk fabrics and following recommended washing methods.

How can you prevent color fading in denim?

Tip: Wash jeans inside out in cold water. Use mild detergent and avoid direct sunlight when drying. These steps help you keep denim color vibrant for longer.